Medium-frequency power supply water cooling system

An intermediate frequency power supply, water cooling technology, applied in water shower coolers, cooling/ventilation/heating renovation, heat exchange equipment, etc., can solve the problem that the return water tank cannot be filled with water, the cooling tower is single, and the cooling system cannot be improved in time. efficiency and other issues to achieve the effect of improving work efficiency and preventing flow everywhere

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

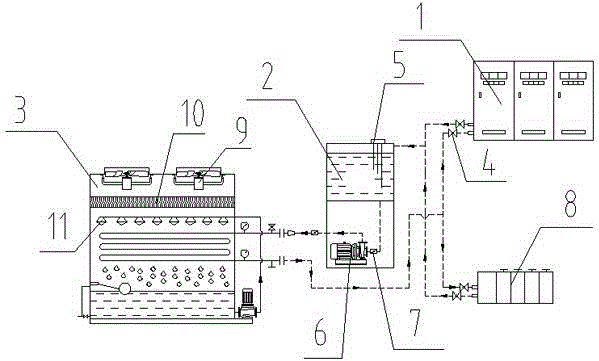

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

[0011] An intermediate frequency power supply water cooling system, which is provided with a power supply cabinet 1, a return water tank 2 and a cooling tower 3, the power supply cabinet 1 and the return water tank 2 are connected to each other, a connecting pipeline is provided between the cooling tower 1 and the return water tank 2, and the power supply cabinet 1 A control valve 4 is provided between the return tank 2, the control valve 4 is a ball valve, a liquid level control device 5 is provided in the return tank 2, a main motor 6 is provided at the lower part of the return tank 2, and a There is a solenoid valve 7, the solenoid valve 7 controls the opening and closing of the main motor 6, the solenoid valve 7 is connected with the liquid level control device 5, the liquid level control device 5 is provided with a liquid level sensing needle, and the liquid level ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com