Corrosion-resistant hard alloy and application thereof in aspect of preparation of artificial board saw

A cemented carbide, corrosion-resistant technology, used in other manufacturing equipment/tools, engine components, turbines, etc., can solve problems affecting the service life of artificial panel saws, general corrosion resistance, etc., to improve service life and corrosion resistance. Good, high hardness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

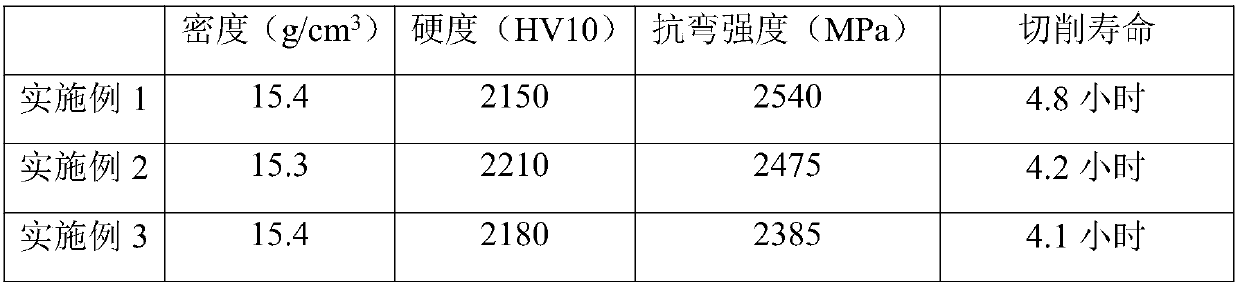

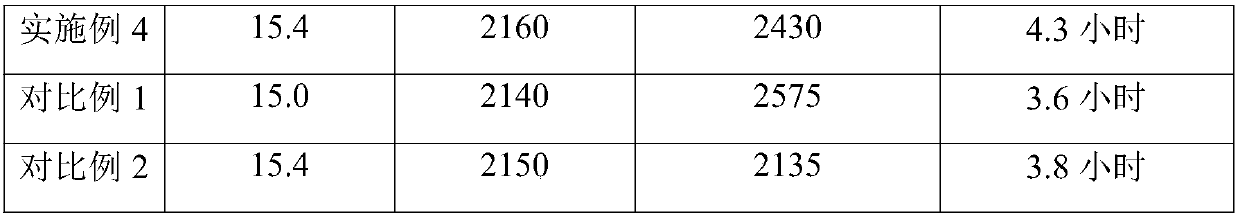

Examples

Embodiment 1

[0027] This embodiment provides a method for preparing an artificial panel saw, comprising the following steps:

[0028] S1. Mix cemented carbide and polyethylene glycol evenly and then perform ball milling. The main components and mass percentages of cemented carbide are: 1.5% Co, 0.5% Ni, 0.35% Cr 3 C 2 , 0.1% Re, the balance is 0.4μmWC; the amount of polyethylene glycol is 2% of the cemented carbide;

[0029] S2. Put the mixed material after ball milling in the step S1 into the saw blade mould, and press to form. Molding pressure is 65MPa;

[0030] S3. Vacuum sintering the saw blade substrate blank and the saw blade serration blank, the sintering process parameters are as follows: the temperature is 1450°C, and the time is 60min to obtain the saw blade substrate and saw blade teeth;

[0031] S4. Weld the saw teeth on the saw blade substrate, grind and coat the saw blade to obtain a wood-based panel saw.

Embodiment 2

[0033] This embodiment provides a method for preparing an artificial panel saw, comprising the following steps:

[0034] S1. Mix cemented carbide and polyethylene glycol evenly before ball milling, wherein the main components and mass percentages of cemented carbide are: 1.5% Co, 0.9% Ni, 0.3% Cr 3 C 2 , 0.3% Re, the balance is 0.2μmWC; the amount of polyethylene glycol is 2% of the cemented carbide;

[0035] S2. Put the mixed material after ball milling in the step S1 into the saw blade mould, and press to form. Molding pressure is 80MPa;

[0036] S3. Vacuum sintering the saw blade substrate blank and the saw blade sawtooth blank, the sintering process parameters are as follows: the temperature is 1450°C, and the time is 60min to obtain the saw blade sawtooth;

[0037] S4. Weld the saw teeth on the saw blade substrate, grind and coat the saw blade to obtain a wood-based panel saw.

Embodiment 3

[0039] This embodiment provides a method for preparing an artificial panel saw, comprising the following steps:

[0040] S1. Mix the cemented carbide and polyethylene glycol evenly and then perform ball milling. The main components and mass percentages of the cemented carbide are: 1.08% Co, 0.225% Ni, 0.075% Cr 3 C 2 , 0.12% Re, the balance is 0.4μmWC; the amount of polyethylene glycol is 2% of the cemented carbide;

[0041] S2. Put the mixed material after ball milling in the step S1 into the saw blade mould, and press to form. Molding pressure is 60MPa;

[0042] S3. Vacuum sintering the saw blade substrate blank and the saw blade sawtooth blank, the sintering process parameters are as follows: the temperature is 1450°C, and the time is 80min to obtain the saw blade sawtooth;

[0043] S4. Weld the saw teeth on the saw blade substrate, grind and coat the saw blade to obtain a wood-based panel saw.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com