Bottle opener

A bottle opener and sliding switch technology, applied in the field of bottle openers, can solve the problems of user injury, cracking, and failure to recycle, and achieve the effects of reducing the probability of damage, ensuring body safety, and ensuring reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

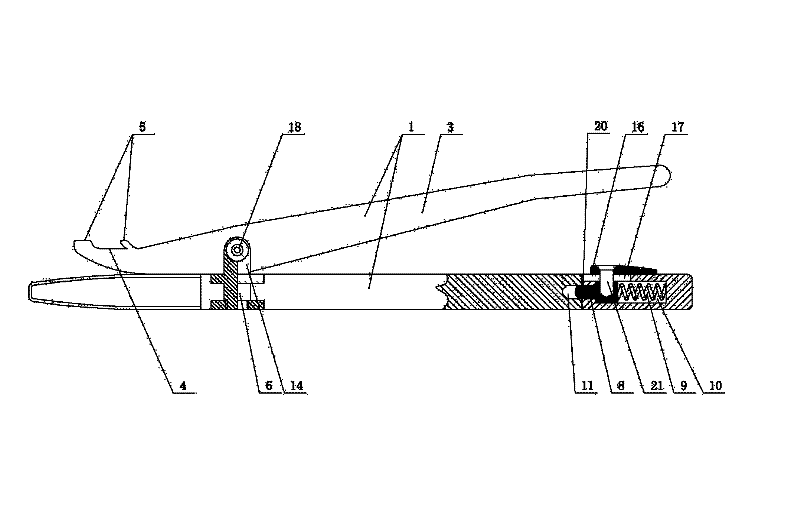

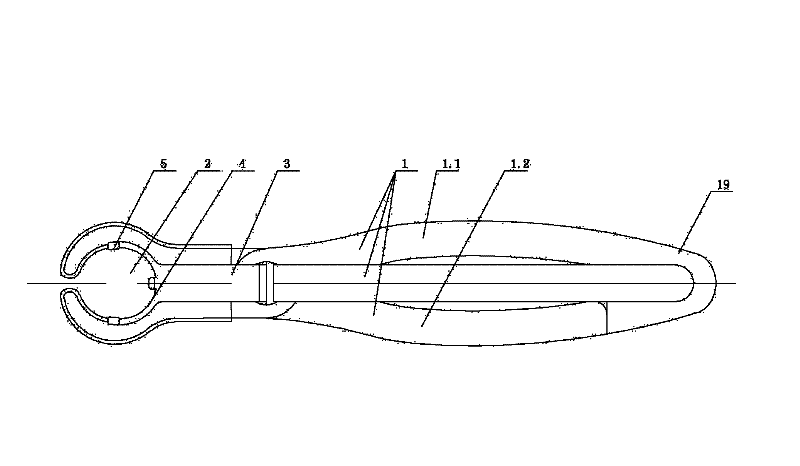

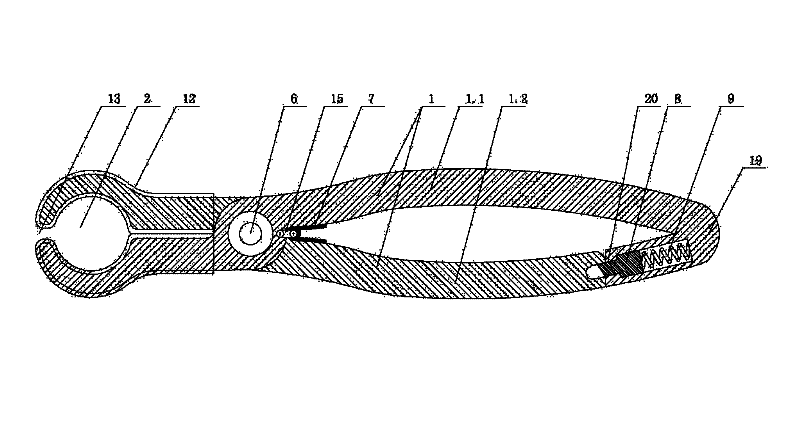

[0020] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a bottle opener of the present invention includes a body 1, and the front part of the body 1 is provided with a through hole 2 for the bottle mouth to be embedded. There is an opening 13 to facilitate clamping the bottle.

[0021] A lever-type operating handle 3 is hinged on the body 1 at the rear of the through hole 2, and the axis of the first hinge shaft 18 of the operating handle 3 and the body 1 is perpendicular to the axis of the through hole 2; The specific structure is: the first hinged shaft 18 is fixed on the fixed frame 14, and the bottom of the fixed frame 14 is connected with the second hinged shaft 6 as a whole, so that the axis of the through hole 2 is parallel to the axis of the second hinged shaft 6, and the second The axis of the hinge shaft 6 perpendicu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com