A Frequency Domain Fatigue Analysis Method for Vehicle Suspension Leaf Springs

A technology for leaf spring and fatigue analysis, applied in the direction of instrument, design optimization/simulation, calculation, etc., can solve the problems of long development cycle and high test cost, and achieve the effect of high result accuracy, shortened design cycle, and small amount of calculation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

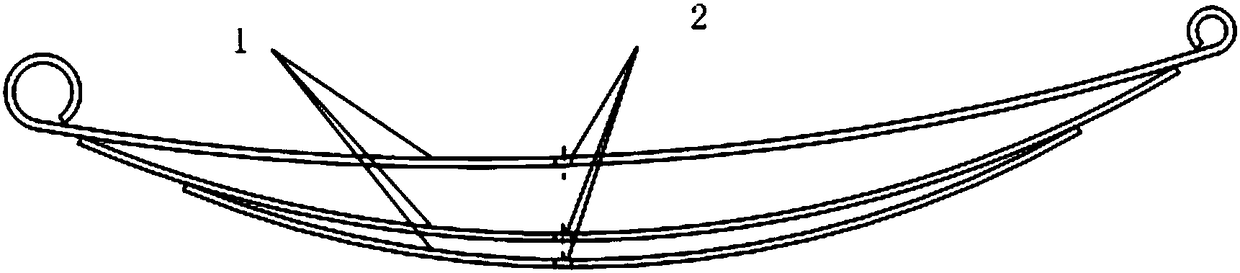

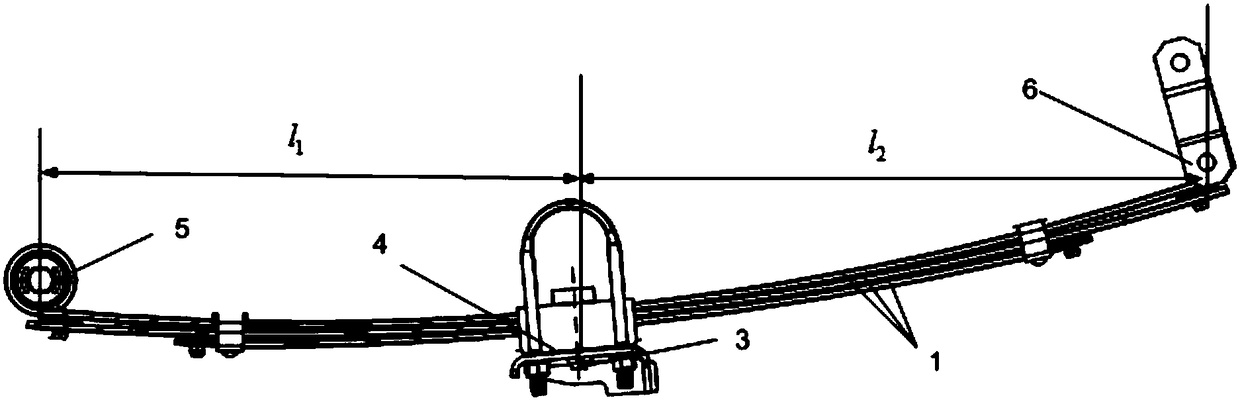

[0031] In the frequency domain fatigue analysis method of vehicle suspension leaf springs in this embodiment, the leaf springs are used in automobile suspensions, and several reeds with different curvatures are clamped by bolts and leaf spring seats to form elastic elements, such as figure 1 and figure 2 As shown, there are three reeds 1 in this embodiment, and a bolt hole 2 is arranged at the center of each reed; the leaf spring has three states, which are respectively free state, assembled state and working state; figure 1 Each reed 1 is in a free state in the leaf spring of the shown free state; figure 2 The assembly state shown refers to the clamping of the bolt 3 and the leaf spring seat 4 on the basis of the free state, such as figure 2 As shown, each reed is assembled into an integral component with the same curvature, and prestress is formed on the reed; the leaf spring under working condition, its leaf spring seat 4 is fixedly connected with the rear axle of the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com