Light guide plate and light source module

A light source module and light guide plate technology, which is applied in light guides, optics, optical components, etc., can solve problems affecting the uniformity of the surface light source, affecting the distribution of light patterns of the surface light source, and affecting the optical quality of the light source module, so as to reduce scratches on the bottom surface or Chance of rubbing, good optical quality, effect of reducing generation of bright spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The aforementioned and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of multiple embodiments with accompanying drawings. The directional terms mentioned in the following embodiments, such as up, down, front, back, left, right, etc., are only directions referring to the drawings. Accordingly, the directional terms are used to illustrate, not to limit, the invention.

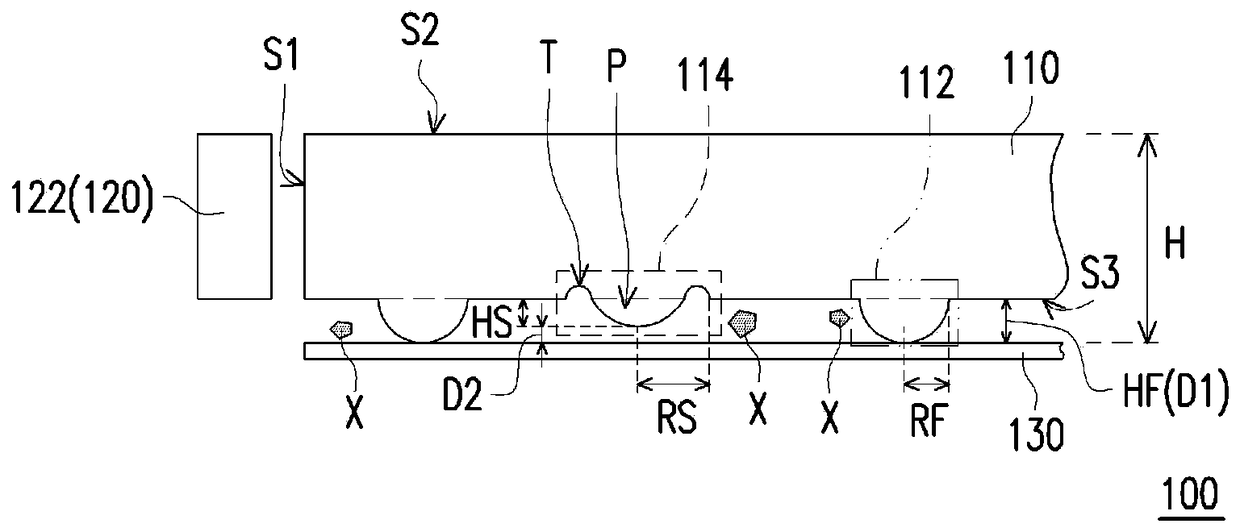

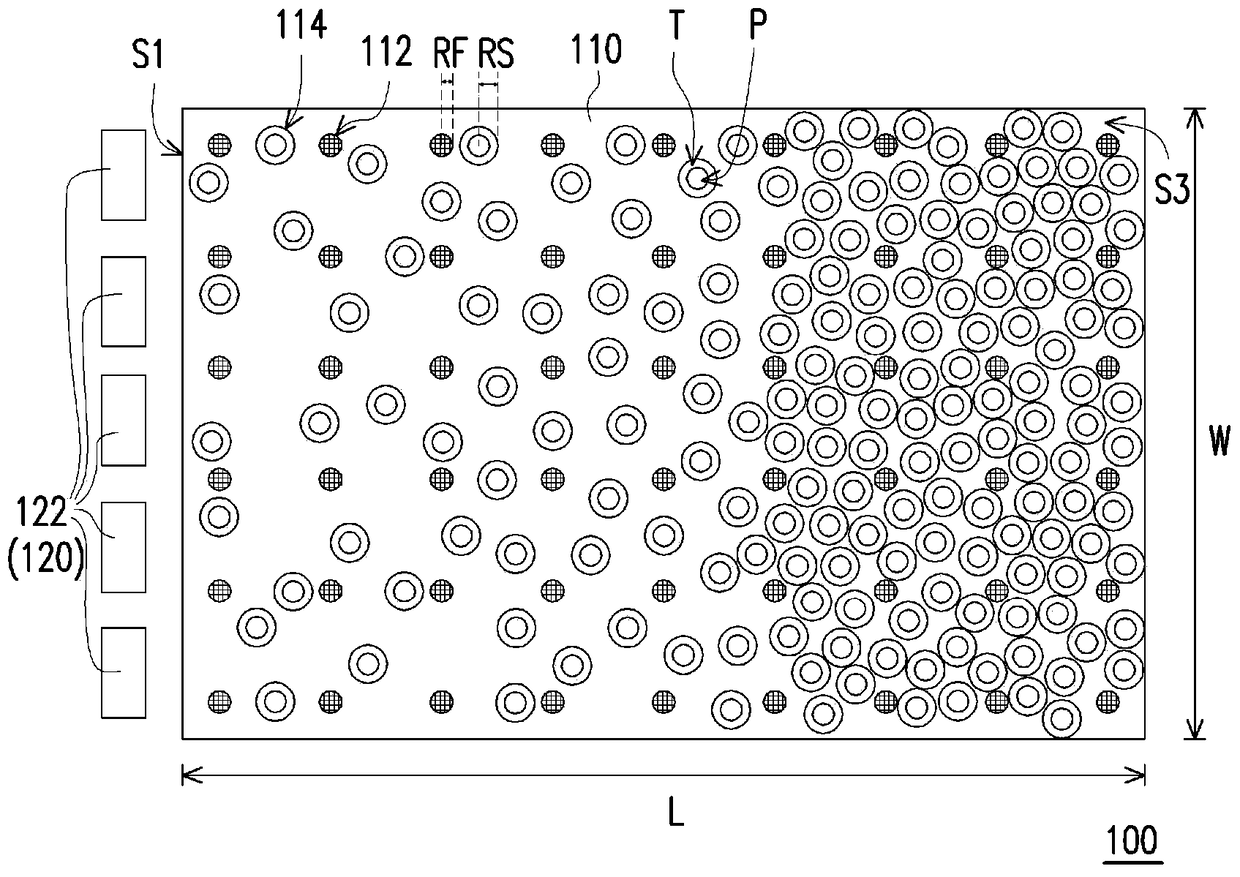

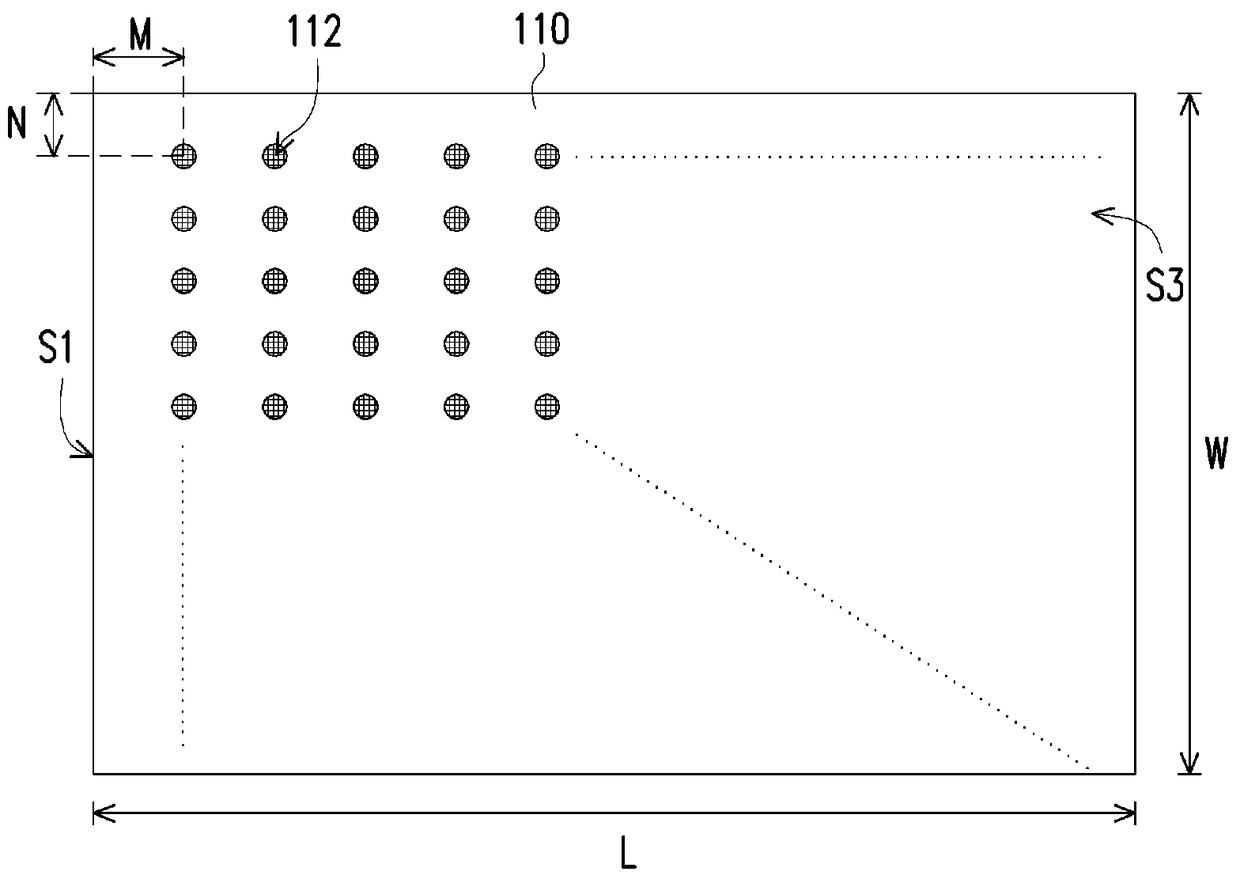

[0029] Figure 1A is a partial cross-sectional schematic diagram of a light source module according to an embodiment of the present invention. Figure 1B It is a schematic bottom view of a light source module according to an embodiment of the present invention. In order to clearly indicate the first outlet and the second outlet, Figure 1B omitted from Figure 1A reflective sheet. Please refer to Figure 1A and Figure 1B , the light source module 100 of this embodiment includes a light guide plate 110 and a light ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com