Battery set, automatic capacity calibration learning method for battery set and automatic capacity calibration learning system

An automatic calibration, battery pack technology, applied in battery circuit devices, electric vehicles, measurement of electrical variables, etc., can solve problems such as increasing the discharge current resting time, battery calibration accuracy, etc., to improve utilization and benefit costs control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

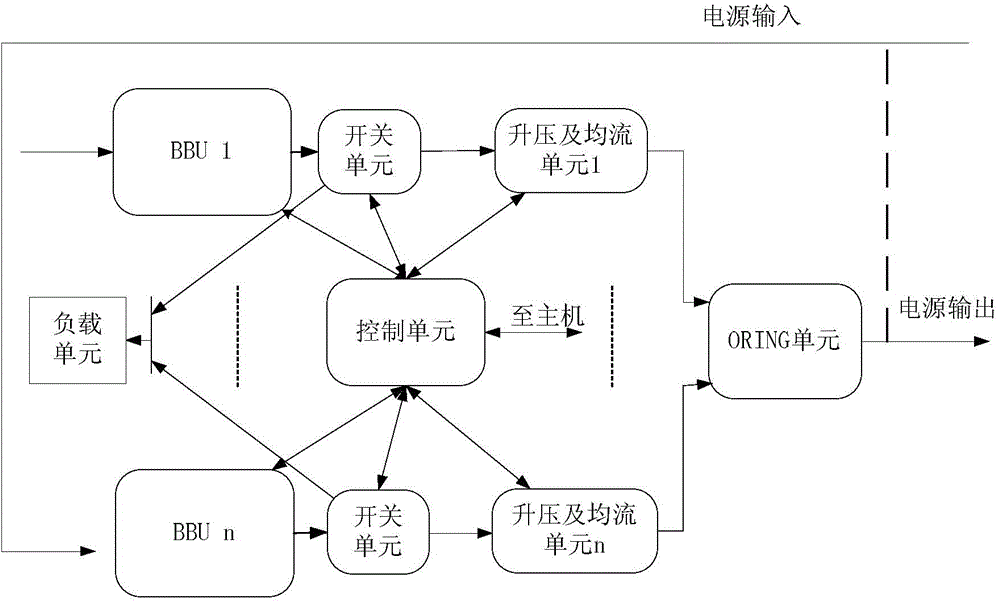

[0042] This embodiment 1 provides a new battery pack and battery pack system for the problem that the battery pack capacity automatic calibration learning must stop the system business, please refer to figure 1 , the battery pack includes multiple parallel branches and ORING units, where:

[0043] Each parallel branch of the plurality of parallel branches includes:

[0044] A backup battery unit BBU, the input end of which is connected to the power input end of the battery pack;

[0045] A boost and current share unit, the input of which is connected to the output of the BBU in the same parallel branch;

[0046] The input end of the ORING unit is connected to the output ends of the boosting and current sharing units in the plurality of parallel branches, and the output end is used as the power output end of the battery pack.

[0047] The number of BBUs included in a battery pack can be selected and adapted according to the system's requirements for power and output current. ...

Embodiment 2

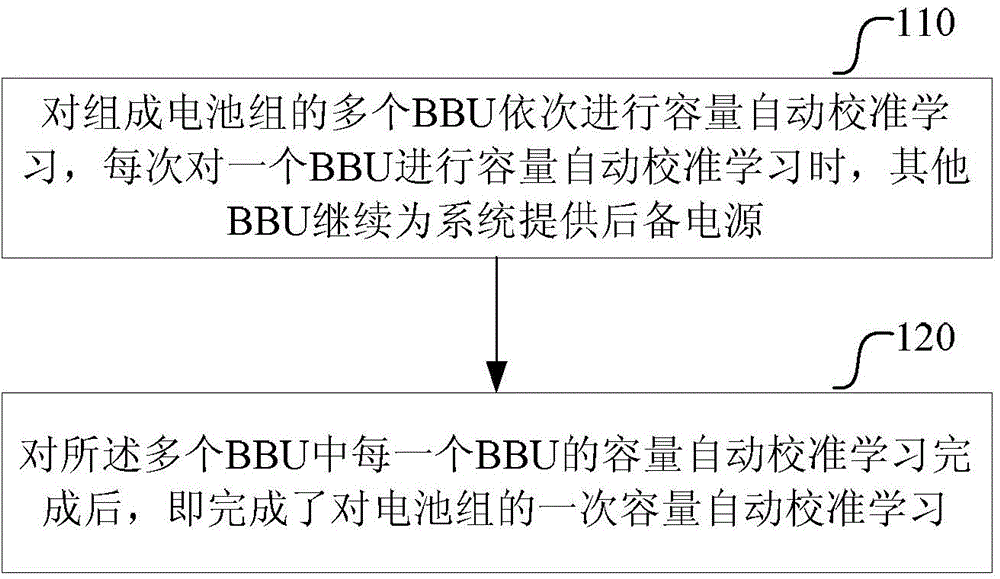

[0061] This embodiment provides a method for automatically calibrating and learning the capacity of a battery pack, which can be applied to the battery pack system in Embodiment 1, wherein the battery pack includes a plurality of backup battery units BBU, which together provide backup power for the system, such as figure 2 As shown, the method includes:

[0062] Step 110, performing automatic capacity calibration learning on the multiple BBUs in sequence, and each time automatic capacity calibration learning is performed on one BBU, other BBUs continue to provide backup power for the system;

[0063] In this embodiment, preferably, before each BBU is automatically calibrated to learn the capacity, the working status of all BBUs is detected, such as the battery pack composed of other BBUs except this BBU can meet the system’s requirements for backup power such as Meet the requirements for capacity and current, and then conduct capacity automatic calibration learning for the BB...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com