Thermal insulation leakage-proof pipeline

A pipeline and leak-proof technology, which is applied in the direction of heat preservation, pipeline protection through heat insulation, pipeline protection, etc., can solve the problems of easy freezing and cracking, overflow and leakage, and inconvenient construction, so as to achieve good waterproof performance and anti-corrosion performance, and increase the service life , Improve the effect of antifreeze performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific embodiment of the present invention is described below in conjunction with accompanying drawing:

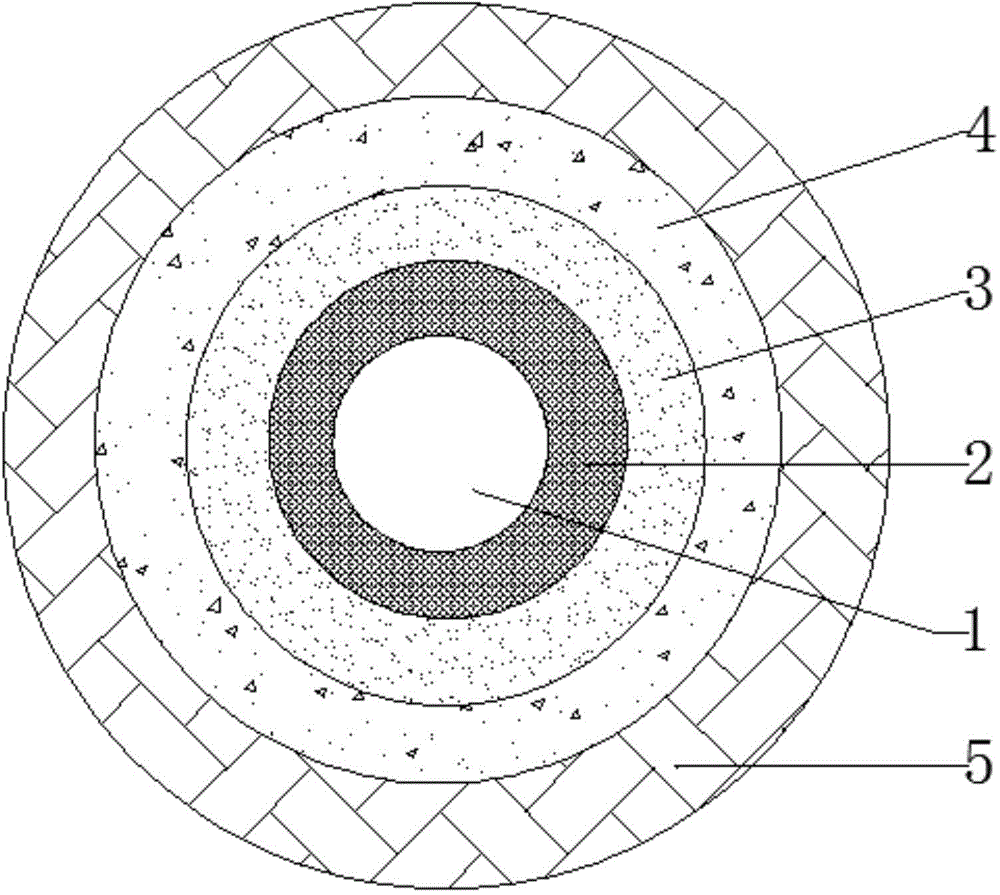

[0012] like figure 1 As shown, the invention includes a pipeline 1, an insulation layer 2, a hard protection layer 3, a soft protection layer 4 and a rigid protection cover 5. The outside of the pipeline 1 is provided with an insulation layer 2, and the outside of the insulation layer 2 is arranged in sequence. There is a hard protective layer 3 and a soft protective layer 4, and a rigid protective sheath 5 is arranged outside the protective layer.

[0013] The material of the hard protective layer 3 is hard polyurethane.

[0014] The material of the soft protective layer 4 is but not limited to asbestos or expanded perlite.

[0015] The rigid protective cover 5 is made of fiberglass or plexiglass.

[0016] An embodiment of the present invention has been described in detail above, but the content described is only a preferred embodiment of the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com