Electric vehicle traction motor design parameter verification method

A technology for traction motors and electric vehicles, applied in electric vehicles, manufacturing motor generators, motors, etc., can solve the problems of difficult to reflect the characteristics of the typical motion conditions of the whole vehicle, cumbersome calibration steps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A method for verifying design parameters of electric vehicle traction motors is characterized in that: it is implemented according to the following steps:

[0048] (1) Set the uniform motion calculation module and acceleration motion calculation module based on Matlab / Simulink:

[0049] In this embodiment, both the uniform motion calculation module and the accelerated motion calculation module use digital signal controllers;

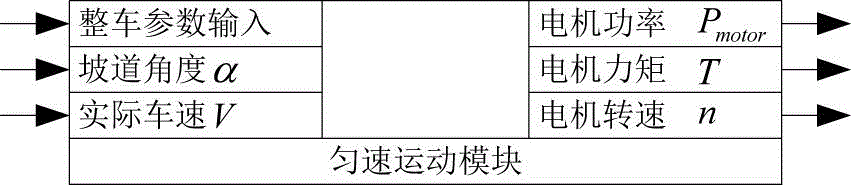

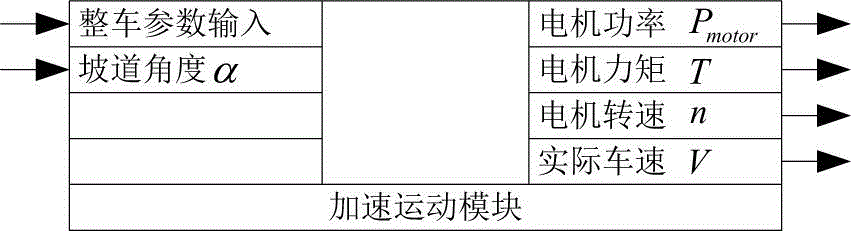

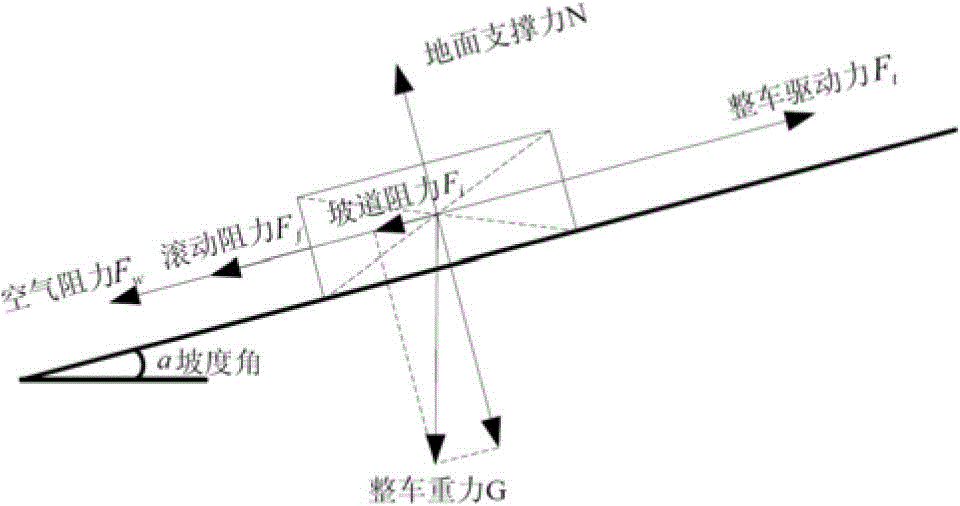

[0050] The functions of the uniform motion calculation module are as follows: figure 1 As shown, the input of the uniform motion calculation module is the vehicle parameters, actual vehicle speed, ramp angle and other information; Calculate the traction power of the whole vehicle, indirectly calculate the power of the traction motor through conversion efficiency conversion, calculate the motor speed corresponding to the current speed according to the relationship between the vehicle speed and the motor speed, and calculate the torque of the tract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com