Punching machine with infrared alarming function

An infrared alarm and punching technology, which is applied in metal processing equipment, safety equipment, manufacturing tools, etc., can solve the problems of high punching pressure, physical injury of operators, and no protective measures, etc., and achieve the effect of preventing danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

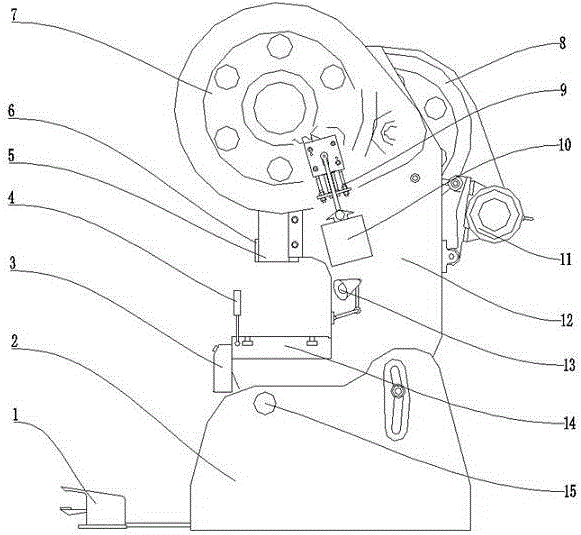

[0014] The present invention will be further explained below in conjunction with the drawings:

[0015] Such as figure 1 As shown, an infrared alarm punch press includes a base 2 and a body 12. A pedal 1 is provided next to the base 2. The pedal 1 is used to control the stamping process, and the side of the base 2 is provided with a warning light 15 which is used for danger alarm , The base 2 is provided with a fuselage 12, a workbench 14 is set on the front of the fuselage 12, and the workbench 14 is used to place stamping materials. A control box 3 is set next to the workbench 14, and the control box 3 is used to control the operation of the machine. 3 is provided with a handle 5 next to it, which is used to control the clamping material, a lighting lamp 13 is set next to the workbench 14, and the lighting lamp 13 is used to fill light, a motor 11 is set behind the body 12, and a pulley 8 is set next to the motor 11 An eccentric wheel 7 is arranged beside the pulley 8, a trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com