Stage extraction method for rose essential oil

A technology of rose essential oil and rose, which is applied in the direction of essential oil/fragrance, fat production, etc. It can solve the problems of difficult collection, loss of top fragrance, low yield, etc., and achieve the effect of ensuring quality and increasing the output of essential oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific embodiments.

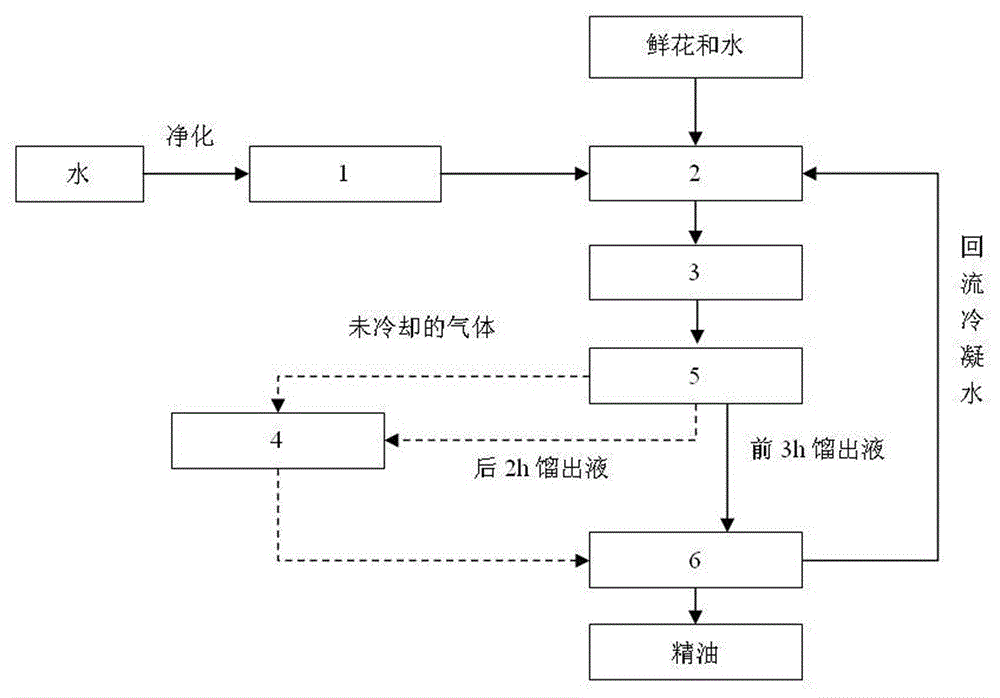

[0020] like figure 1 Shown is the distillation process of the present invention, which specifically includes the following steps:

[0021] (1) Inject purified groundwater into still 2, the amount of water is three times that of fresh flowers, put fresh flowers into still 2 that has been filled with water, and cover with a sealed cover (generally, the input amount of fresh flowers is 450kg per pot);

[0022] (2) Open the steam valve, pass steam into the still 2 through the steam boiler 1 to heat, the steam flow rate is controlled at 250L / h, when the temperature in the still 2 reaches 60-65°C, the steam flow rate remains unchanged, open a The condensed water of the primary condenser 3 and the secondary condenser 4 is opened at the same time the gas valve of the shunt tank 5, so that the uncooled gas through the primary condenser 3 enters the secondary condenser 4, and passes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com