Hydraulic control valve assembly

A technology for hydraulic control valves and components, applied in the directions of lift valves, valve details, valve devices, etc., can solve problems such as failure to eliminate water hammer in pipelines, slow valve opening, and failure to protect the safety of pipeline systems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

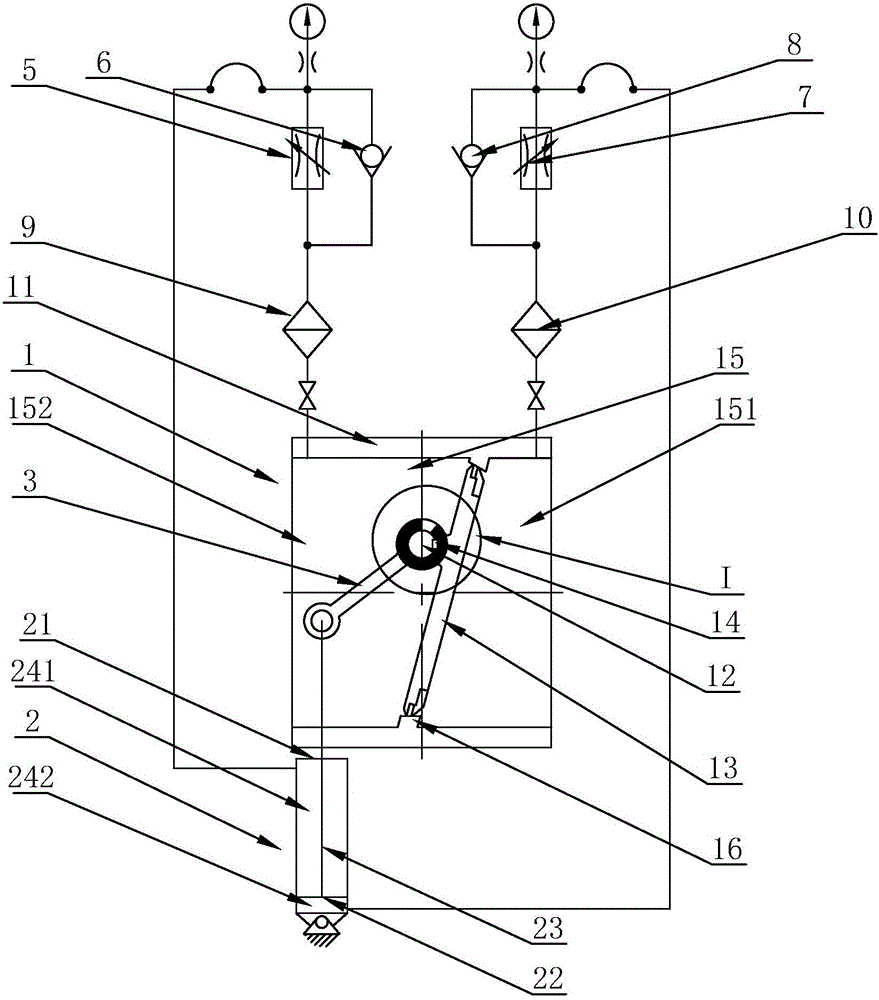

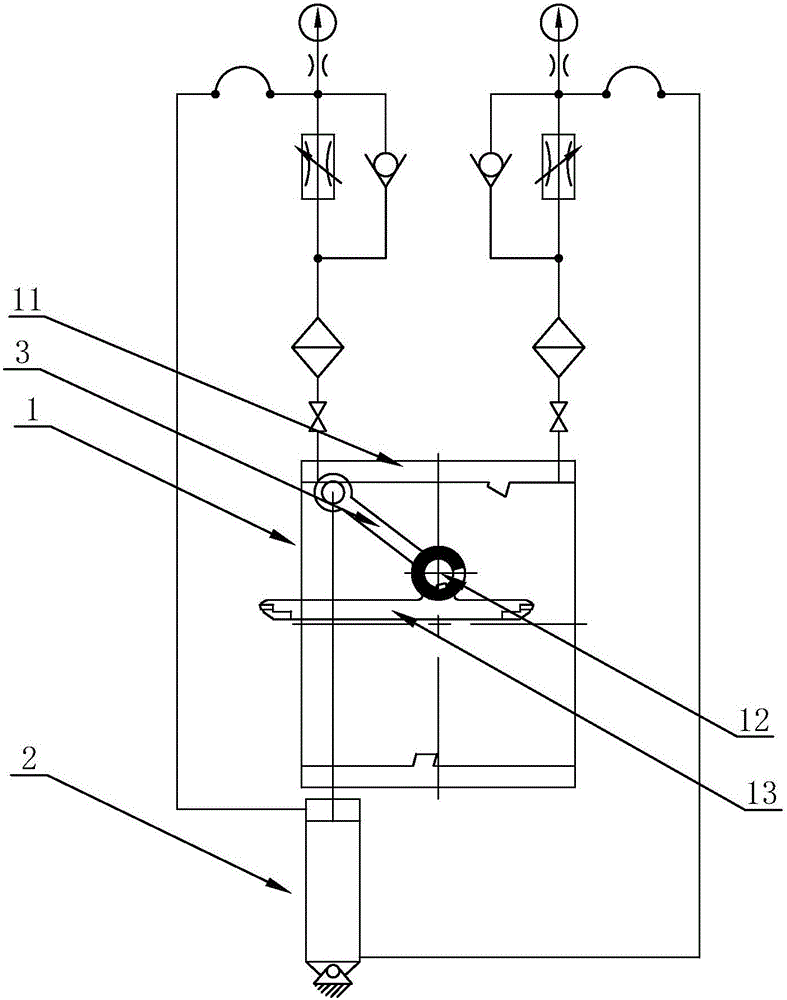

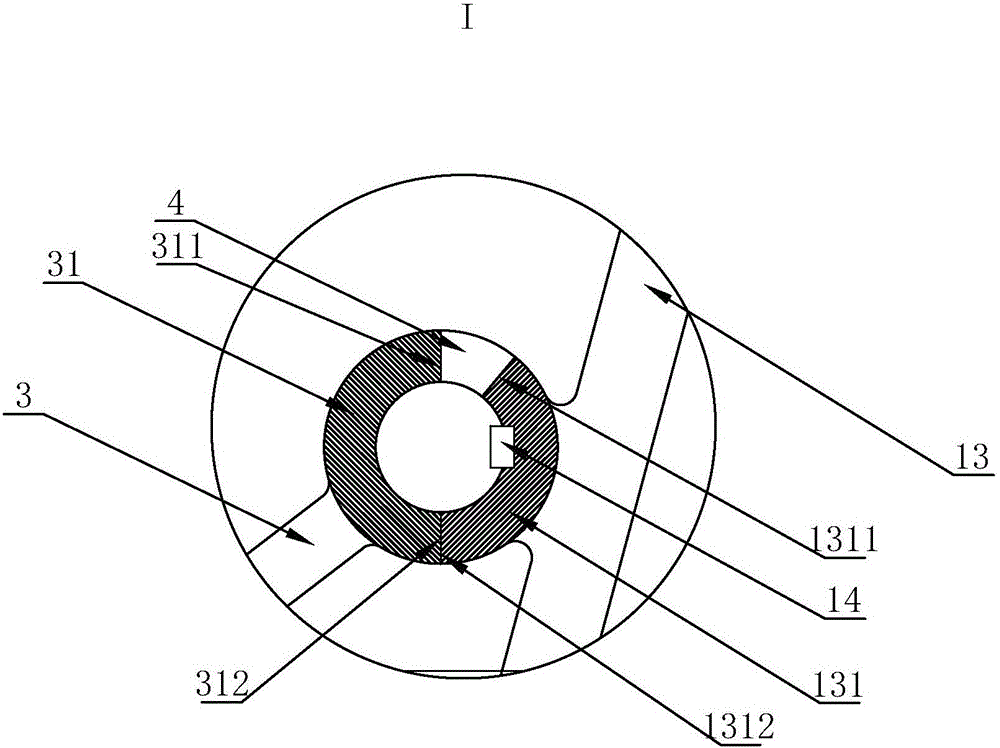

[0019] Such as figure 1 , 2 , 3, a hydraulic control valve assembly includes a control valve 1, a hydraulic cylinder 2, and a connecting rod 3, wherein the control valve 1 includes a valve body 11, a valve stem 12, a valve plate 13, and the valve stem 12 and the valve The body 11 rotates and fits, the valve plate 13 is sleeved on the valve stem 12, the valve plate 13 is connected with the valve stem 12 through the positioning key 14, the valve body 11 is provided with a medium flow channel 15, and one end of the medium flow channel 15 is an inlet port 151, The other end is the outlet end 152, and the valve plate 13 is located between the inlet end 151 and the outlet end 152. The said medium flow path 15 is provided with an annular sealing platform 16, and the valve plate 13 forms a seal with the inner surface of the annular sealing platform 16. The hydraulic cylinder 2 includes a cylinder body 21, the cylinder body 21 is provided with an inner cavity, and the inner cavity is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com