Weld seam glue sealing device

A technology of sealing device and glue supplying device, which is applied in the direction of surface coating liquid device, coating, etc., can solve the problems of unstable extrusion of weld sealant and the inability of the glue strip to be continuously formed at one time, so as to achieve easy control. Glue supply, opening and resetting are convenient, and the effect of improving sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

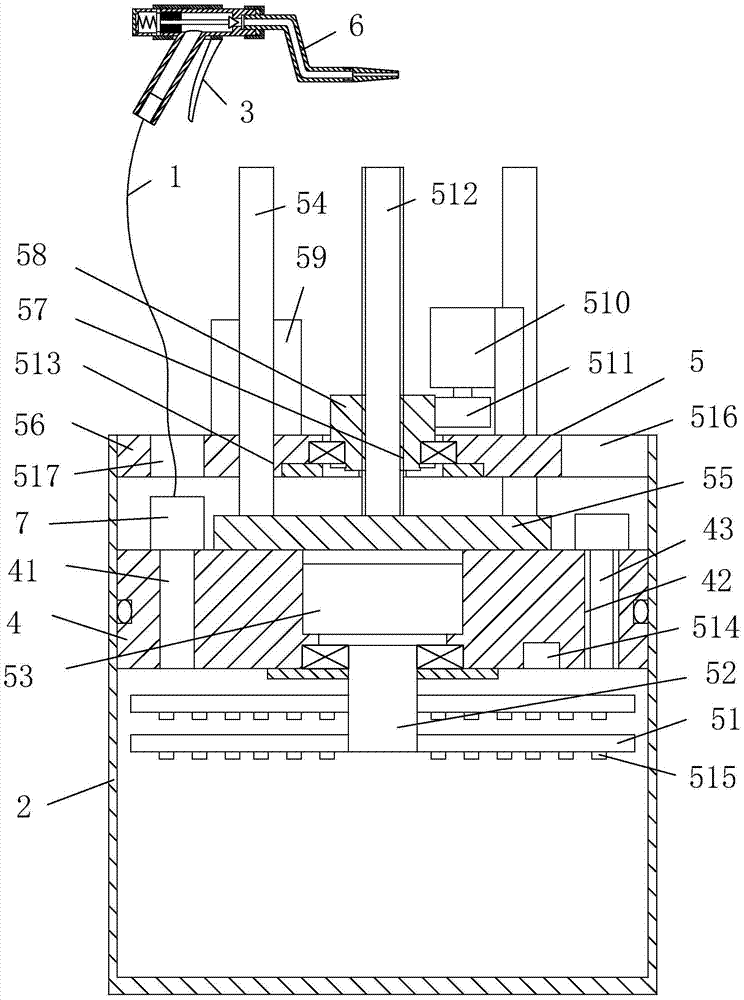

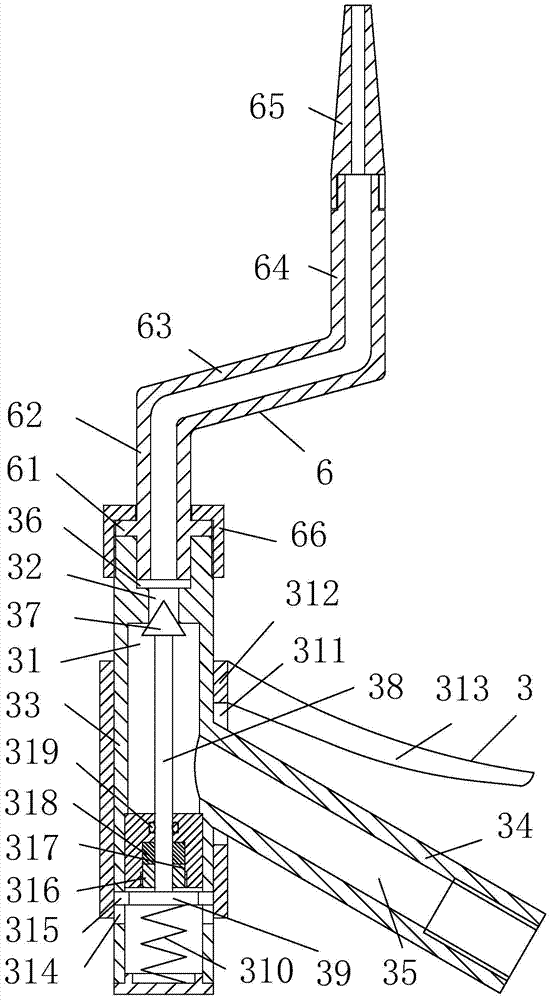

[0018] as attached figure 1 , attached figure 2 Shown: a welding seam glue sealing device, including: a glue gun 3 with a rubber inlet pipe 1, and a glue supply device; The lift-type pressure-stabilizing glue-pressing device 5 of the slide plate 4 surrounding the inner gap; the slide plate 4 is provided with glue supply holes 41 having the same number as the glue guns 3; one end of each glue inlet pipe 1 is connected with a glue supply hole 41 The glue gun 3 is provided with a curved gun head 6; in this embodiment, the outlet of the glue supply hole 41 is provided with a cut-off valve 7 connected to one end of the rubber inlet pipe 1; the cut-off valve 7 is an electromagnetic cut-off valve.

[0019] Described gluing gun 3 comprises: the frame 33 that is provided with middle hole 31 and the glue hole 32 that the rear end communicates with the front end of middle hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com