High-speed stamp machine

A stamping machine, high-speed technology, applied in the field of stamping, can solve the problems of time-consuming and laborious stamping, unable to realize fully automatic operation, etc., and achieve the effect of convenient installation and debugging, high-speed and accurate position stamping, and stable transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

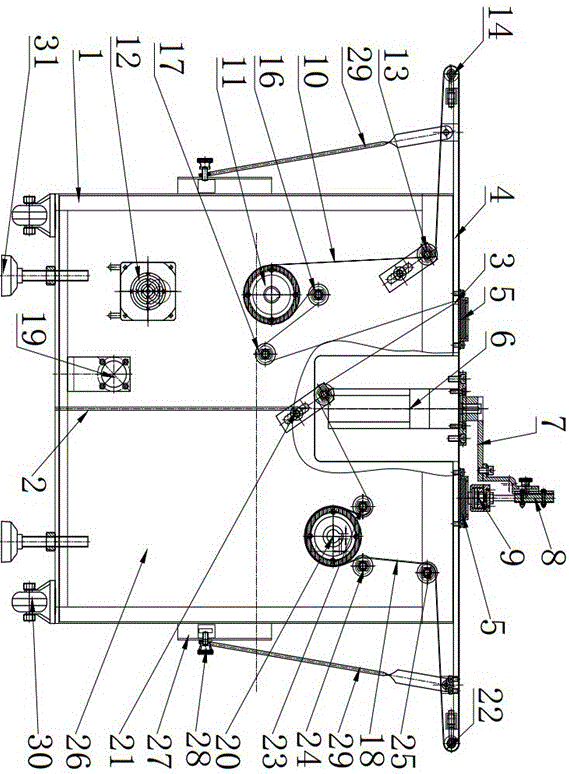

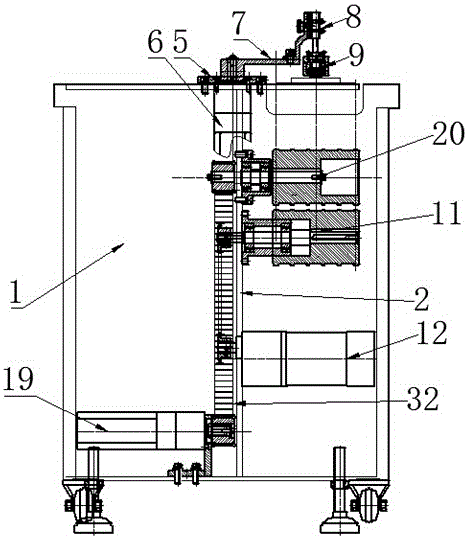

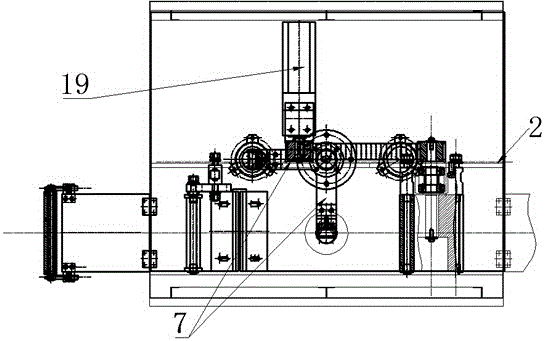

[0025] The present invention will be further described below in conjunction with accompanying drawing:

[0026] A high-speed stamp machine, comprising a box body 1, a partition plate 2 is arranged inside the box body 1, a workbench 4 with a through hole 3 is arranged on the upper surface of the box body 1, a pulping box 5 is arranged on the workbench 4, and the box body 1 is provided with a feeding system, a rotary stamping system and a discharge system; the rotary stamping system includes a second servo motor 6 arranged inside the box body 1, and the rotating shaft of the second servo motor 6 passes through the workbench 4. The upper surface is connected to two mutually perpendicular stamp frames 7, and the other end of the stamp frame 7 is fixedly connected to the cylinder 8, and the cylinder rod is provided with a stamp mechanism 9.

[0027] In order to realize automatic feeding, the feeding system includes a feeding conveyor belt transmission structure, and the feeding con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com