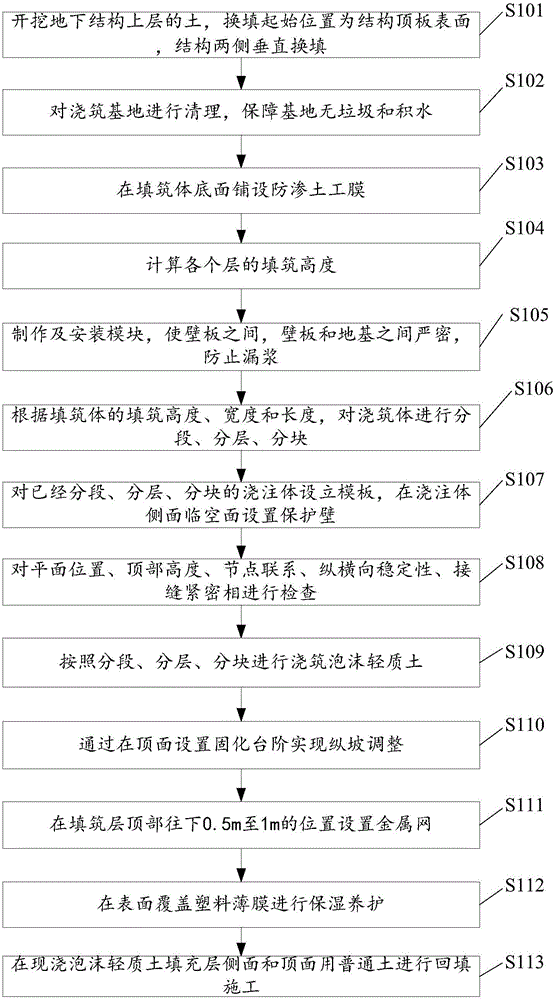

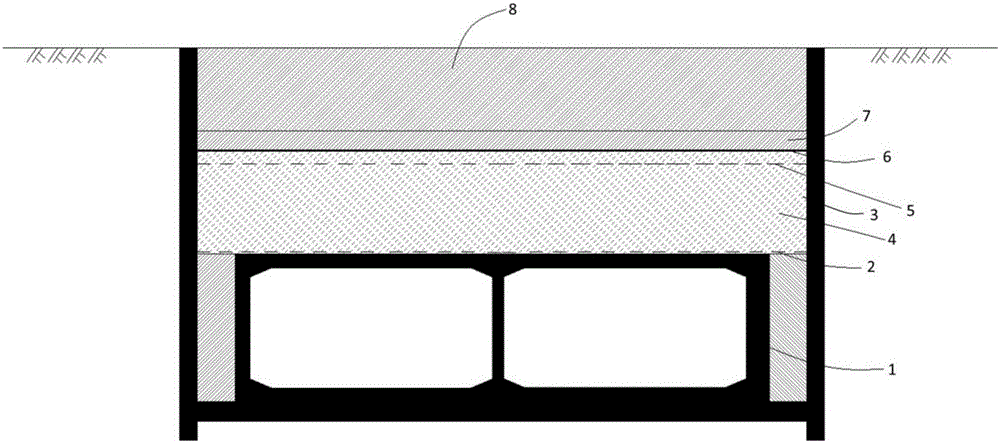

Underground structure construction method based on cast-in-place foam lightweight materials

A foam lightweight material and underground structure technology, applied in infrastructure engineering, underwater structures, artificial islands, etc., to achieve obvious technical and economic advantages, strong self-reliance, and small bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] 1. Before construction, the soil on the upper layer of the underground tunnel structure shall be excavated, the starting position of replacement shall be the surface of the roof of the structure, and the replacement shall be performed vertically on both sides of the structure.

[0070] 2. Clean up the pouring base. The principle of cleaning is that there is no garbage or water on the base, and no obvious dust should be left as far as possible to ensure that there is no clear water on the base.

[0071] 3. Lay polyethylene anti-seepage geomembrane on the bottom of the filling body.

[0072] 4. Cast-in-place foam lightweight soil is selected as the backfill material for load reduction, and the maximum replacement height is 3m.

[0073] 5. To make and install the formwork, it is required that the wall panels and between the wall panels and the foundation should be tight to prevent grout leakage.

[0074] 6. According to the height, width and length of the filling body, se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com