Shallow-earthing, large-section and small-distance construction method for rectangular pipe jacking overpass subway tunnel

A technology of rectangular pipe jacking and tunnel construction, which is used in tunnels, tunnel linings, earth drilling and mining, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further elaborated and illustrated below in conjunction with the accompanying drawings and embodiments. The technical features of the various implementations in the present invention can be combined accordingly on the premise that there is no conflict with each other.

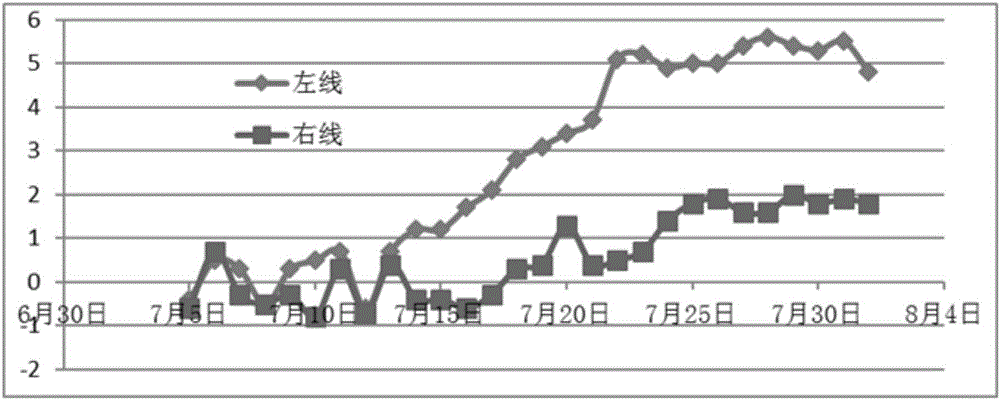

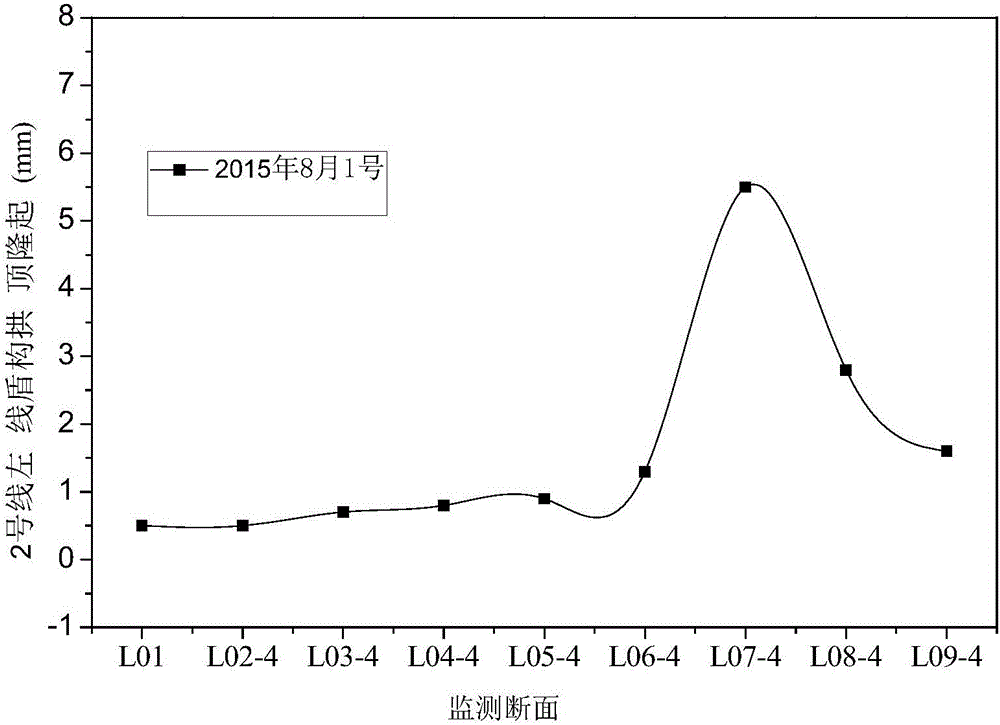

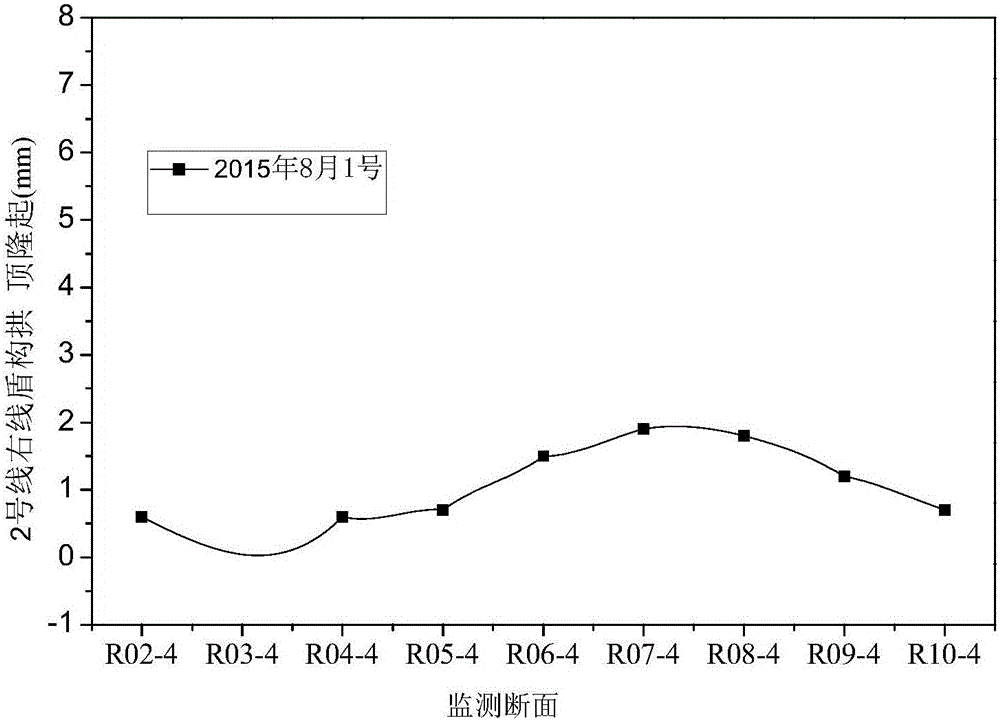

[0045]The following takes a subway tunnel pipe jacking construction project as an example. Its working conditions are as follows: the pipe jacking passage of the left and right lines of the existing Metro Line 2 in operation above is perpendicular to the tunnel of Shenzhen Metro Line 2 below. The length of the rectangular pipe jacking in this section is 41m, and it is composed of 3 parallel pipe jacking channels with a total of 123m. The net distance between the channels is 2.15m, which belongs to the small-pitch jacking, which will affect the formed channels during the jacking process. The minimum distance between the outer wall of the pipe jacking and the ground surface i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com