Wiredrawing UV color-coated sheet and preparation method thereof

A color-coated board and wire-drawing technology, which is applied in the field of metal composite materials, can solve the problems of flammability and explosion of oil-based paints and thinners, lack of color-coated wire-drawing functions, and physical injuries of operators, so as to achieve rich product types, Achieve product diversification and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

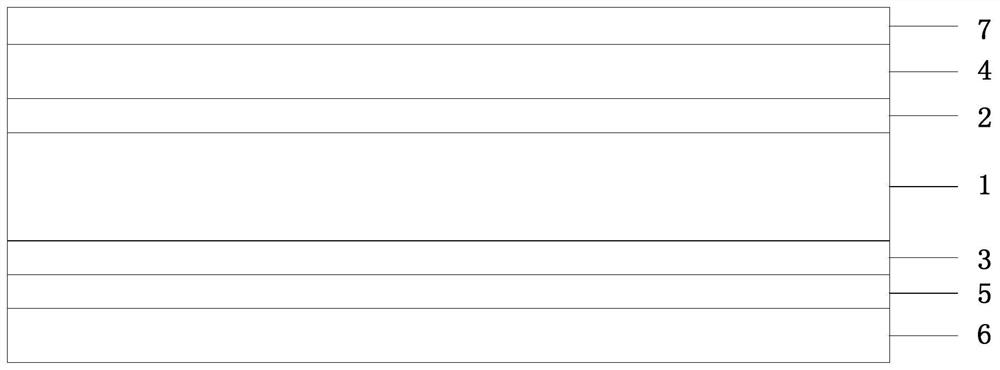

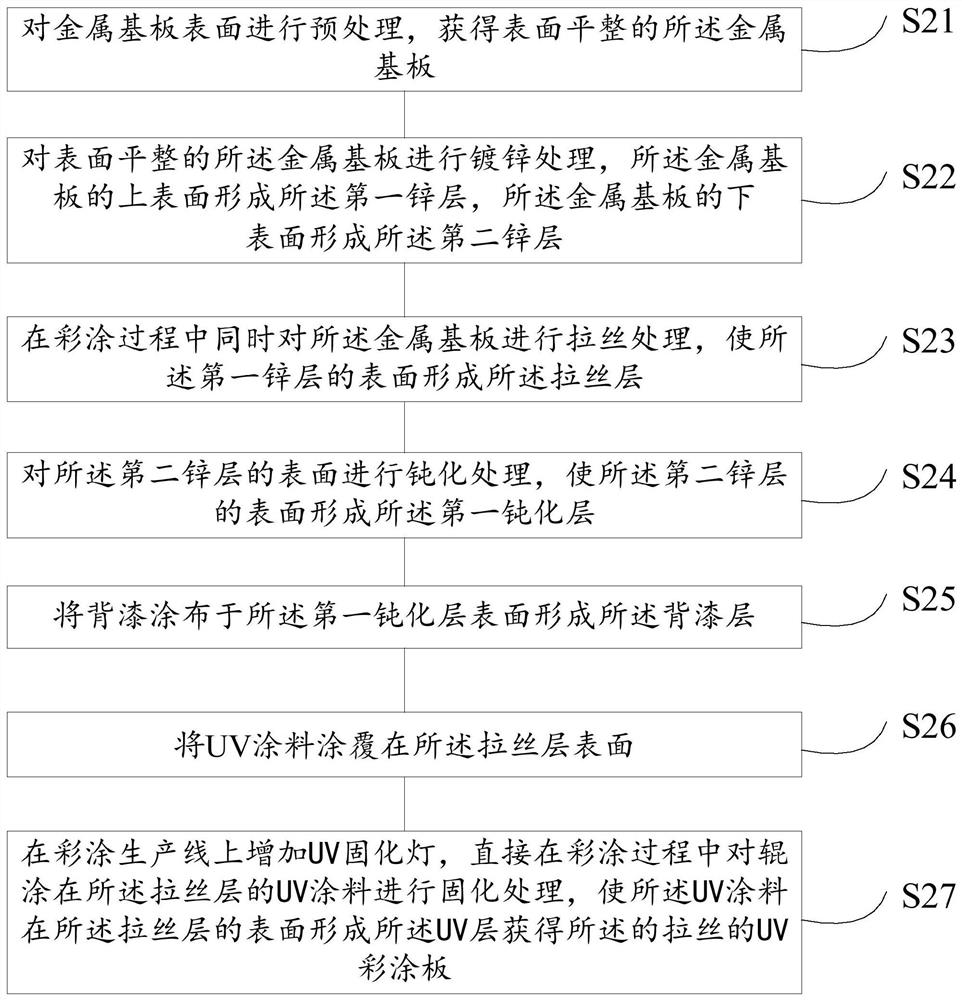

[0054] refer to figure 2 , showing a method for preparing the above-mentioned brushed UV color-coated sheet provided by an embodiment of the present application, including:

[0055] S21. Pretreating the surface of the metal substrate to obtain the metal substrate with a smooth surface;

[0056] S22. Galvanizing the metal substrate with a flat surface, the first zinc layer is formed on the first surface of the metal substrate, and the second zinc layer is formed on the second surface of the metal substrate;

[0057] S23. Simultaneously performing wire drawing treatment on the metal substrate during the color coating process, so that the wire drawing layer is formed on the surface of the first zinc layer;

[0058] S24. Passivating the surface of the second zinc layer to form the first passivation layer on the surface of the second zinc layer;

[0059] S25, coating a back paint on the surface of the first passivation layer to form the back paint layer;

[0060] S26, coating U...

Embodiment 1

[0083] In specific embodiment 1, the UV color-coated plate of described drawing and preparation method thereof, comprise:

[0084] The metal substrate 1 with a thickness of 1.5 mm is uncoiled, welded, and pre-cleaned with pure water. After the pre-cleaning, loop rolling is performed, and the cooled metal substrate 1 is surface restored by electroplating to obtain a flat surface. The metal substrate 1;

[0085] The metal substrate 1 with a flat surface is immersed in a hot-dip galvanizing tank to form a surface density of 10g / m 2 The first zinc layer 2 and the second zinc layer 3 are cooled, and the surface of the first zinc layer 2 and the second zinc layer 3 is finished by polishing;

[0086]Add a wire drawing device on the color coating production line, use a scouring pad as a consumable to directly carry out wire drawing treatment on the surface of the first zinc layer 2 in the color coating process, and adjust the pressure of the scouring pad to obtain a continuous straig...

Embodiment 2

[0092] In specific embodiment 2, the UV color-coated plate of described drawing and preparation method thereof, comprise:

[0093] The metal substrate 1 with a thickness of 0.75 mm is uncoiled, welded and pre-cleaned with pure water, and then loop-rolled after the pre-cleaning, and the cooled metal substrate 1 is subjected to surface reduction by means of electroplating to obtain a smooth surface. The metal substrate 1;

[0094] The metal substrate 1 with a flat surface is immersed in a hot-dip galvanizing tank to form a surface density of 150g / m 2 The first zinc layer 2 and the second zinc layer 3 are cooled, and the surface of the first zinc layer 2 and the second zinc layer 3 is finished by polishing;

[0095] Add a wire drawing device on the color coating production line, use a scouring pad as a consumable to directly perform wire drawing treatment on the surface of the first zinc layer 2 during the color coating process, and adjust the pressure of the scouring pad to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com