Antipole detecting device used on aluminum electrolytic capacitor bushing machine

A technology of aluminum electrolytic capacitors and detection devices, applied in capacitor testing, capacitors, measuring devices, etc., can solve the problems of missed detection, inability to generate feedback from reverse polarity, and poor reverse polarity, so as to achieve accurate detection, reduce the risk of customer complaints, Stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

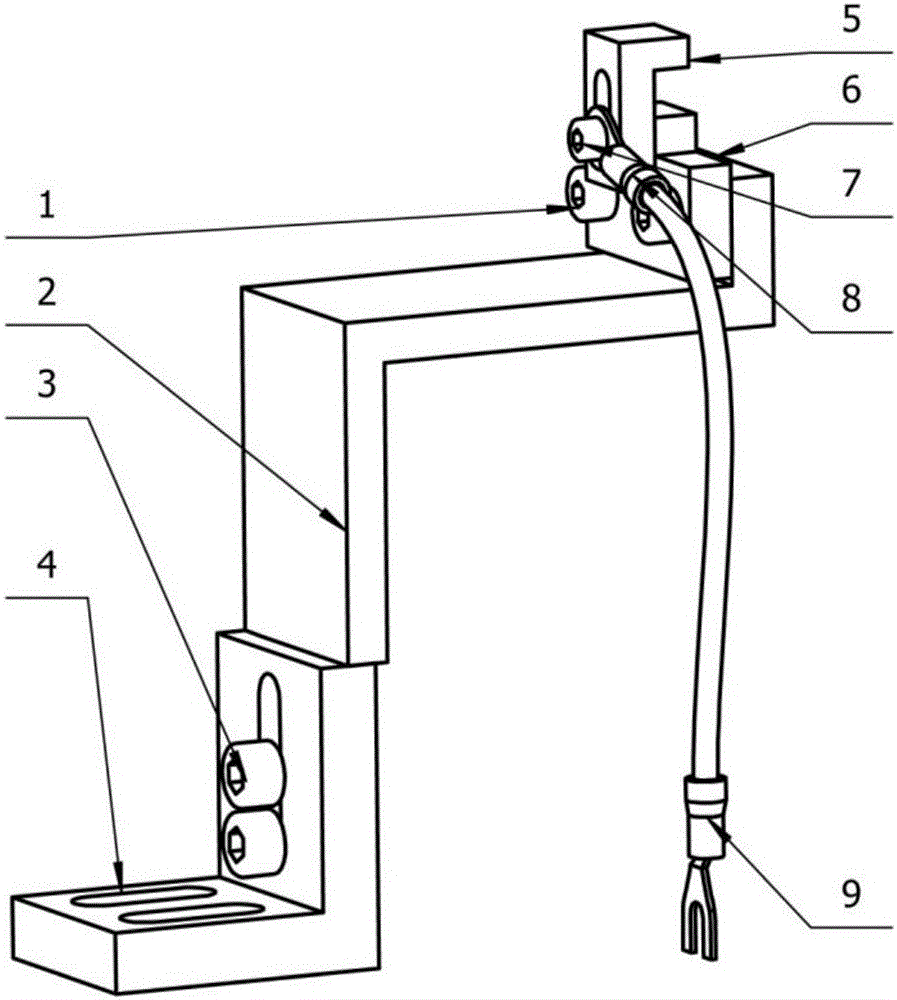

[0013] Such as figure 1 The shown reverse polarity detection device for aluminum electrolytic capacitor bushing machine includes a mounting bracket 2, a mounting base 4, an electrode block 5 and an insulating plate 6; the electrode block 5 is fixedly installed on the insulating plate 6, and the The insulating plate 6 is fixedly installed on the installation base 4 through the installation bracket 2, and the installation base 4 is fixedly installed on the table top of the casing machine; On the transmission path, and the distance between the end surface of the detection end of the electrode block 5 and the cathode of the capacitor is smaller than the length difference between the positive and negative lead pins of the capacitor. During the production process of the casing machine, if the steering is not in place or the polarity is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com