Refloating ship for floating rubbish

A technology for salvaging ships and garbage, applied in special-purpose ships, cleaning of open water surfaces, ships, etc., can solve the problems of difficult promotion, slow salvage speed, low efficiency, etc., to achieve a wide range of applications, fast cleaning speed, occupation small space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

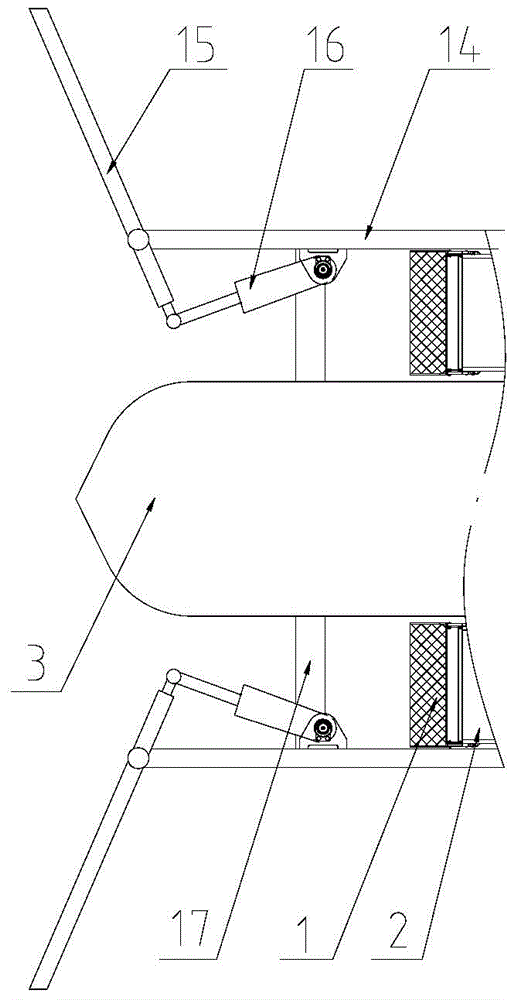

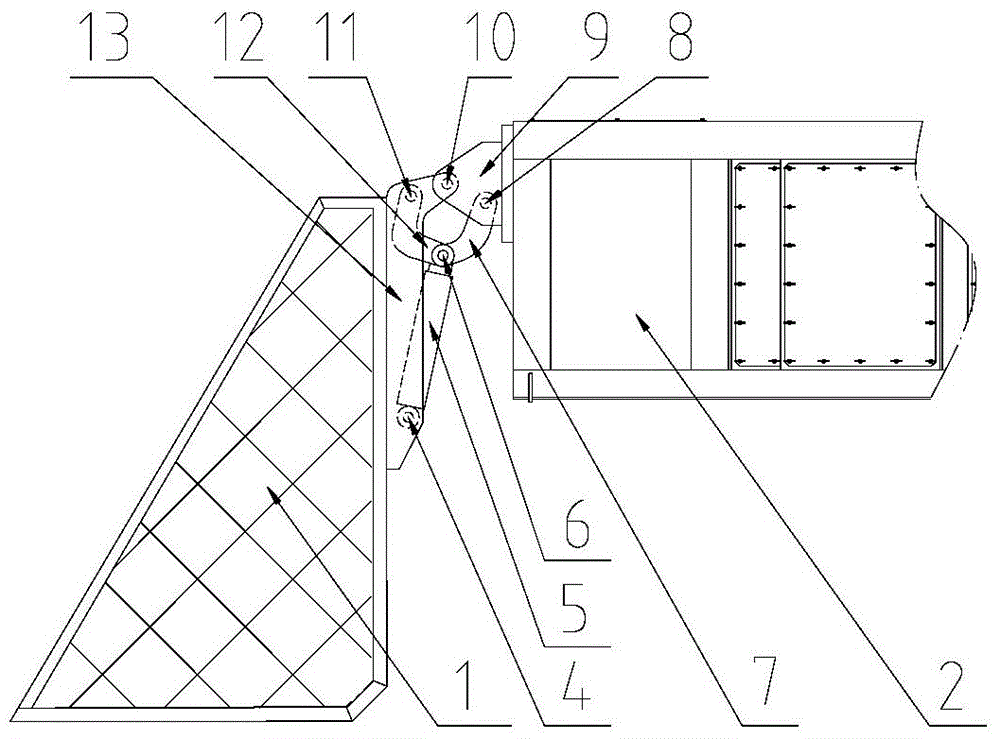

[0018] see figure 1 , figure 2 , which is a preferred embodiment of a floating garbage salvage ship, includes a hull 3, the two sides of the hull 3 are respectively provided with garbage collecting racks, and the garbage collecting racks include an upright vertical longitudinally extending along the hull 3 The plate 14 and the two longitudinal plates 14 are respectively fixedly connected to the hull 3 through a plurality of connecting plates 17, and the two ends of each connecting plate 17 are respectively fixedly connected to the hull and the longitudinal plates by bolts. A slanted plate 15 is erected at the front end of each longitudinal plate 14 respectively, the middle part of the slanted plate 15 is hinged with the longitudinal plate 14, and the front end of the slanted plate 15 extends along the side front of the corresponding side of the hull 3, and the slanted plate 15 An adjustment oil cylinder 16 is arranged between the rear end and the inner side wall of the longi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com