Bactericidal gray composite coating, preparation method thereof and gray bactericidal product

A technology of composite coating and sterilization layer, applied in the field of sterilization, can solve the problem of high cost of gray coating layer, and achieve the effect of good broad-spectrum sterilization effect and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

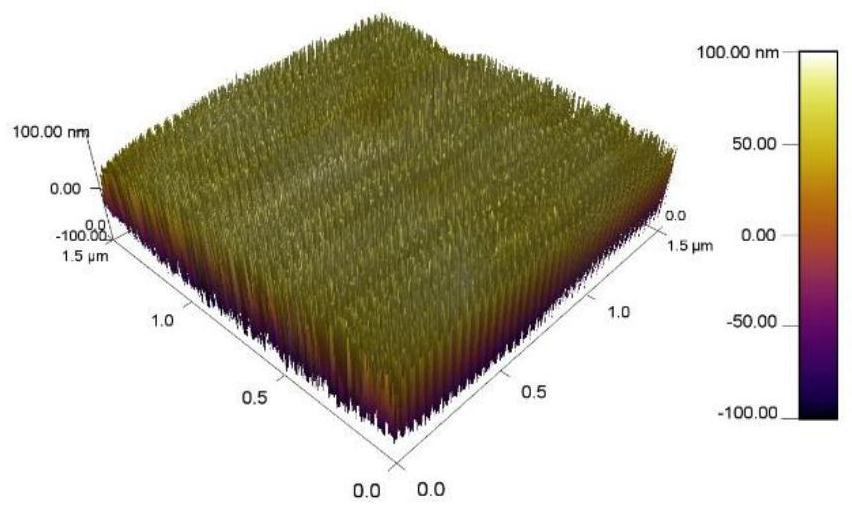

Image

Examples

preparation example Construction

[0049] The present application also provides the preparation method of the above-mentioned bactericidal gray composite coating, including:

[0050] (1) Pre-treatment of the substrate: including polishing and cleaning;

[0051] (2) electroplating the high-sulfur nickel layer on the surface of the pretreated substrate;

[0052] Optionally, (3) wire drawing the high-sulfur nickel layer;

[0053] (4) Electroplating the gray composite bactericidal layer on the surface of the high-sulfur nickel layer obtained in step (2) or the high-sulfur nickel layer obtained in step (3) after wire drawing.

[0054] In the embodiments of the present application, the cleaning treatment in the pretreatment described in step (1) may include fine cleaning processes such as wax removal, oil removal, electrolysis, and pure water cleaning.

[0055] In the embodiment of the present application, the conditions for electroplating the high-sulfur nickel layer in step (2) may include: a temperature of 45-55...

Embodiment 1

[0064] (1) Pretreatment of electroplating

[0065] Polishing and fine cleaning (including wax removal, oil removal, electrolysis, pure water cleaning) of stainless steel substrates;

[0066] (2) Electroplating a high-sulfur nickel layer on the surface of the pre-treated substrate

[0067] The electroplating solution for forming the high-sulfur nickel layer includes: nickel sulfate with a concentration of 380g / L, nickel chloride with a concentration of 70g / L, boric acid with a concentration of 45g / L, and 90% of the high-sulfur nickel HAS with a concentration of 3mL / L;

[0068] The electroplating process conditions include: the temperature is 50°C, the voltage is 8V, and the cathode current density is 5A / dm 2 , the plating time is 1800s;

[0069] (3) Drawing the high-sulfur nickel layer

[0070] The process conditions of wire drawing include: the wire drawing wheel is a nylon wheel, the speed of the wire drawing machine is 350rpm, and the wire drawing time is 15s;

[0071] (...

Embodiment 2

[0075] The preparation method is basically the same as that of Example 1, except that in the electroplating solution used in the electroplating of the gray composite bactericidal layer in step (4), the concentration of cetyltrimethylammonium iodide is 100 g / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com