Method for applying a viscous material

A material and coating technology, applied in chemical instruments and methods, devices for coating liquid on the surface, coating, etc., can solve problems such as no further processing, starting point hardening of material strips, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

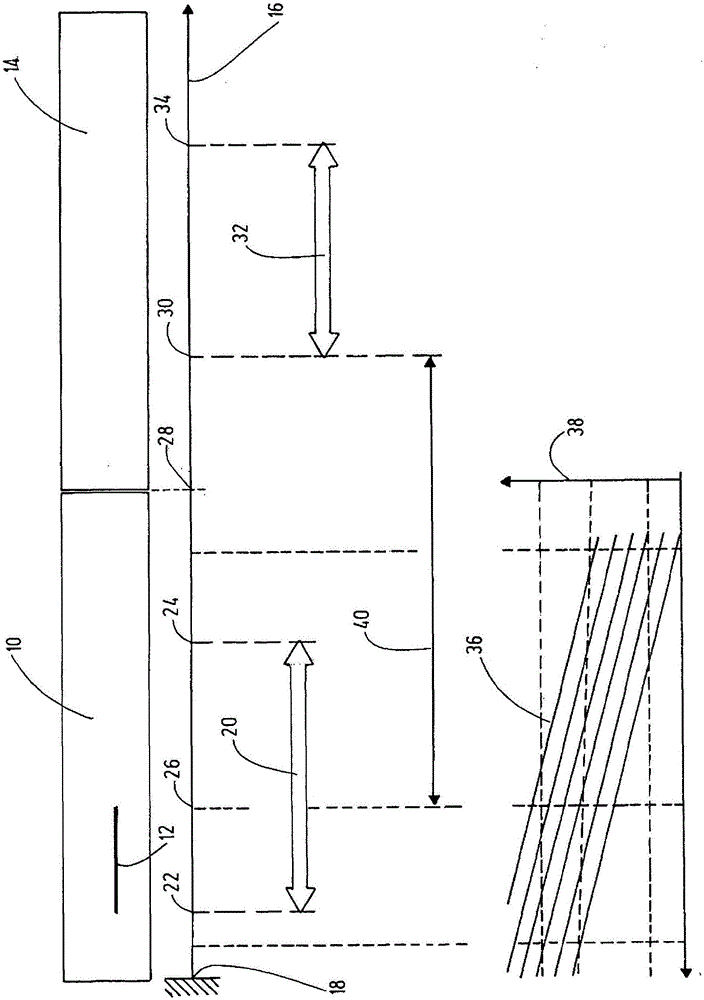

[0012] The figure shows schematically in graph form how a two-component adhesive consisting of a base component and a base hardener is applied in an application station 10 in the form of an adhesive strip 12 to a workpiece, which At a later point in time another workpiece is joined in the joining station 14 . The sequence of working steps is schematically shown by a time axis 16 whose zero point 18 coincides with the point in time at which the workpiece is introduced into the application station 10 . The adhesive application process 20 starts at an application start time 22 and ends at an application end time 24 . In the drawing, the adhesive strip 12 is shown schematically at an application point in time 26 between the application start time point 22 and the application end point in time 24 . At a transfer point in time 28 , the workpiece is transferred from the application station 10 to the joining station 14 . At a further processing start point in time 30 after the trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com