Screw and normal juice machine

A juicer and screw technology, applied in the field of food processing, can solve the problems of increasing the weight of the screw 1', poor user experience, waste of materials, etc., and achieve the effects of convenient assembly, reduced processing difficulty, and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

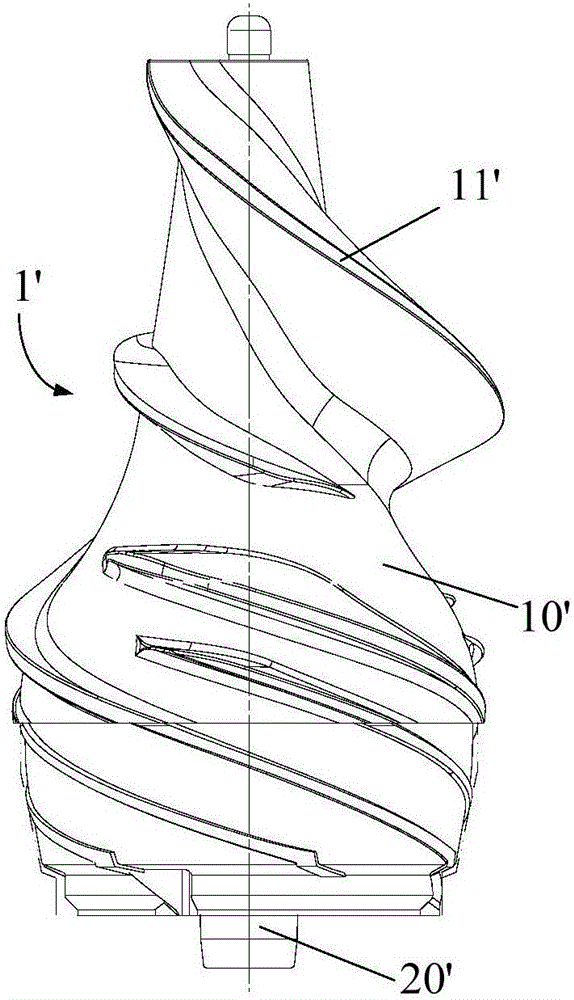

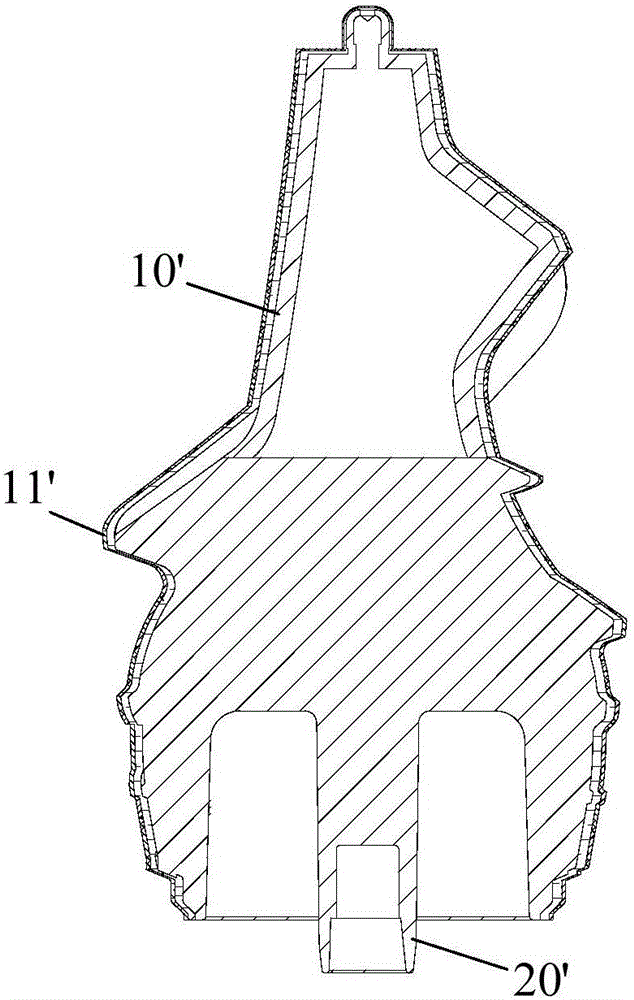

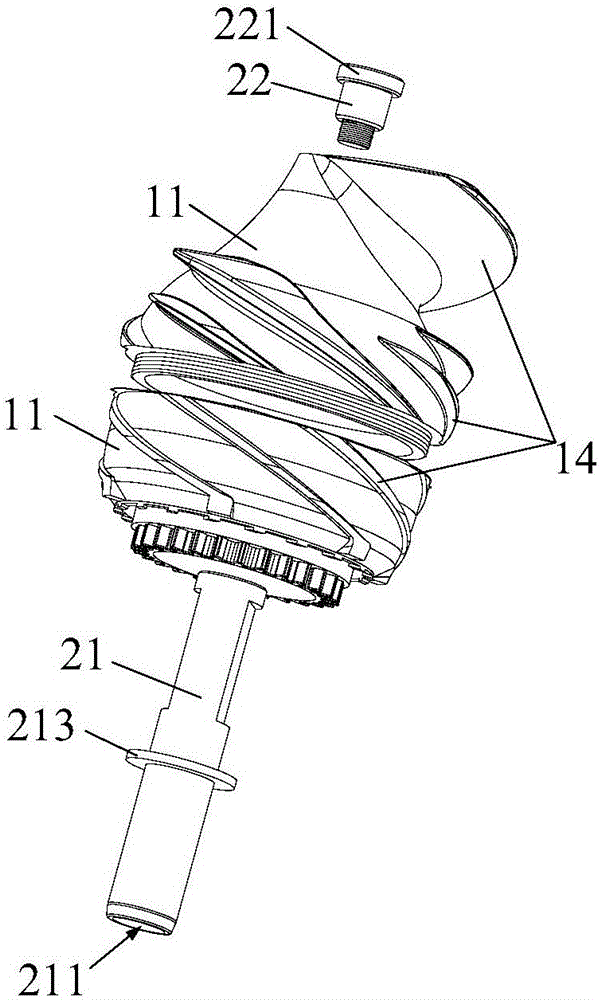

[0086] Such as Figure 3 to Figure 6 As shown, the screw 1 includes a housing 10 and a rotating shaft 20, the housing 10 is provided with a support seat 12, the upper end of the housing 10 is provided with a counterbore 13, the horizontal wall surface of the counterbore 13 is a limiting surface 131, and The vertical wall surface of the head hole 13 is provided with a limit groove 132 along the vertical direction, and the casing 10 is horizontally segmented to form two upper and lower sub-housings 11, and the lower interface end of the upper sub-housing 11 is provided with an external thread , the upper interface end of the lower sub-housing 11 is provided with an internal thread; the rotating shaft 20 includes a shaft body 21 and an axial locking member 22, the lower end of the shaft body 21 is provided with a shaft hole 211, and the upper end is provided with a threaded hole 212, and The side wall in the middle is provided with a support plate 213; the lower end of the axial ...

Embodiment 2

[0089] Such as Figure 7 to Figure 10 As shown, the screw rod 1 includes a housing 10, a rotating shaft 20 and two buckles 30 with threaded holes 212. The housing 10 is provided with a support seat 12, and the upper end of the housing 10 is provided with a countersunk hole 13, and the countersunk hole The horizontal wall surface of 13 is a limit surface 131, and the vertical wall surface of the counterbore 13 is provided with a limit groove 132 along the vertical direction, and the housing 10 is longitudinally divided into two left and right sub-housings 11, and the two sub-housings 11 The upper and lower ends of the shaft are provided with external threads; the rotating shaft 20 includes a shaft body 21 and an axial locking member 22, the lower end of the shaft body 21 is provided with a shaft hole 211, and the upper end is provided with a threaded hole 212, and the side wall in the middle A support plate 213 is provided, the lower end of the axial locking member 22 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com