Metal elastic contact

An elastic contact and elastic technology, applied in the direction of clamping/spring connection, coupling device, conductive connection, etc., can solve the problems of corrosion, conductive group conductivity weakening, melting, etc., to reduce manufacturing costs, avoid serious temperature rise, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

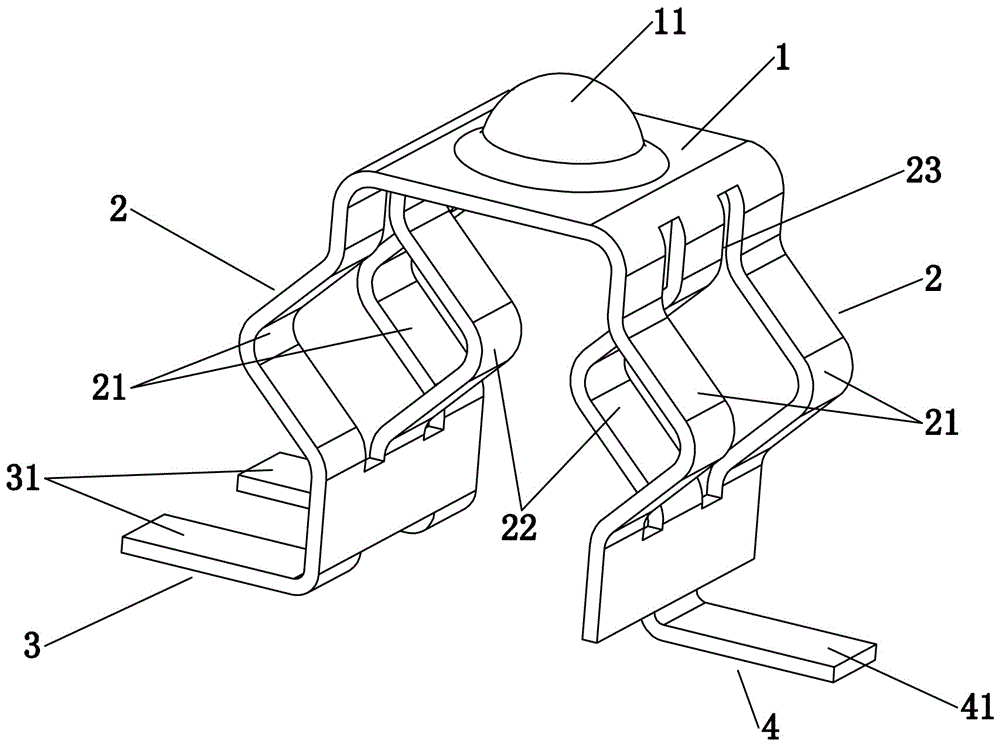

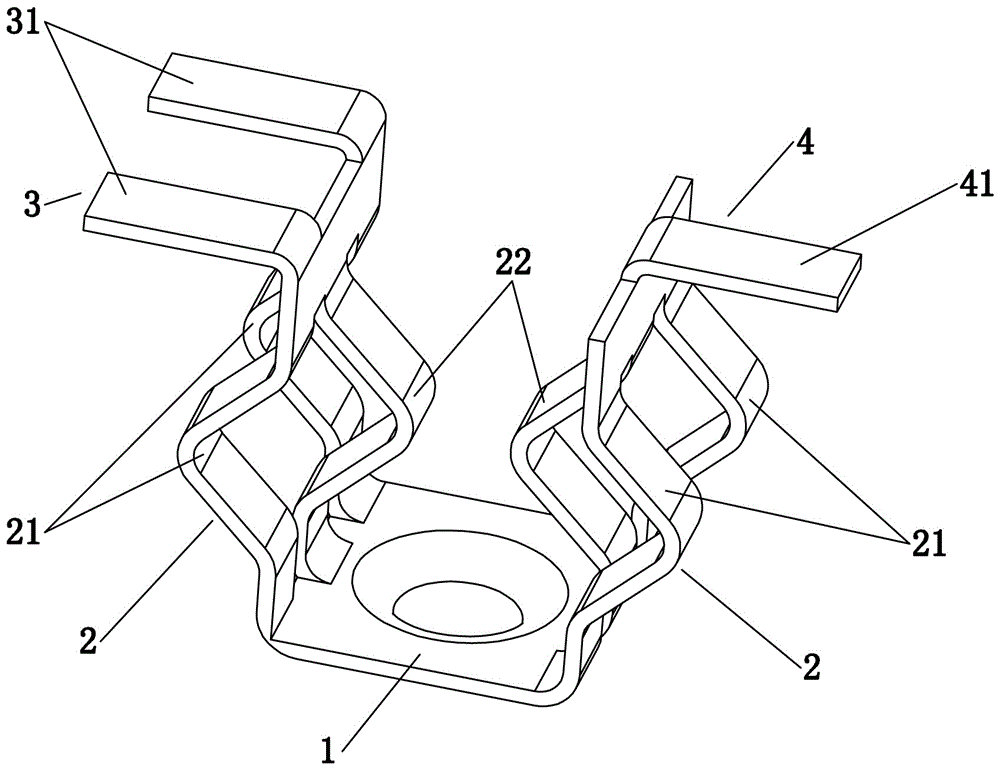

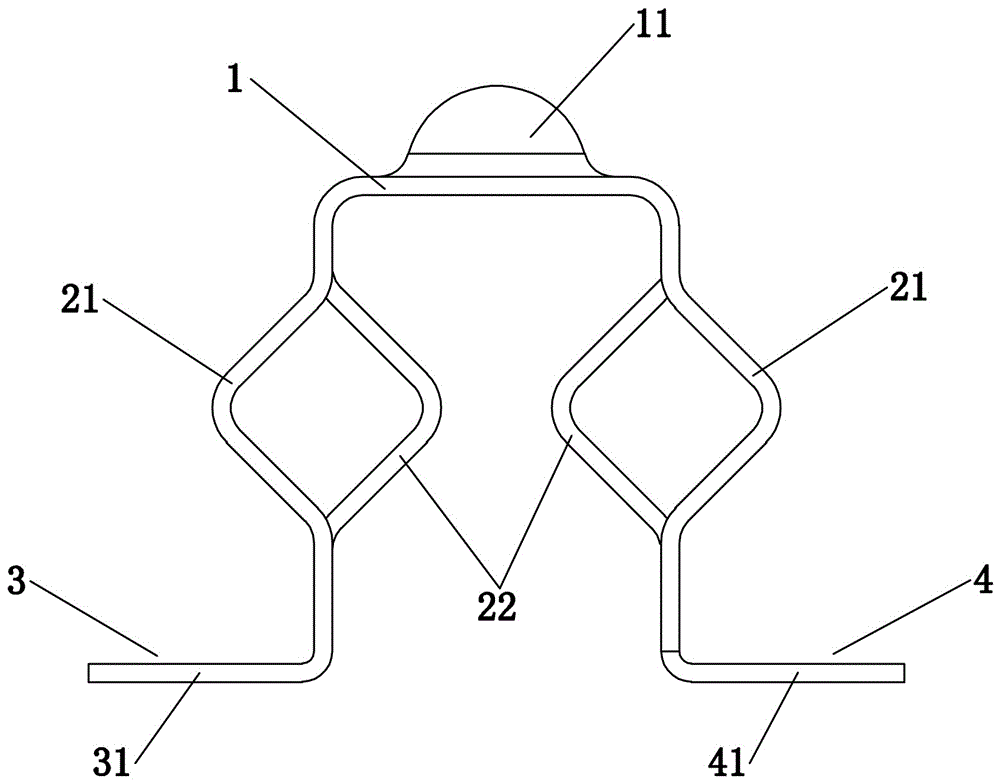

[0030] Embodiment one, see Figure 1 to Figure 3 As shown, a metal elastic contact includes an elastic contact bent from a metal sheet, and the elastic contact includes an elastic contact surface 1, an elastic support surface 2 and a fixed support arranged in sequence from top to bottom At least two edges of the elastic contact surface 1 are respectively provided with the elastic support surface 2, and the lower end of each elastic support surface 2 is provided with the fixed support surface.

[0031] The surface of the elastic contact surface 1 is provided with convex points 11 (or, the surface of the elastic contact surface 1 is provided with concave points 12, see Figure 4 with Figure 8 shown). The elastic contact surface 1 is square, and the elastic support surfaces 2 are respectively provided on the left and right edges.

[0032] The elastic support surface 2 is vertically provided with two separation grooves 23, and the two separation grooves 23 separate the elastic...

Embodiment 2

[0037] Embodiment two, the difference with embodiment one is: see Figure 7 As shown, the left fixed support foot 31 and the right fixed support foot 41 are both pin-type fixed support feet arranged vertically.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com