Metal Zipper Drawing Machine

A technology of metal zipper and wire drawing machine, which is applied in the direction of sliding fastener components, applications, fasteners, etc., and can solve the problems that metal zippers cannot be produced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The structure of the present invention will be further described below in conjunction with the accompanying drawings.

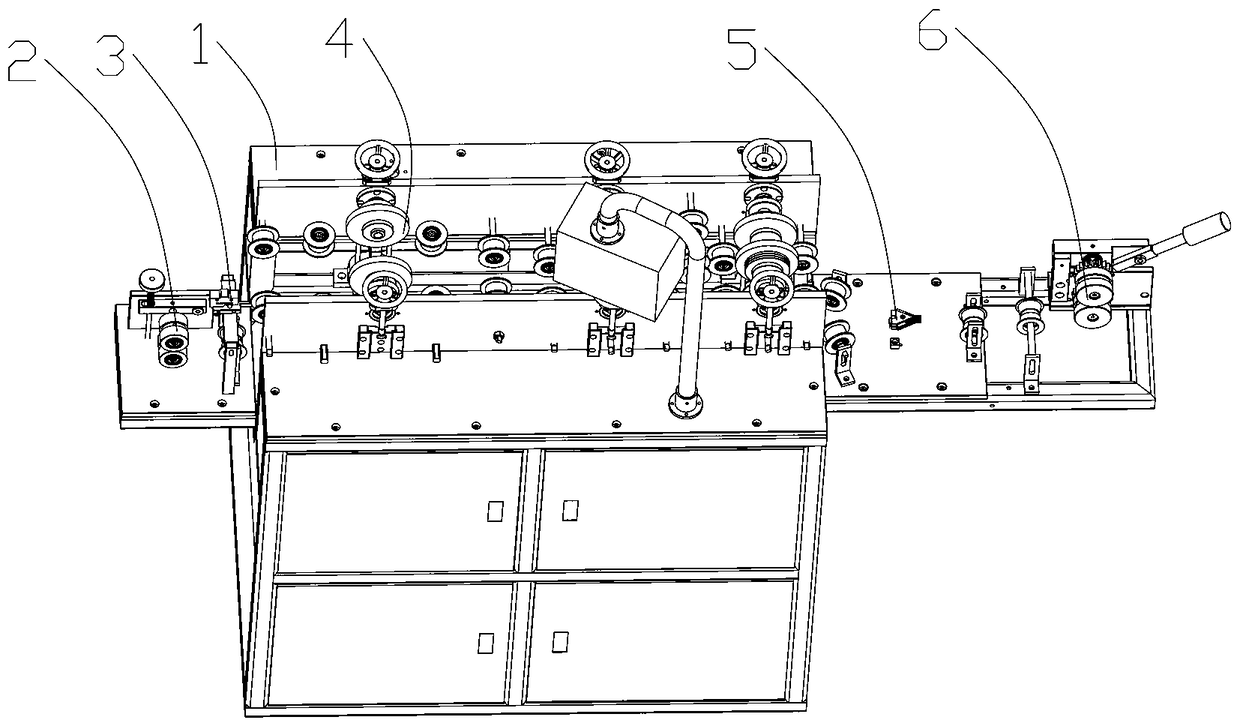

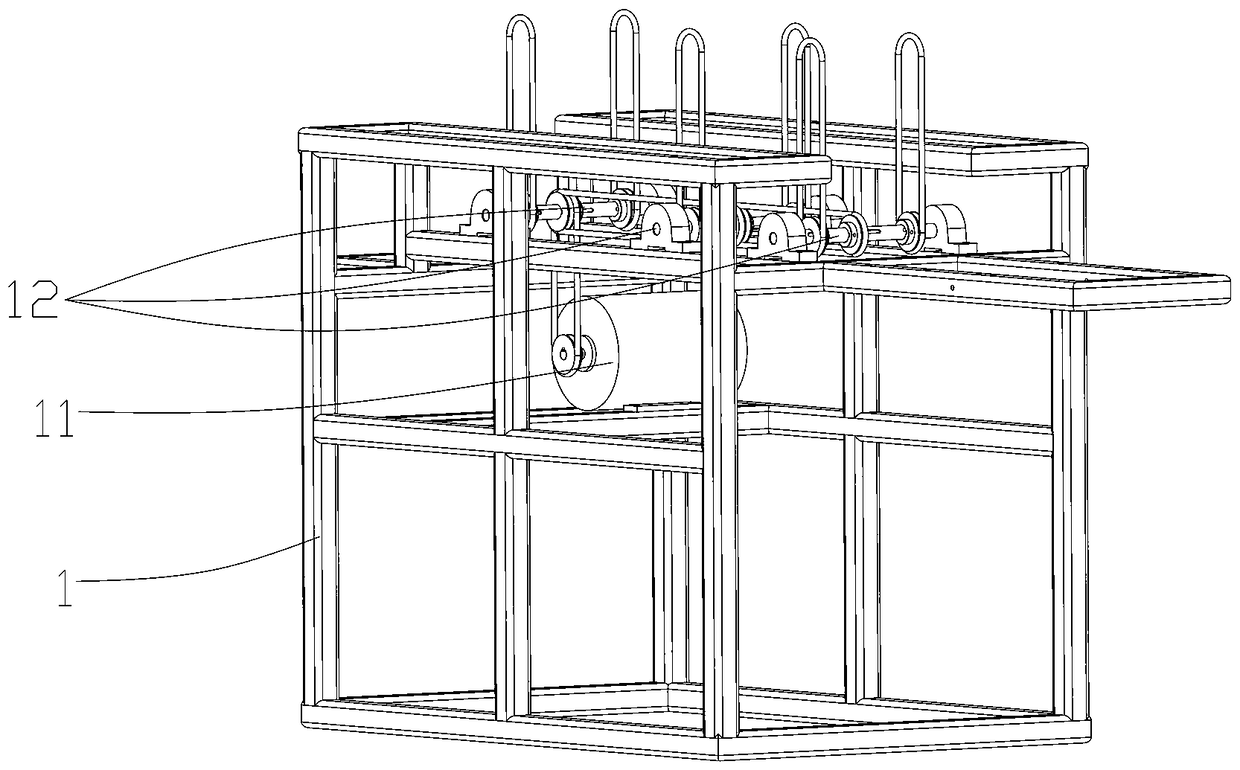

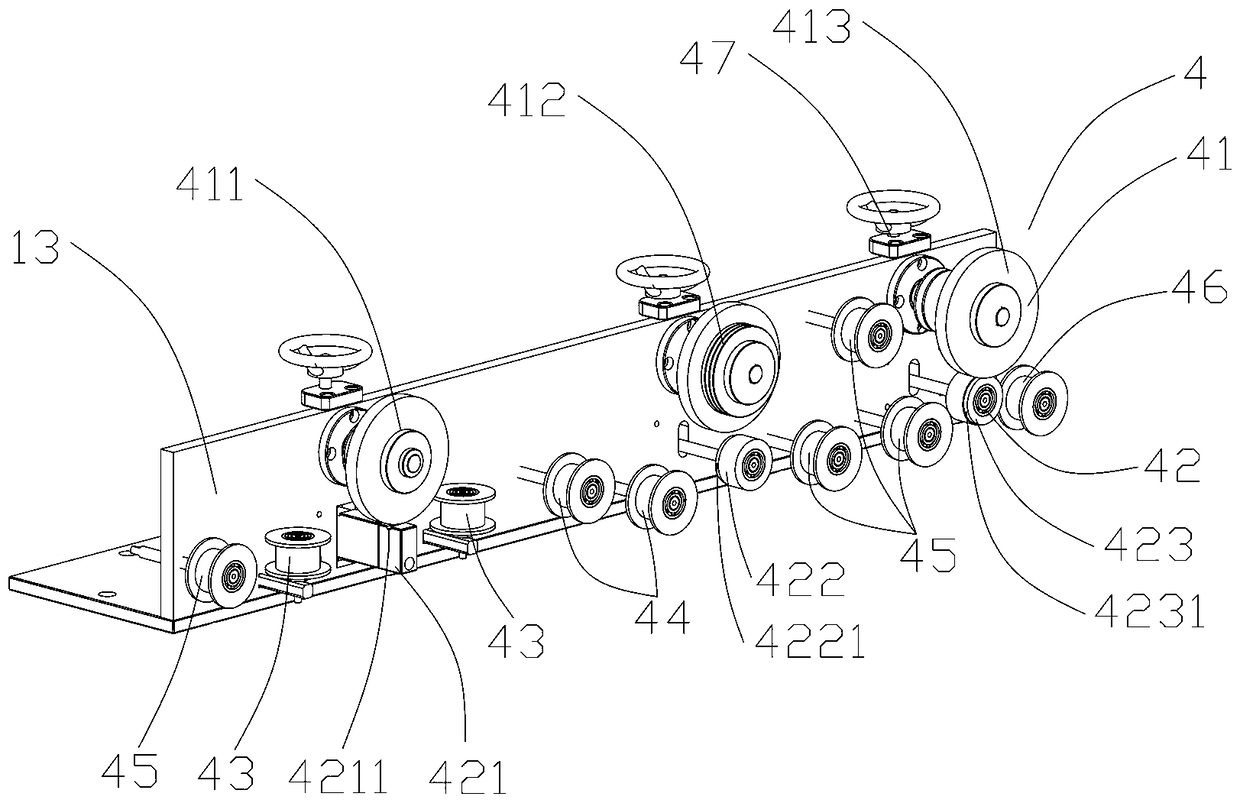

[0023] refer to Figure 1 to Figure 6 , the metal zipper wire drawing machine of the present invention includes a body 1, an introduction mechanism 2, a detection mechanism 3, two groups of mutually symmetrical wire drawing mechanisms 4, a chain closing mechanism 5 and a dragging mechanism 6, and the body 1 is a support mechanism of the present invention, Lead-in mechanism 2, detection mechanism 3, wire-drawing mechanism 4, chain closing mechanism 5 and towing mechanism 6 are installed on the fuselage 1 respectively, and lead-in mechanism 2 is arranged on the forefront of fuselage 1, is used for leading in the zipper closed, and coordinates The wire-drawing mechanism separates the closed zipper into two single-sided zippers and introduces them to two groups of wire-drawing mechanisms 4 respectively. The detection mechanism 3 is arranged above the intro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com