Non-linear formula correction method for leather dyeing and color matching

A non-linear correction and formulation technology, applied in color matching, color measurement devices, special data processing applications, etc., can solve the problems of large differences in leather raw materials, great influence on the color of dyed leather, poor applicability, etc., and achieve the improvement of automation level , improve proofing efficiency, and the effect of huge economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with specific embodiment, the present invention is further elaborated.

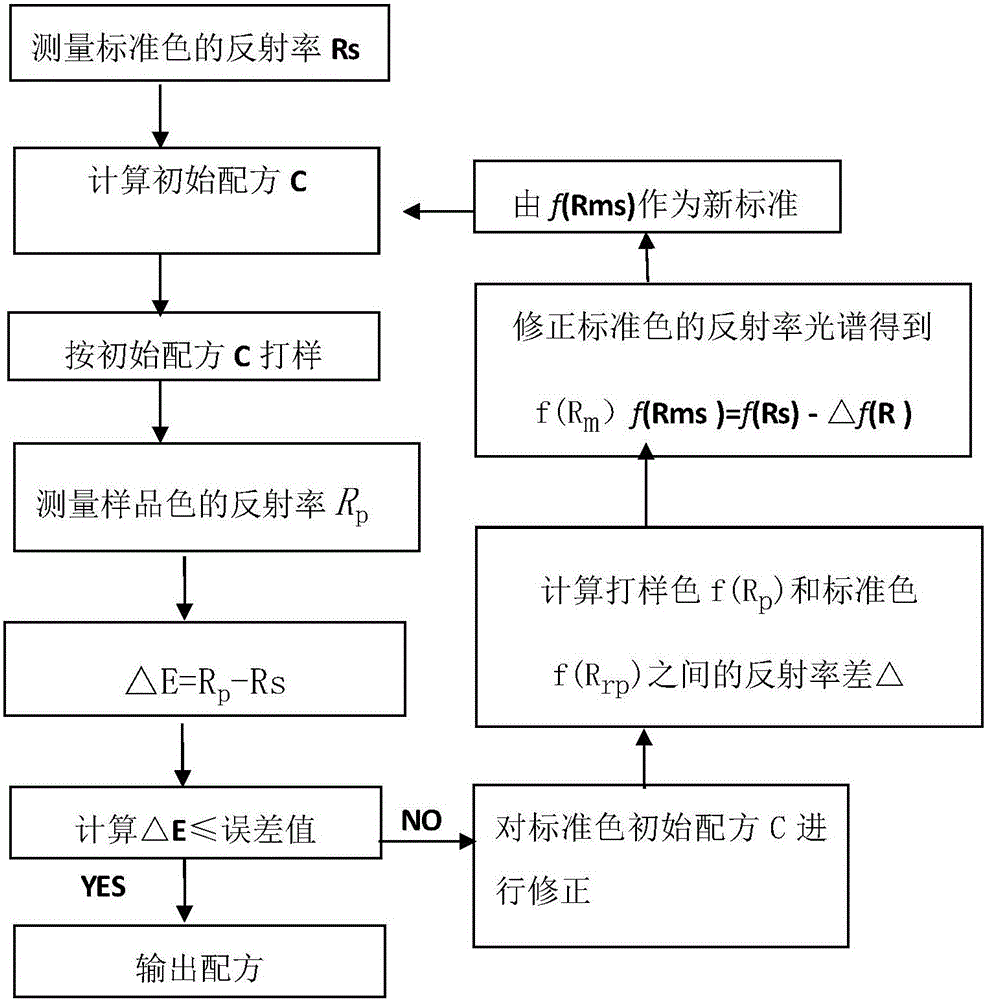

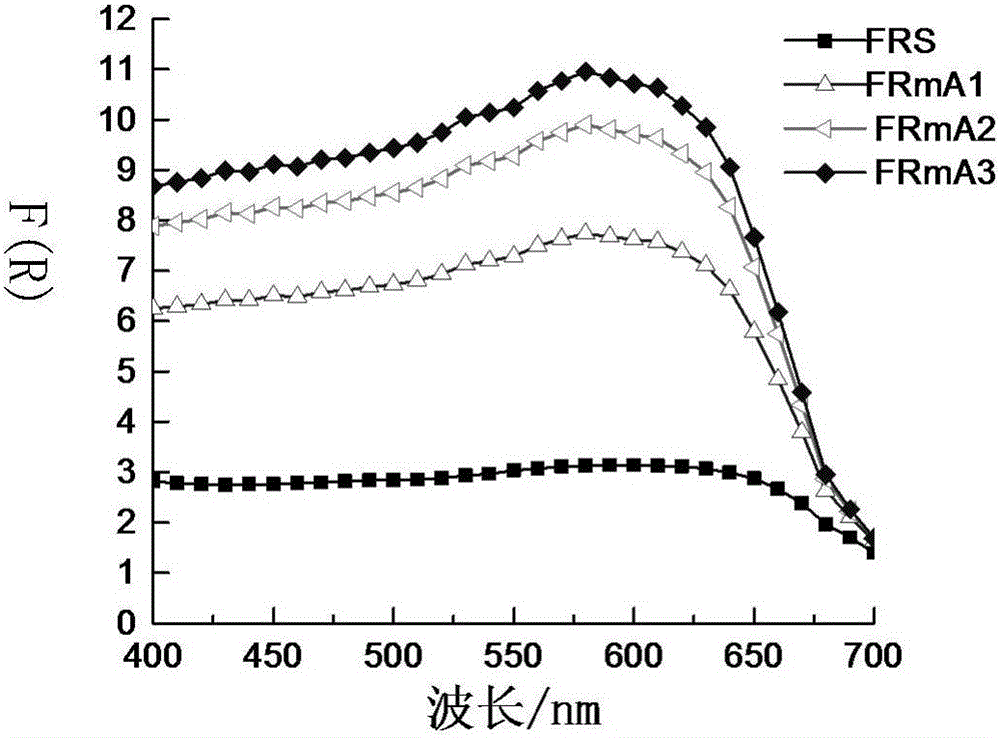

[0033] see Figure 1 to Figure 5 , a kind of non-linear formula correcting method for leather dyeing and color matching of the present invention is applicable to the color matching of top layer leather dyeing, comprises the steps:

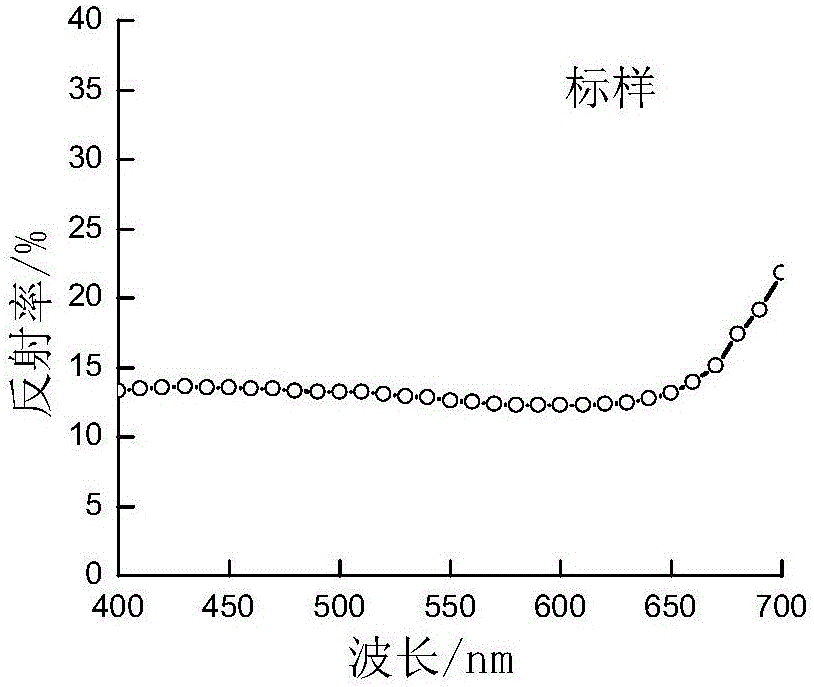

[0034] a. Based on the standard color, use computer software to measure the initial formula C of the standard color, and carry out dyeing and proofing according to the initial formula C=[c1,c2,c3]T to obtain a sample color, and use a spectrophotometer to measure the primary color sample color, and compare the color difference with the reflectance of the standard color; the measurement uses a datacolor600 colorimeter, with a 10° field of view, the measurement aperture is 30mm, and the specular reflection is included; 3 different positions of the sample are measured to obtain the average reflectance Rp , and measure the reflectance Rs of the standard...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com