Feeding mechanism and feeding method thereof

A technology of feeding mechanism and feeding trough, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of increasing the structure of automatic production equipment, reducing the production efficiency of enterprises, and taking a long time for feeding materials, so as to achieve simplification structure, improve production efficiency, and high feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

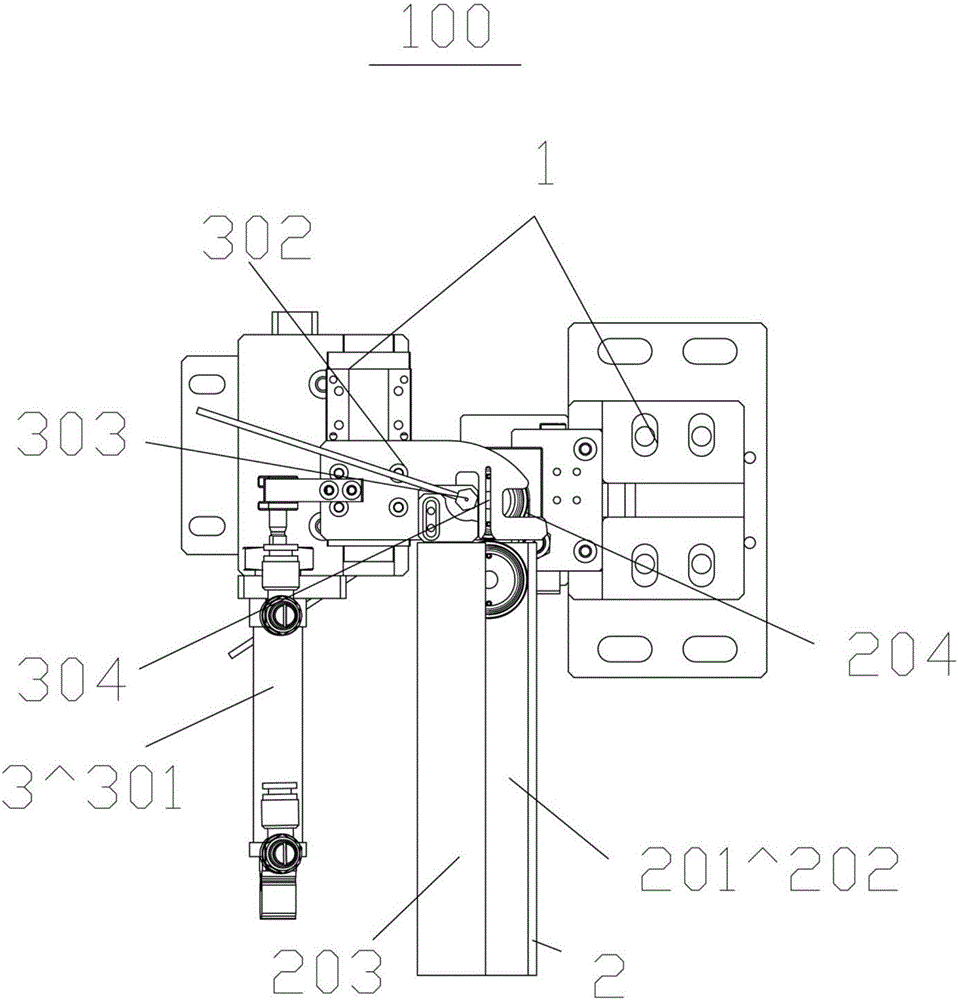

[0038] refer to figure 1 , the present embodiment provides a feeding method, which uses a feeding mechanism that includes a correspondingly arranged and used feeding device 100 and a rotatable feeding jaw device (not shown in the figure) to control the water control membrane. carry out feeding;

[0039] The feeding device 100 includes a base plate 1, a feed trough plate 2 arranged on the base plate 1, a detection device 3 arranged on the base plate 1 and used in conjunction with the feed trough plate 2;

[0040] The feeding trough plate 2 includes a feeding plate 202 on which the feeding trough 201 is arranged on the base plate 1, and a height limit that is fixedly arranged on one side of the feeding plate 202 and covers 50% of the feeding trough 201 Positioning plate 203;

[0041] Loading includes the following steps:

[0042] 1) The water control diaphragm is fed through the feeding trough plate 2, and the water control diaphragm with the opposite vertical direction is di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com