Biological fertilizer fermentation tank

A fermenter and bio-fertilizer technology, applied to bio-organic part treatment, organic fertilizers, fertilization devices, etc., can solve problems affecting fermentation quality, dry or wet biological fertilizers, etc., and achieve high-quality bio-fertilizer production and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

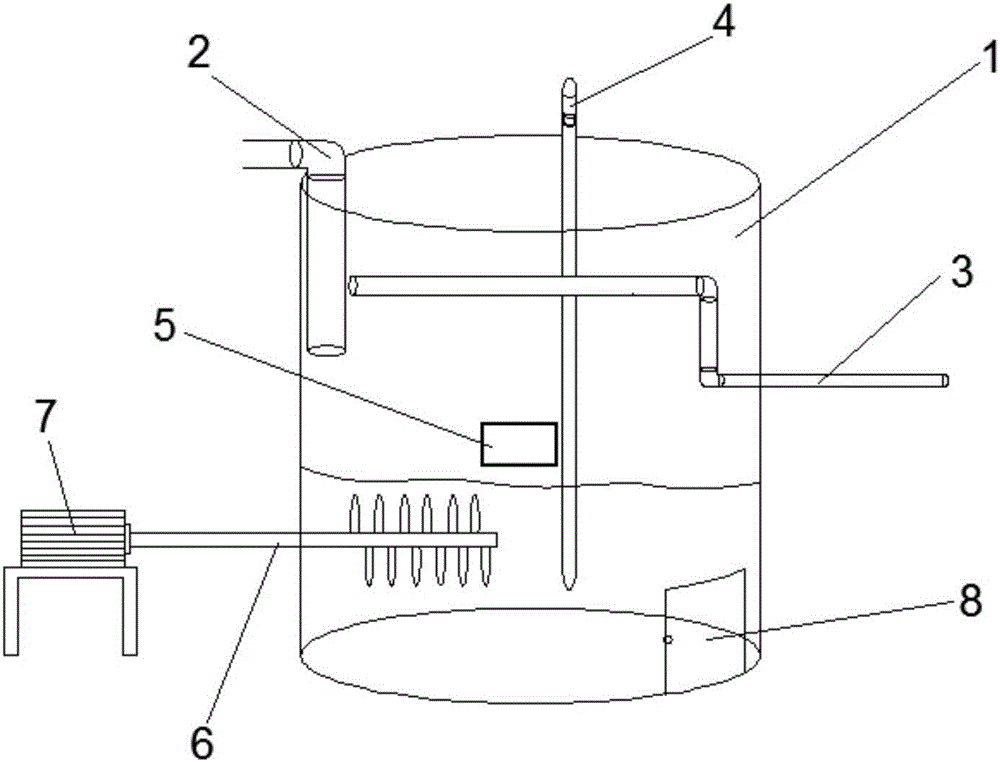

[0015] With reference to accompanying drawing, in order to make the present invention reach required technical effect, the present invention adopts following embodiment: a kind of bio-fertilizer fermenter comprises fermenter, motor, feeding pipe and water pipe, and its described fermenter is provided with feed The feed port is connected to the feed pipe, the fermenter is provided with a water inlet, the water inlet is connected to the water pipe, the water pipe has a water spray hole, and the fermenter is provided with a thermometer. The fermenter is equipped with a bearing, one end of the bearing is equipped with a stirring blade, the other end of the bearing is connected to a motor, the fermenter is provided with an observation window, and the fermenter is provided with a discharge port.

[0016] Preferably, the fermenter is a seamless tank.

[0017] Preferably, the feed pipe is located at the top of the fermenter, and the feed pipe is seamlessly connected with the fermenter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com