360-degree rotation pneumatic full-automatic positioning and clamping device for flat knife support

A positioning and clamping, fully automatic technology, applied in the field of clamping tools, can solve problems such as difficulty in stable clamping positioning, poor clamping stability, increase clamping error, etc., to achieve uniform pressing force, avoid workpiece deformation, The effect of avoiding clamping errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

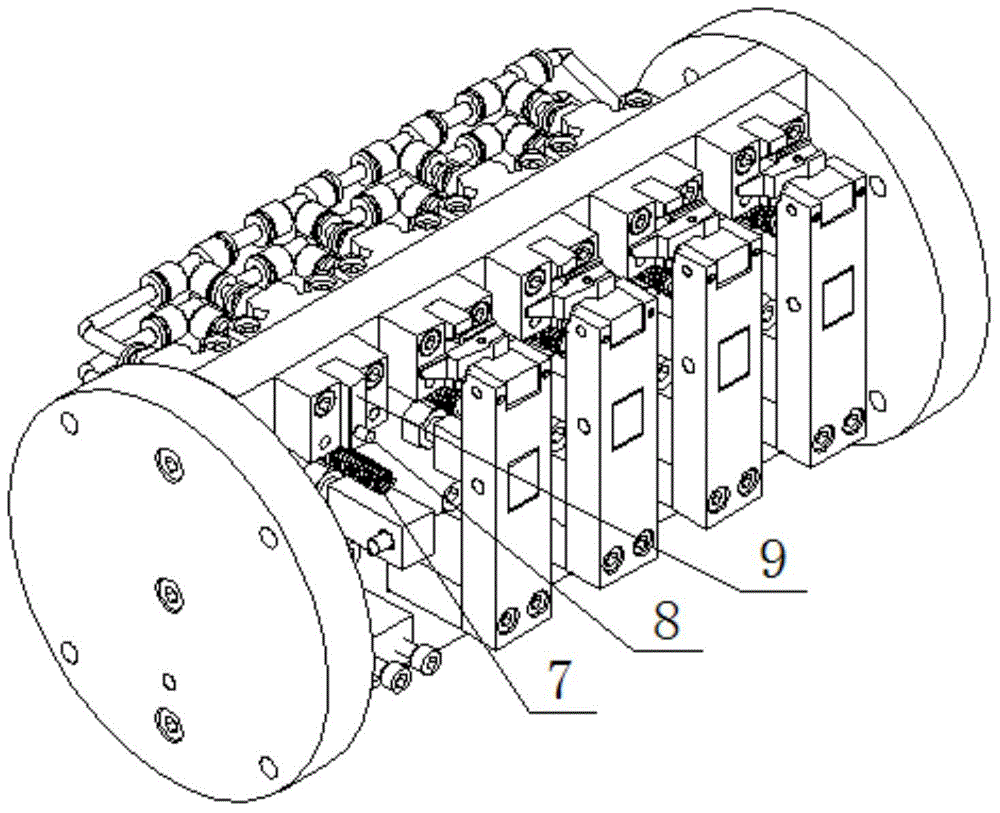

[0019] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

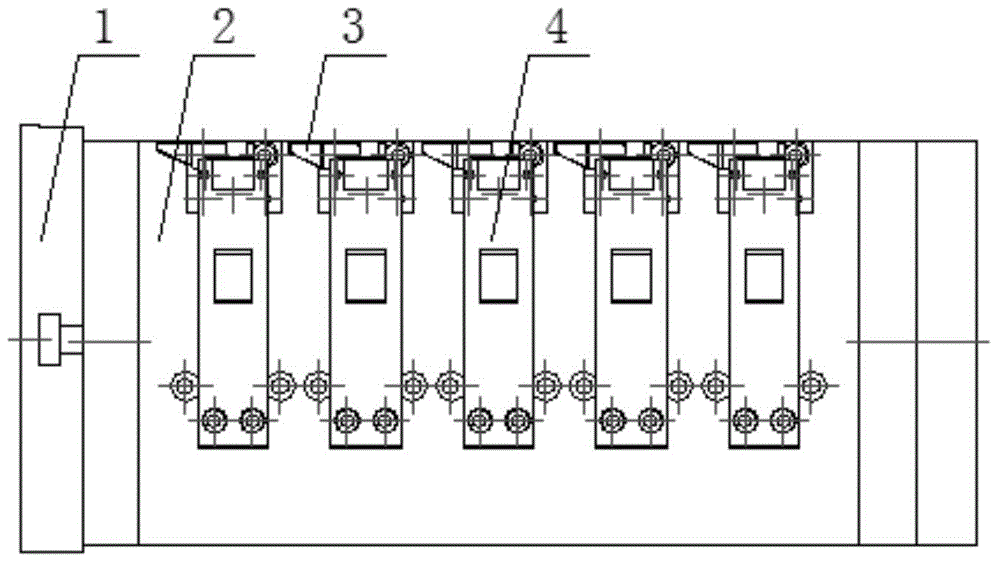

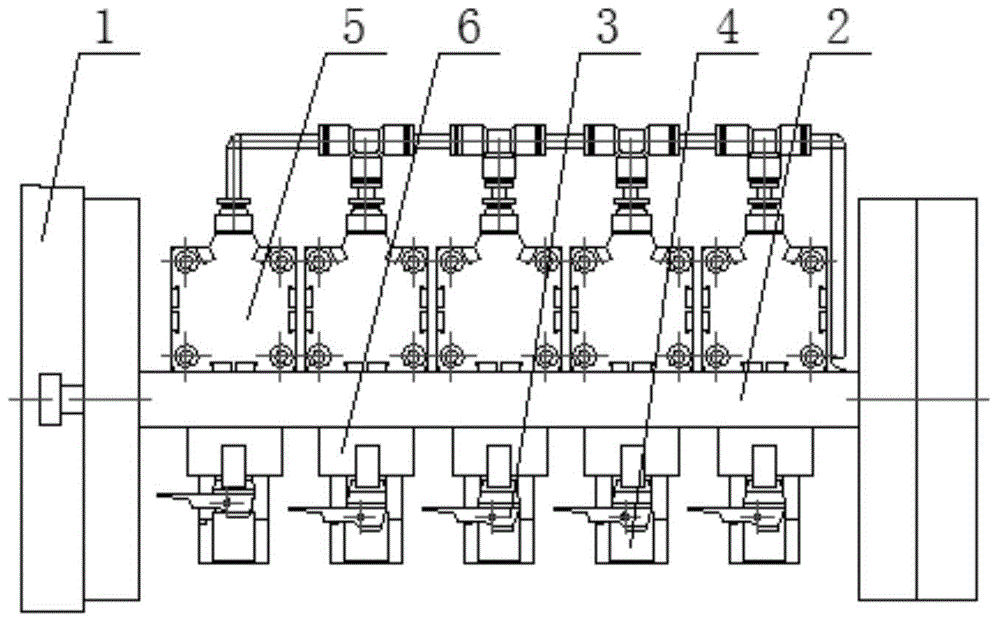

[0020] A flat knife supporting 360° rotating pneumatic automatic positioning and clamping equipment, including a main board 2, a four-axis connecting plate 1, a compression cylinder 5, a pressing plate 4 and a slot positioning block 6, and a four-axis connecting plate is installed on the left and right ends of the main board. board, the two four-axis connecting boards are arranged coaxially.

[0021] A plurality of compression cylinders are evenly distributed on the back side of the main board, and the compression cylinders are arranged side by side and the number is not limited. The piston rod of each compression cylinder is all arranged vertically downwards, and the lower end of each piston rod is connected wi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap