Turnover equipment and turnover method suitable for plate processing

A plate processing and plate technology, which is applied to the turnover equipment and turnover field for plate processing, can solve the problems that affect the quality of plate processing, wear of plate surface, mutual collision friction, etc., and achieve improved protection effect, reduced working intensity, and uniform force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

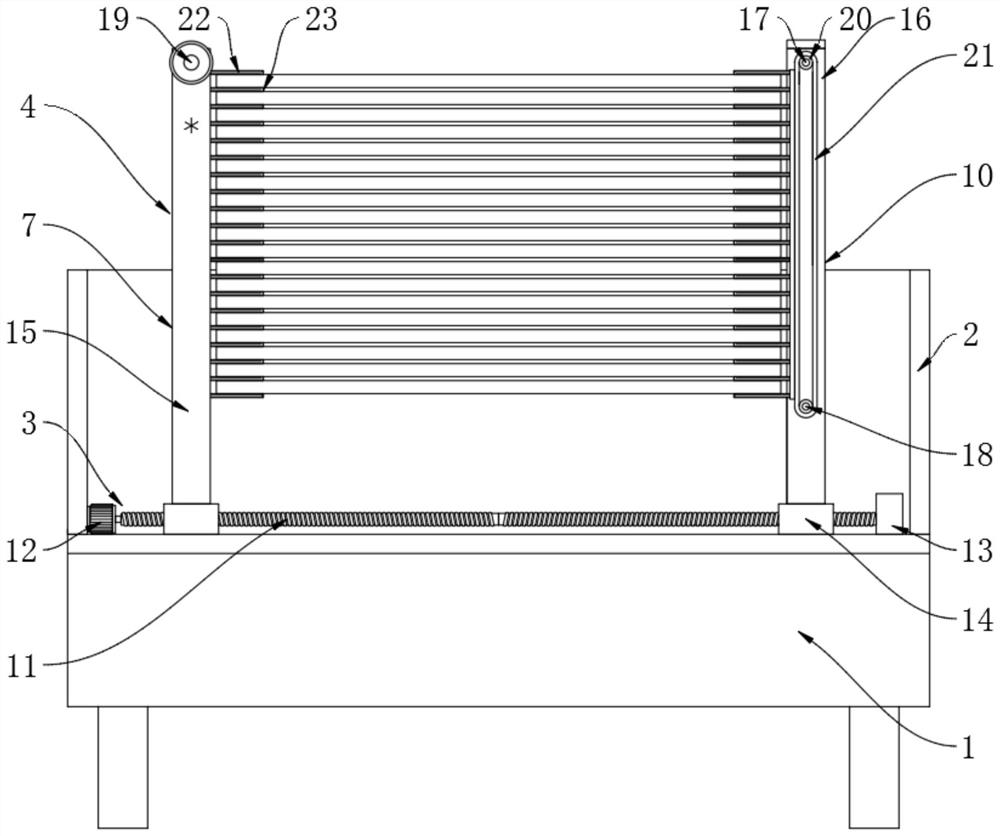

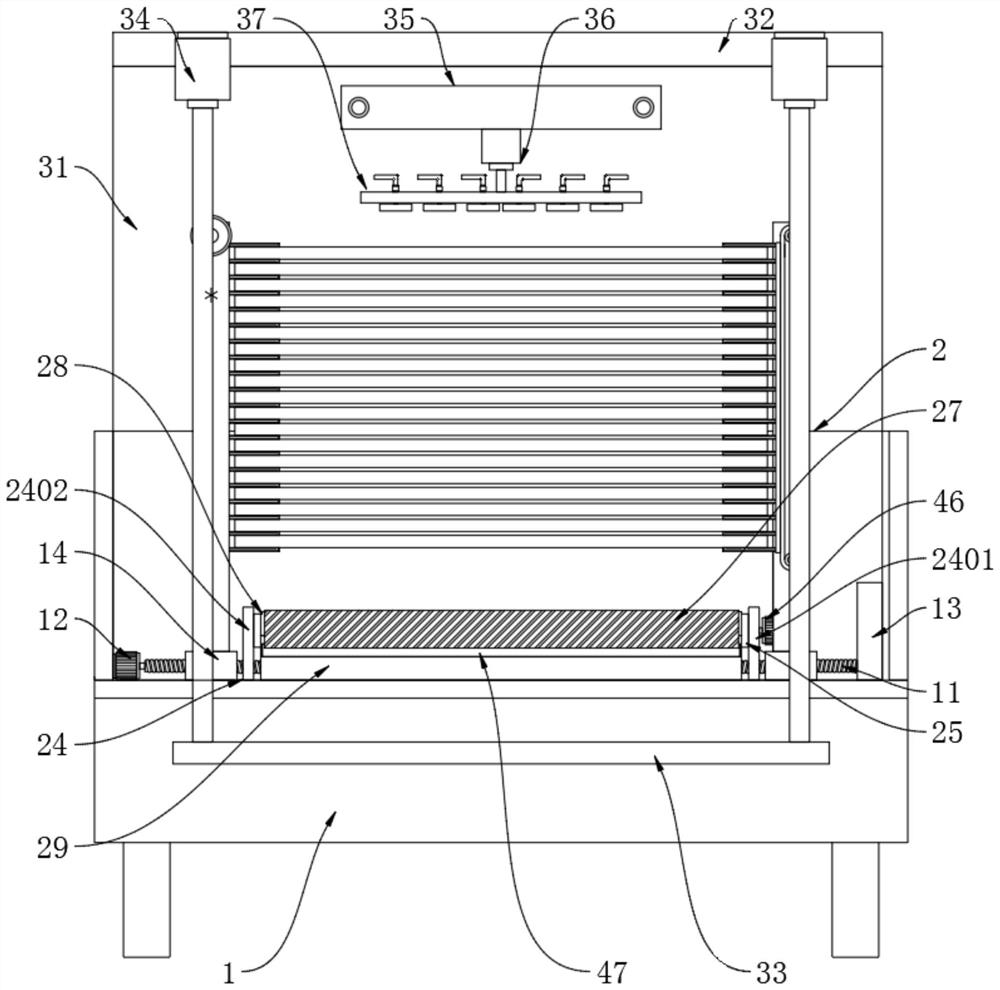

[0062] refer to image 3 and Figure 4 , the interior of the compartment 2 also includes a discharge mechanism, which is located between the two translation structures 4;

[0063] The unloading mechanism includes two mounting plates 24, the mounting plate 24 is connected with the bottom of the compartment 2 as a whole, a power shaft 25, a power transmission shaft 26 and a transmission belt 27 are arranged between the two mounting plates 24, and the power shaft 25 and the power transmission shaft 26 are connected together. Transmission belt 27 is installed between transmissions;

[0064] The two mounting plates 24 include a first plate body 2401 and a second plate body 2402, the outside of the first plate body 2401 is fixedly installed with a power motor 46, and one end of the power shaft 25 passes through the first plate body 2401 and is connected to the output of the power motor 46 Shaft fixed connection;

[0065] Also fixedly install shock absorbing block 28 and base bloc...

Embodiment 3

[0077] refer to image 3 and Figure 4 , the interior of the compartment 2 also includes a feeding mechanism;

[0078] The feeding mechanism is installed on the connecting frame 31, and the feeding mechanism includes a horizontal transmission part 35, a lifting part 36 and a plate extraction part 37;

[0079] The horizontal transmission part 35 drives the lifting part 36 to move between the exterior of the compartment 2 and the inner cavity.

[0080] The use of the feeding mechanism can realize the automatic feeding of the plates and further enhance the automation of equipment use. When in use, the horizontal transmission part 35 first drives the lifting part 36 to move until it moves from the top of the compartment 2 to the outside of the compartment 2, and the compartment 2 Plates are stacked on the outer bottom surface, and the lifting part 36 runs, driving the plate extracting part 37 to move down until the plate extracting part 37 picks up the plate, the lifting part 36...

Embodiment 4

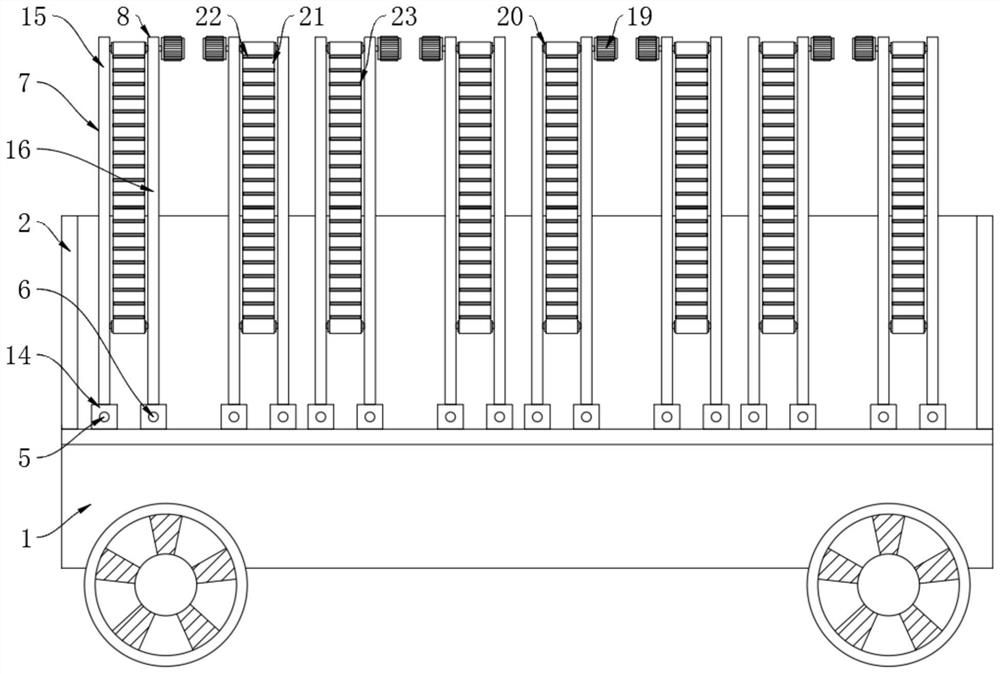

[0088] refer to figure 2 or Figure 4 , according to the size of the compartment 2, there are multiple plate retaining mechanisms, and the multiple plate retaining mechanisms are arranged along the transmission direction of the transmission belt 27.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com