Bright oxygen-free copper flat profile crystallizer

A crystallizer and oxygen-free copper technology, applied in the field of bright oxygen-free copper flat section crystallizers, can solve problems such as ingot quality defects, large cooling water consumption, increased energy consumption of metal casting, etc., to reduce hot spots or local Excessive temperature gradient, less damage to mechanical strength and rigidity, and effects of avoiding insufficient sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

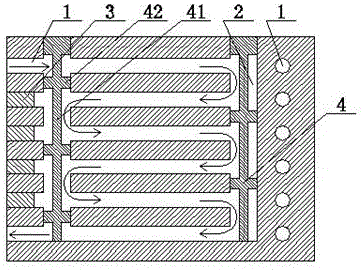

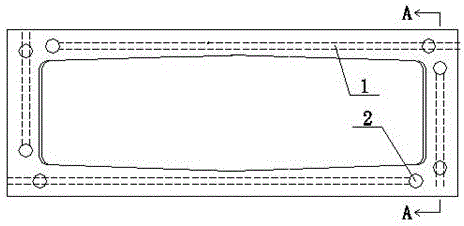

[0015] refer to Figure 1 to Figure 2 , Figure 1 to Figure 2 It is a structural schematic diagram of a specific embodiment of the present invention.

[0016] Such as figure 1 and figure 2 As shown, a bright oxygen-free copper flat profile crystallizer includes a rigid crystallizer body of good heat-conducting material, the crystallizer body includes a plurality of side walls, a plurality of side walls surround a crystallization channel, each The side walls are provided with cooling passages; the cooling passages include a plurality of horizontal cooling passages 1 and two vertical cooling passages 2, the horizontal cooling passages 1 and the vertical cooling passages 2 are blind holes, and A plurality of the horizontal cooling passages 1 are coplanar with the two vertical cooling passages 2; The vertical through-hole plug 4 of the straight cooling passage 2, the vertical through-hole plug 4 includes a fixed connection post 41 and a through-hole sealing plug 42 arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com