Dispensing and attaching machine

A technology of laminating machine and dispensing mechanism, which is applied in the direction of material gluing, mechanical equipment, connecting components, etc., can solve the problems of low work efficiency, increase labor cost, reduce work efficiency, etc., and achieve convenient operation, improve work efficiency, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

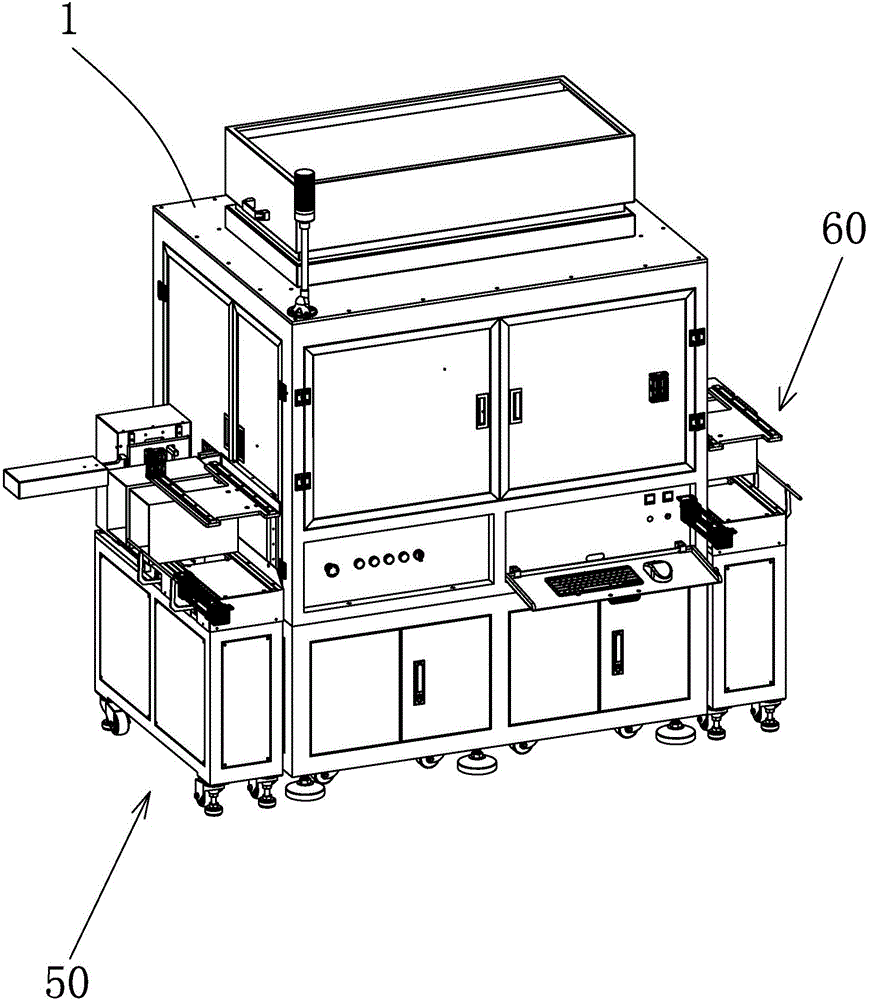

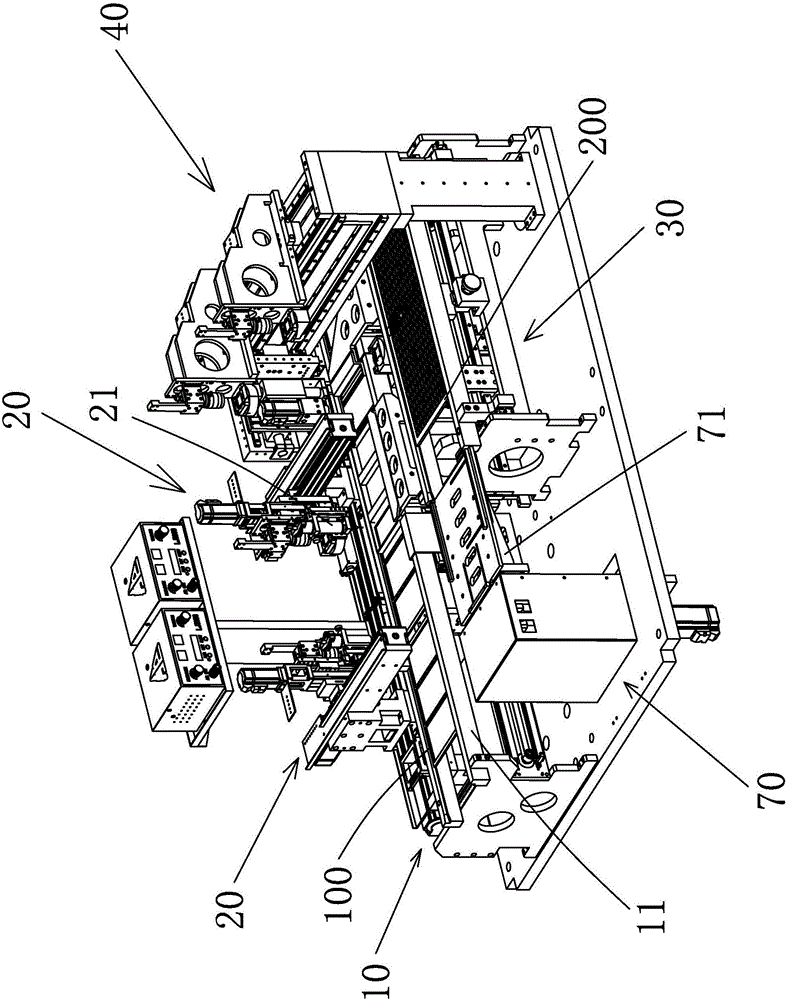

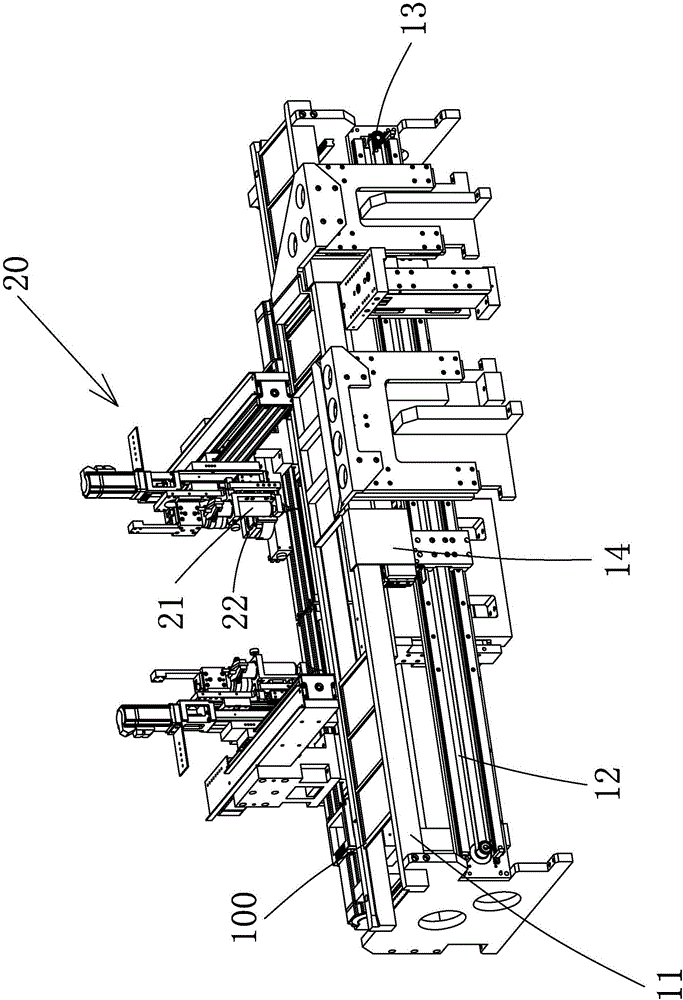

[0039] Dispensing laminating machine, see figure 1 and figure 2 As shown, the first conveying device 10 is included. The first conveying device 10 includes a first conveying mechanism and a working feeding track 11. The working feeding track 11 is arranged along the Y axis. The first conveying mechanism can drive the chip jig 100 on the working feeding track 11. reciprocating movement on

[0040] refer to figure 1 and figure 2 As shown, a dispensing device 20 and a laminating device 40 are sequentially provided along the direction in which the working feeding track 11 extends. Inside enclosure 1; as in figure 2 As shown, the dispensing device 20 includes at least one three-axis manipulator and at least one dispensing mechanism 21, each dispensing mechanism is respectively fixed on the action execution end of each three-axis manipulator, and each three-axis manipulator can drive each point respectively. The glue mechanism performs a three-dimensional displacement action, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com