Vibration engine based on force-sensitive elastomer material

An elastomer material and elastomer technology, applied in the field of physics, can solve the problems of complex structure, large volume and poor reliability of generators, and achieve the effects of simple structure, small volume and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

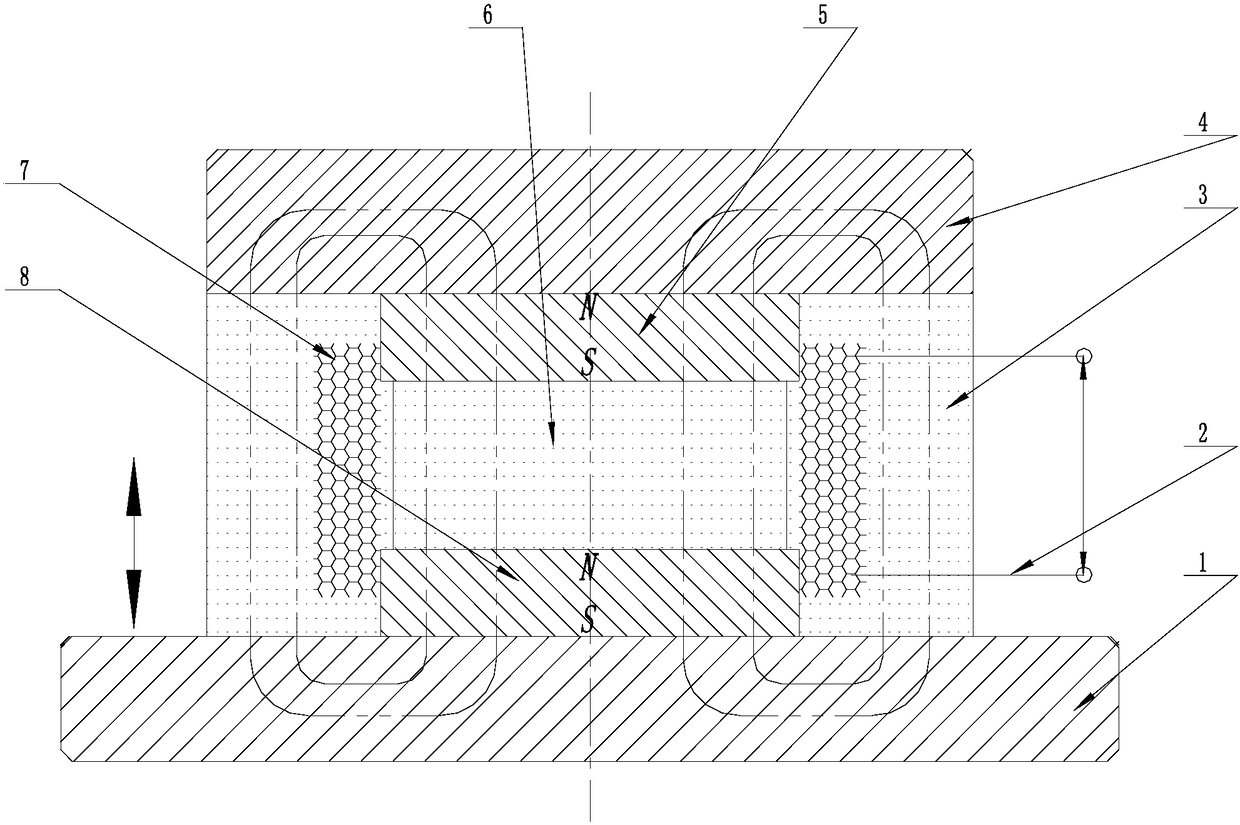

[0021] The present invention will be further described below in conjunction with accompanying drawing and embodiment: figure 1 It is a schematic diagram of the principle of the present invention.

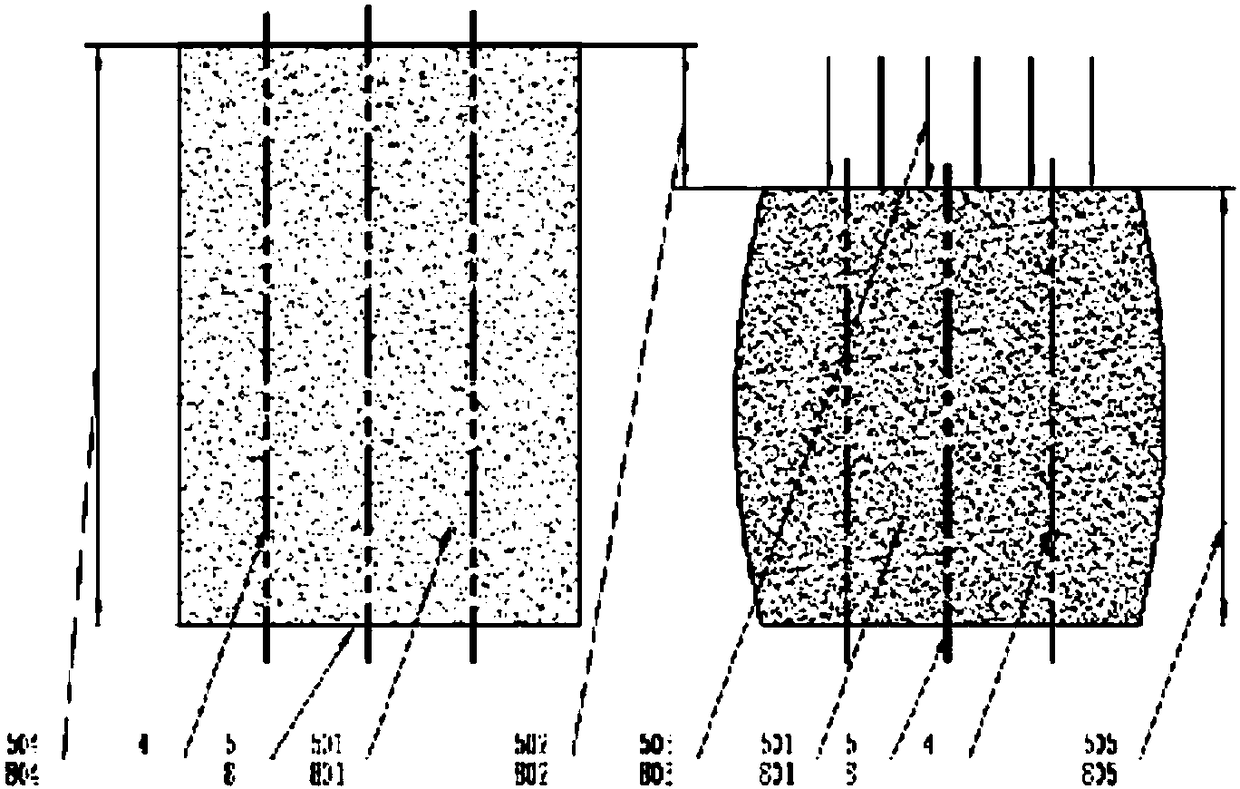

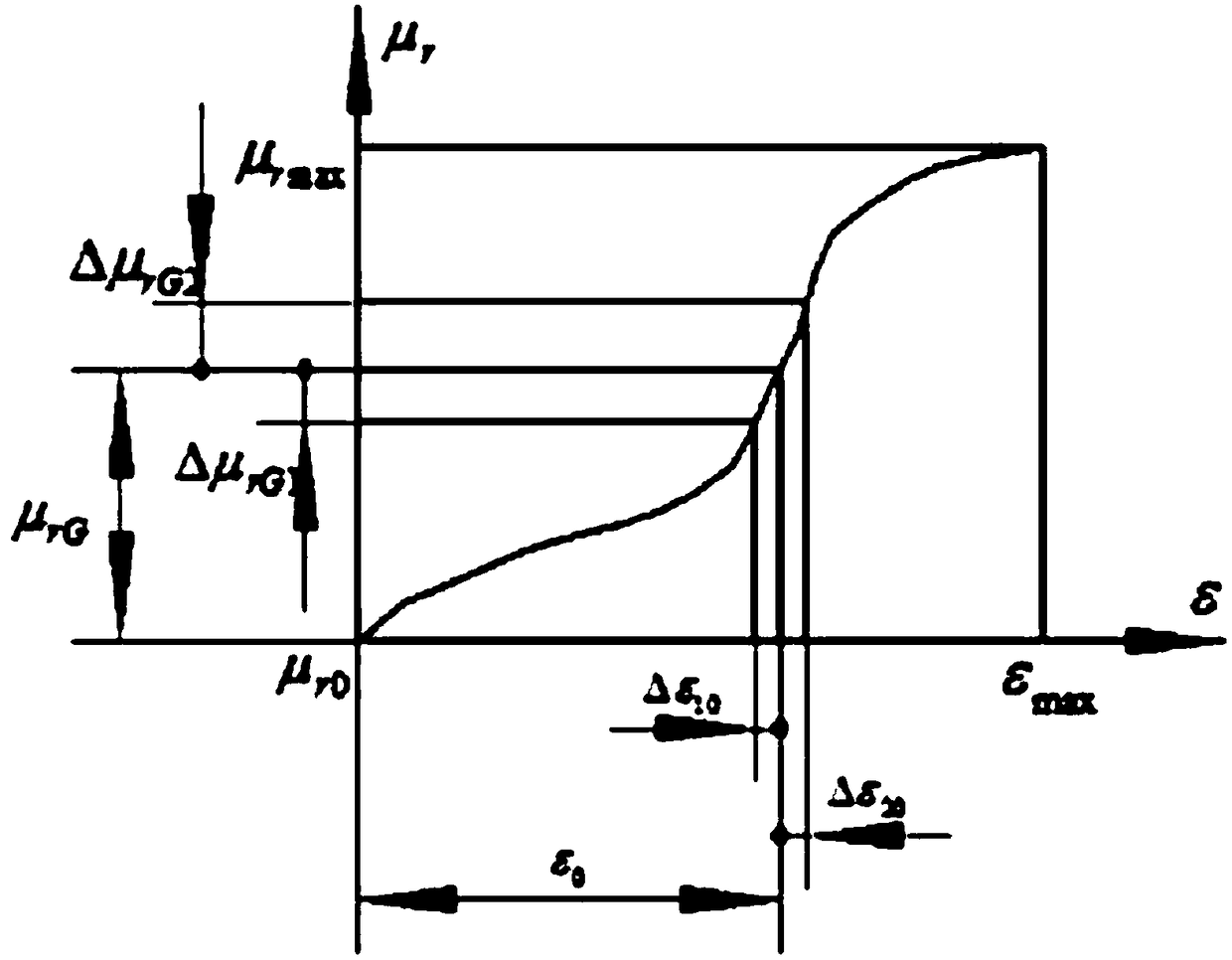

[0022] like figure 1 As shown, the vibration motor based on the force-sensitive elastomer material in this embodiment includes an inductance coil, a magnetic source, a force-sensitive elastomer for generating deformation under the action of an external force and changing the magnetic flux rate in the magnetic circuit, and a force-sensitive elastomer for A vibration conversion unit that converts external vibration into reciprocating motion along the axial direction of the inductance coil; the force-sensitive elastic body is driven by the vibration conversion unit to generate deformation when external vibration occurs, thereby changing the magnetic flux rate, and generating an induced electromotive force through the inductance coil. In this embodiment, the change of magnetic flux in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com