Anti-blockage hydraulic classifier

A hydraulic classifier and anti-clogging technology, which is applied in the direction of solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of blockage of the discharge port, affecting the classification accuracy, and affecting the progress of the classification, so as to prevent material blockage and improve Stable output and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

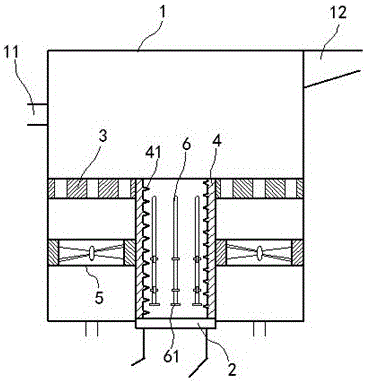

[0015] exist Figure 1 to Figure 3 In the shown embodiment, the anti-clogging hydraulic classifier includes a classification chamber 1, a feed pipe 11 and an overflow pipe 12 are respectively installed on the upper part of the classification chamber 1, and a water inlet and a discharge pipe are provided at the bottom of the classification chamber 1. feed port 2;

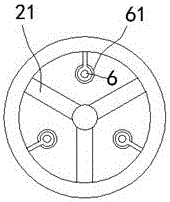

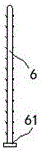

[0016] A sieve plate 3 is fixed in the classification chamber 1, and a discharge cylinder 4 is installed between the sieve plate 3 and the discharge port 2. The upper end of the discharge cylinder 4 runs through the sieve plate 3, and the discharge cylinder 4 can The axis rotates freely; the inner wall of the discharge cylinder 4 is engraved with spiral diversion lines 41, and the outer wall of the discharge cylinder 4 is engraved with transmission stripes; in the classification chamber 1, below the sieve plate 3, a hydrodynamic turbine 5 is also installed. , the rotating shaft of the hydrodynamic turbine 5 is coinc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com