Back door material rack

A technology on material racks and brackets, which is applied in the field of back door material racks, can solve problems such as unsatisfactory clamping effect of the back door, friction and collision of the back door, etc., achieve good fixing effect, avoid friction and collision, and have reasonable structure settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

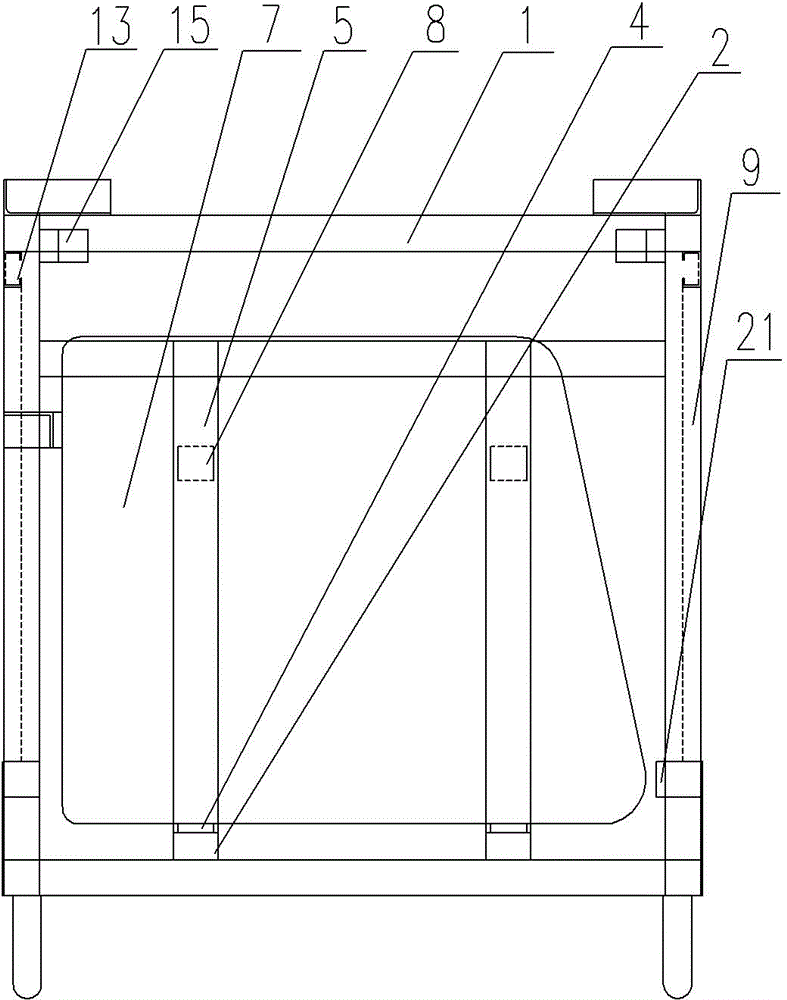

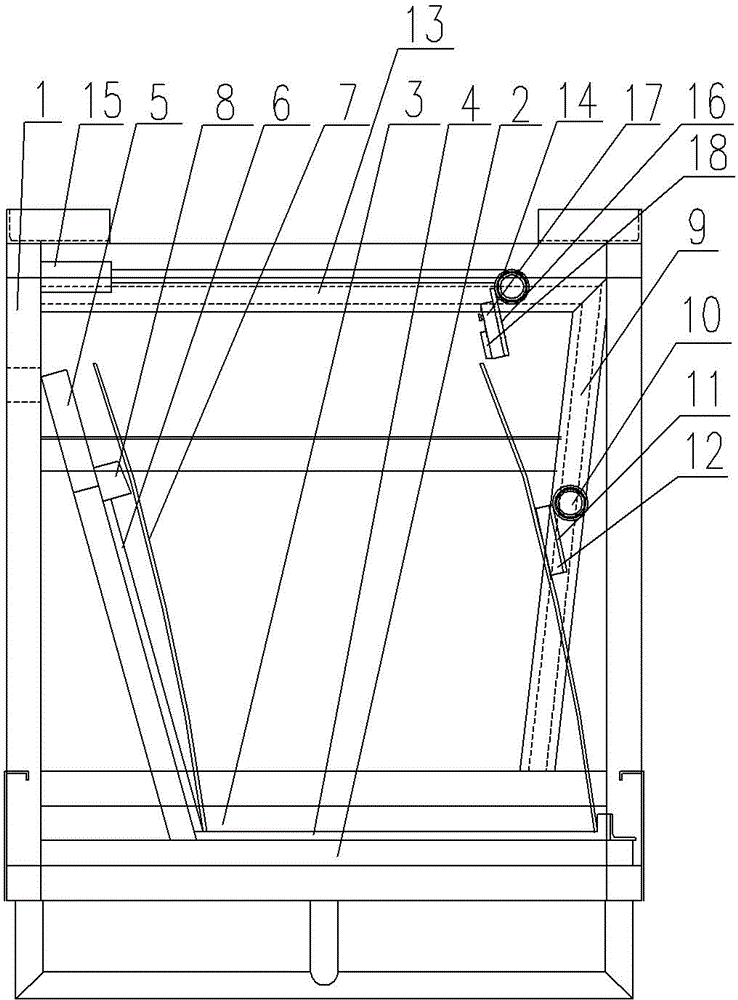

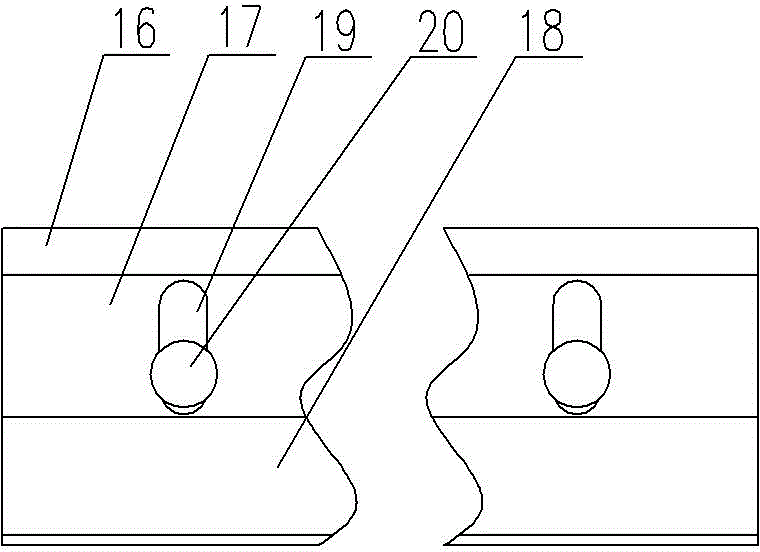

[0013] See figure 1 , figure 2 , image 3 As shown, a back door material rack includes a bracket 1, two bottom support bars 2 arranged in parallel are installed on the bracket 1, and a placement groove 3 is opened on the bottom support bar 2, and a bottom rubber strip 4 is installed in the placement slot 3, One end of the bottom support bar 2 is installed with an obliquely arranged side support bar 5, and the side rubber bar 6 is installed on the side support bar 5. The lower end of the side rubber bar 6 is in contact with the bottom rubber bar 4 to ensure that the back door 7 is always in contact with the rubber bar. , to avoid friction and collision caused by direct contact with the bracket 1, a plastic cushion 8 is installed on the side support bar 5 at the upper end of the side rubber strip 6, and a side chute 9 is respectively installed on both sides of the bracket 1 at the other end of the bottom support bar 2, and the side chute 9 is installed on the side A slidable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com