Tire for winter

A technology for tires and treads, which is applied to tire parts, tire treads/tread patterns, transportation and packaging, etc. It can solve the problems of reduced edge effects, reduced handling stability, and reduced friction, and achieves excellent ice performance. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

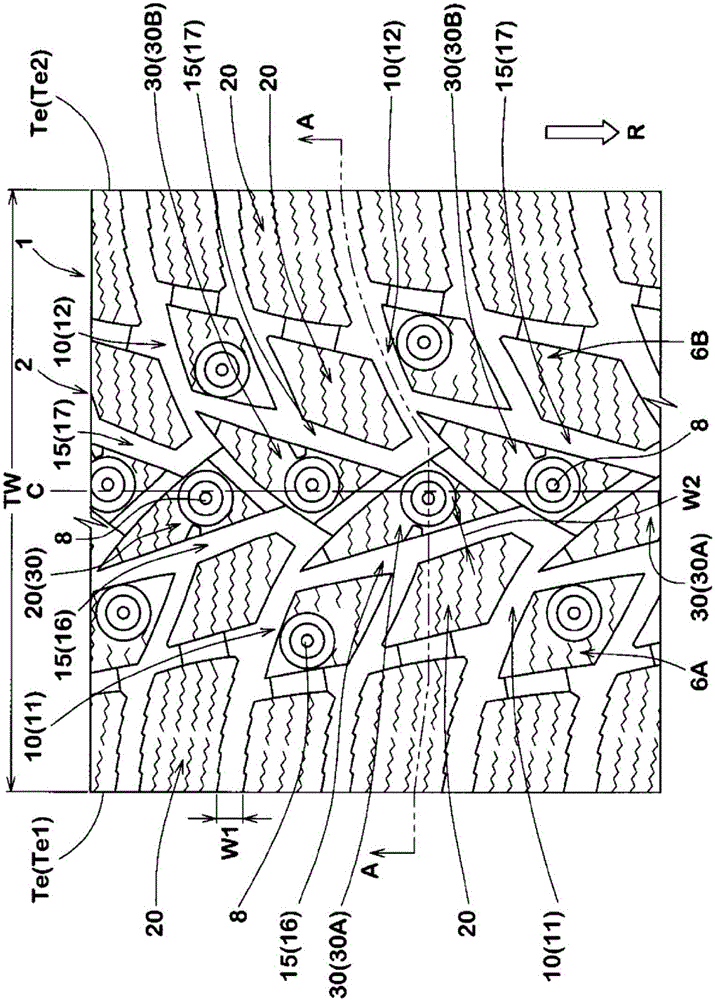

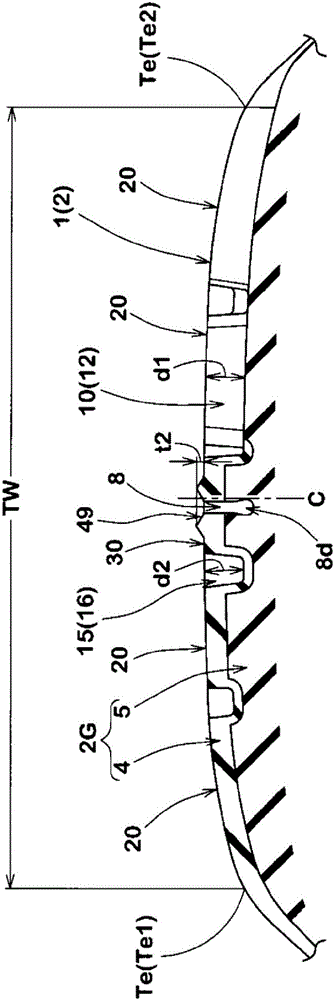

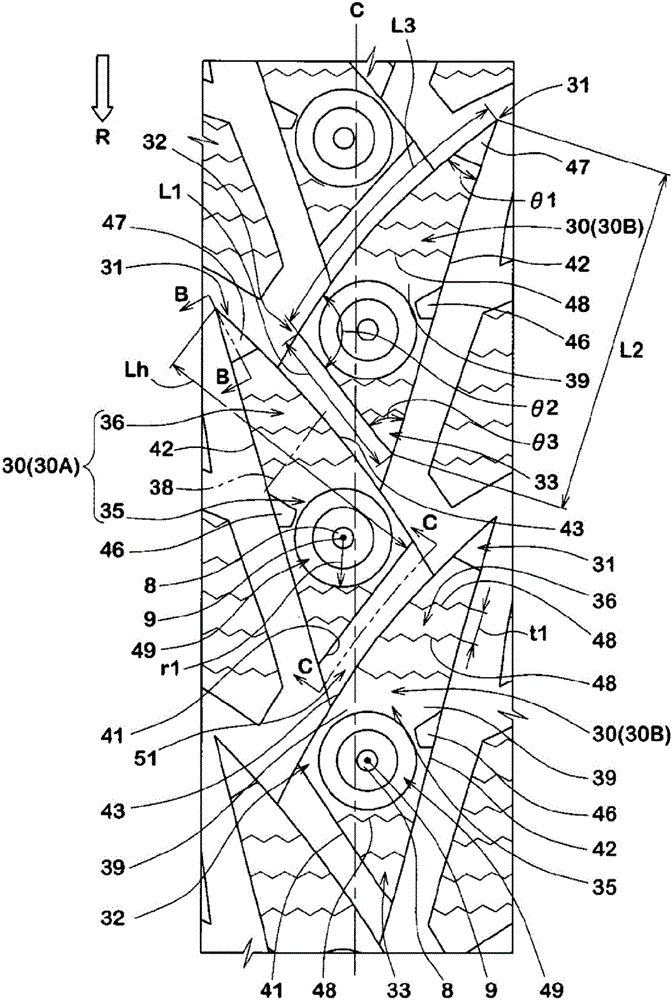

Image

Examples

Embodiment

[0076] Prototypes based on the specifications in Table 1 have figure 1 Winter tires for cars with a basic pattern size of 205 / 60R16. As Comparative Example 1, a winter tire in which pins were provided only on blocks having substantially rectangular treads was trial-manufactured. Grip performance on ice, handling stability on ice, and pin holding performance of each test tire were tested. Common specifications and test methods for each test tire are as follows.

[0077] Mounting rim: 16×6.5

[0078] Tire internal pressure: front wheel 240kPa, rear wheel 220kPa

[0079] Test vehicle: front-wheel drive vehicle (displacement 2000cc)

[0080] Tire installation position: all wheels

[0081]

[0082] The grip performance on ice of the test vehicle mounted with each test tire was evaluated according to the driver's senses. The results are represented by a score of 100 for Comparative Example 1. The larger the score, the better the grip performance on ice.

[0083]

[0084] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com