Surface treatment technology for stainless-steel triangular spiral packing

A spiral filler and surface treatment technology, applied in the direction of metal material coating process, etc., can solve the problems of limited amount of dissolved grease in aqueous solution, small batch processing capacity, heavy load, etc., and achieve improved surface performance of fillers and large batch processing capacity. , the effect of fast processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A stainless steel triangular spiral filler surface treatment process, the process comprises the following steps:

[0021] (1) Put the stainless steel triangular spiral packing into water, heat it to 50°C, add a degreasing agent, clean it with ultrasonic vibration for 10 minutes, and then rinse the stainless steel triangular spiral packing with water;

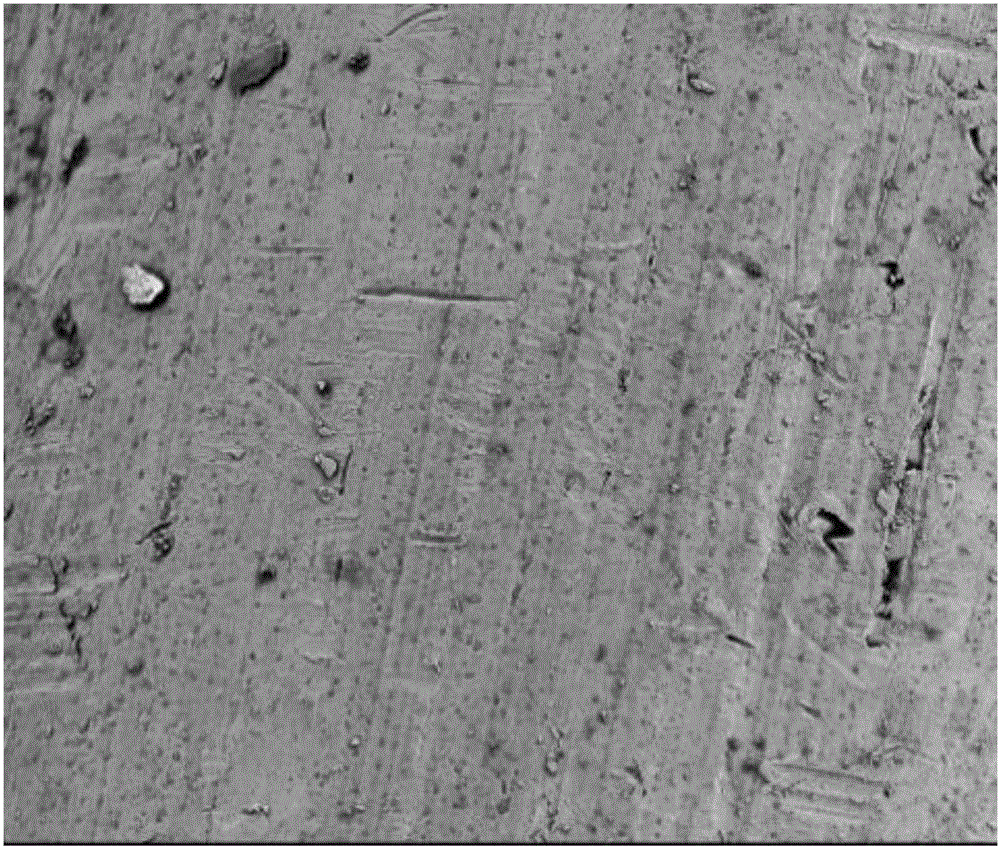

[0022] (2) Aqua regia and water are formulated into an aqueous solution according to a volume ratio of 1:10, and the stainless steel triangular spiral filler rinsed in step (1) is immersed in the aqueous solution, and pulled out after soaking for 24 hours;

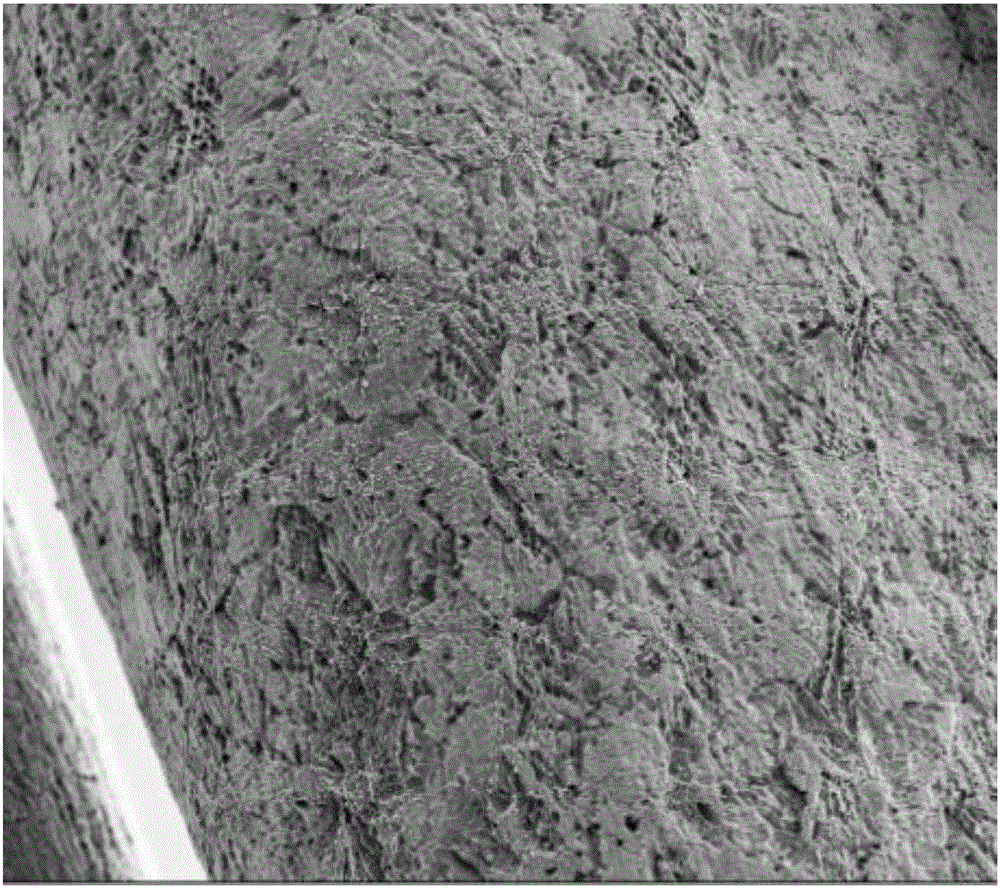

[0023] (3) put the stainless steel triangular spiral filler pulled out into 60°C aqua regia for oxidation treatment, and pull it out after the surface of the stainless steel triangular spiral filler loses its metallic luster;

[0024] (4) Clean the stainless steel triangular spiral packing with water until the pH value of the cleaning solution is neutral, then dry or ...

Embodiment 2

[0029] A stainless steel triangular spiral filler surface treatment process, the process comprises the following steps:

[0030] (1) Put the stainless steel triangular spiral packing into water, heat it to 60°C, add a degreasing agent, clean it with ultrasonic vibration for more than 20 minutes, and then rinse the stainless steel triangular spiral packing with water;

[0031] (2) Aqua regia and water are formulated into an aqueous solution according to a volume ratio of 1:20, and the stainless steel triangular spiral filler rinsed in step (1) is immersed in the aqueous solution, and pulled out after soaking for 48 hours;

[0032] (3) put the stainless steel triangular spiral filler pulled out into 50°C aqua regia for oxidation treatment, and pull it out after the surface of the stainless steel triangular spiral filler loses its metallic luster;

[0033] (4) Clean the stainless steel triangular spiral packing with water until the pH value of the cleaning solution is neutral, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com