Split conductor fixing structure

A split wire and fixed structure technology, which is applied in the installation of electrical components, cables, overhead installation, etc., can solve the problems that the split wire cannot adapt to various types, and the test efficiency of the split wire is low, so as to prevent the disc from being separated and have a simple structure , the test effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

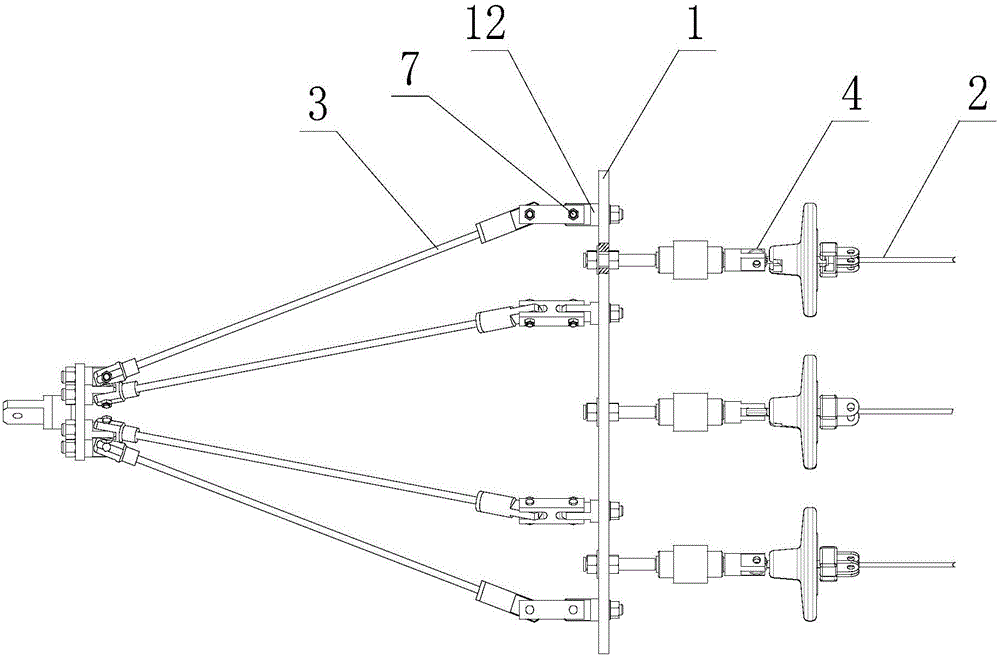

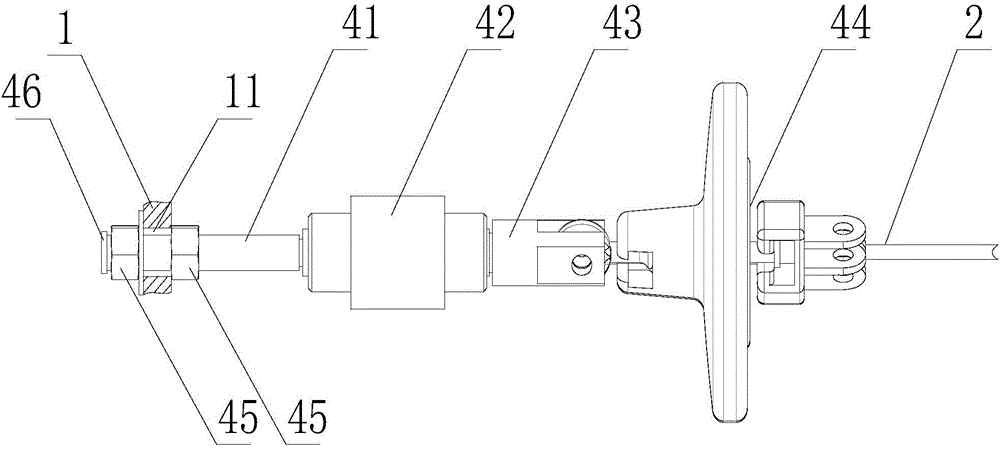

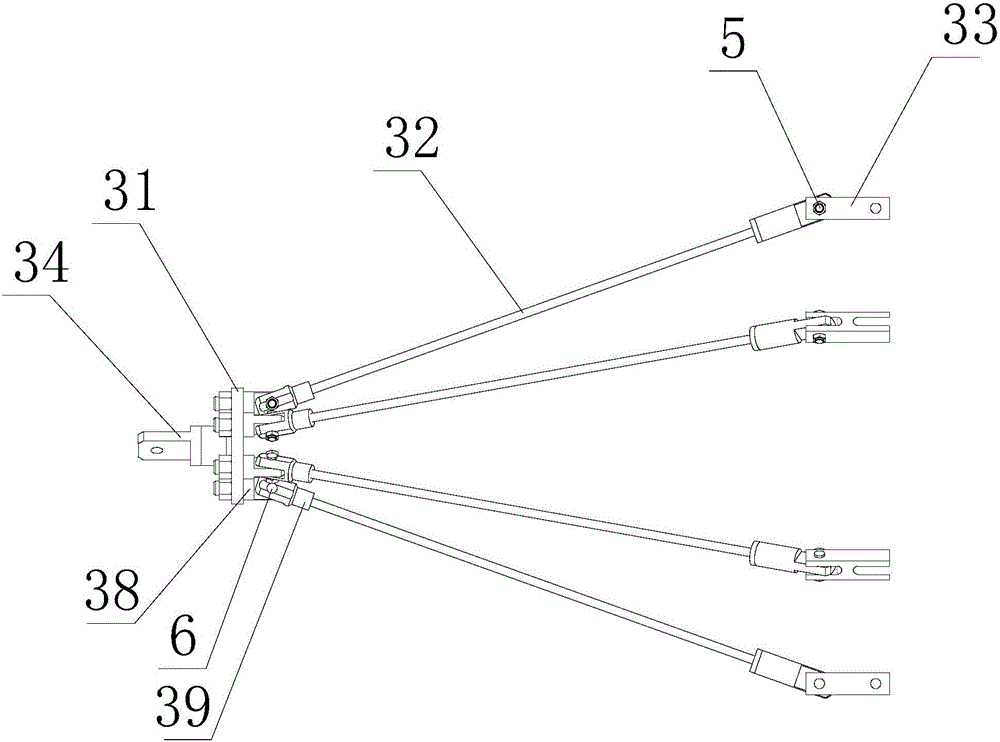

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the split wire fixing structure includes a disk 1 connected with a split wire 2, a multi-split puller device 3 is connected to the disk 1, and several groups of circular holes 11 for fixing the split wire 2 are arranged on the disk 1. The hole 11 is set according to different types of split wires. The round hole 11 is connected with a connector 4 connected to the split wire 2. The connector 4 passes through the round hole 11 and is fixed on the disc 1. The connector 4 includes a transition sleeve 41, The tension sensor 42, the connection sleeve 43 and the insulator assembly 44, the tension sensor 42 is arranged between the transition sleeve 41 and the connection sleeve 43, the connection sleeve 43 is connected with the insulator assembly 44, the transition sleeve 41 passes through the round hole 11 and passes through the nut 45 It is fixedly connected to the disk 1, and the split wire 2 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com