Midway well used for pipe-jacking pipeline

A pipeline and pipe jacking technology, which is applied in the field of midway wells, can solve the problems of long construction period, high construction risk, and difficult construction of pipe jacking midway wells, and achieve the effects of shortening the construction period, improving construction safety, and reducing construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

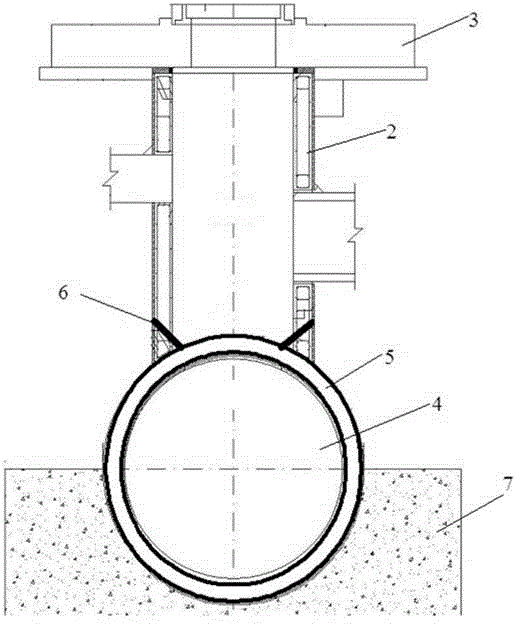

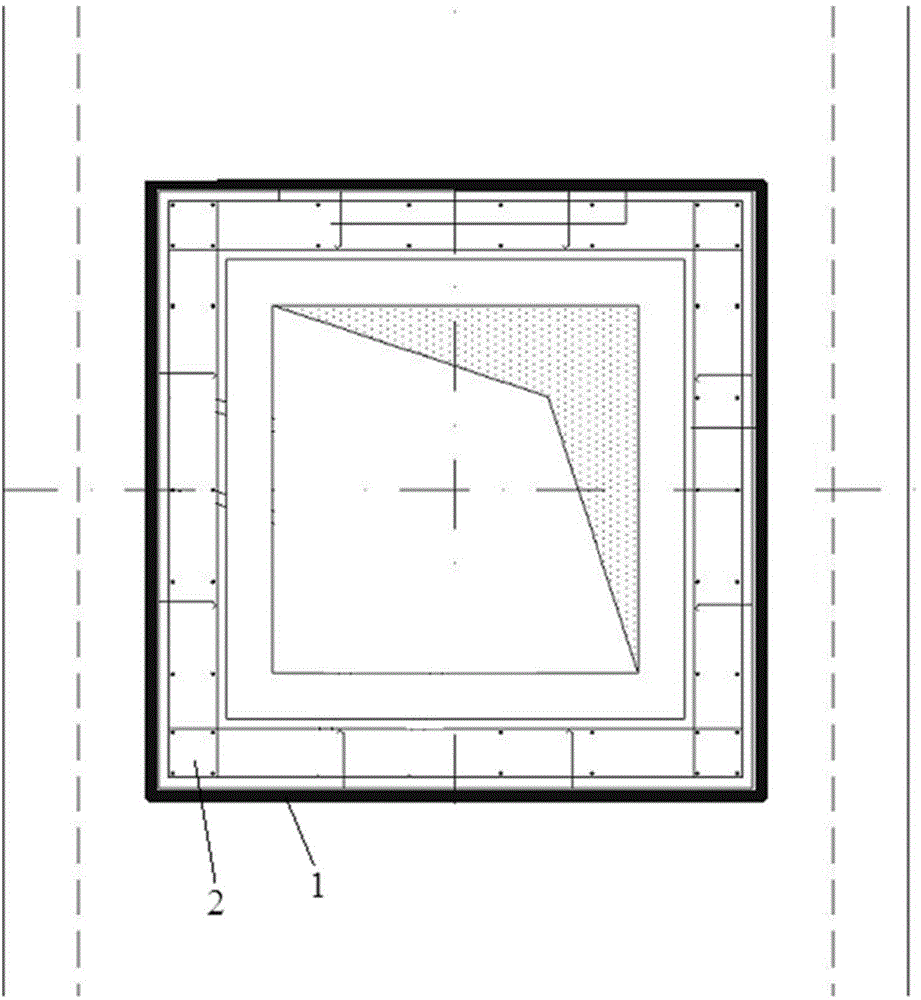

[0020] Such as figure 1 and 2 As shown, a midway well for pipe jacking is connected with the pipe jacking pipeline 4. The midway well includes a steel plate enclosure 1, a cover plate 3 and an outsourcing steel plate 5. There are 5 sets of outsourcing steel plates On the pipe jacking pipe 4, the upper end of the steel plate enclosure 1 is connected with the cover plate 3, and the lower end is connected with the outer steel plate 5 through the inclined rib plate 6, forming a closed system.

[0021] The steel plate enclosure 1 has a square structure, which is directly driven in by a piling machine after welding, and is double-liquid grouted around the steel plate enclosure. The lower part and both sides of the jacking pipe at the connection with the steel plate enclosure adopt compaction grouting7.

[0022] The cover plate 3 adopts a large reinforced concrete cover plate. The diagonal rib 6 and the steel plate enclosure 1 are arranged at 45°. After the closed system is forme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com