Production system applied to wooden photo frames

A production system and technology of photo frames, applied to wood processing equipment, manufacturing tools, conveyor objects, etc., can solve problems such as time-consuming and labor-intensive, difficult to control the production quality of photo frames, and no mutual correlation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

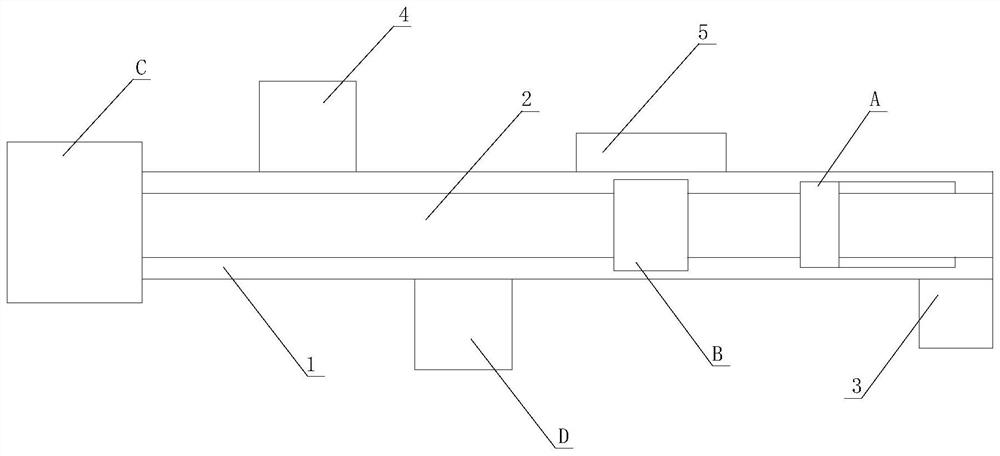

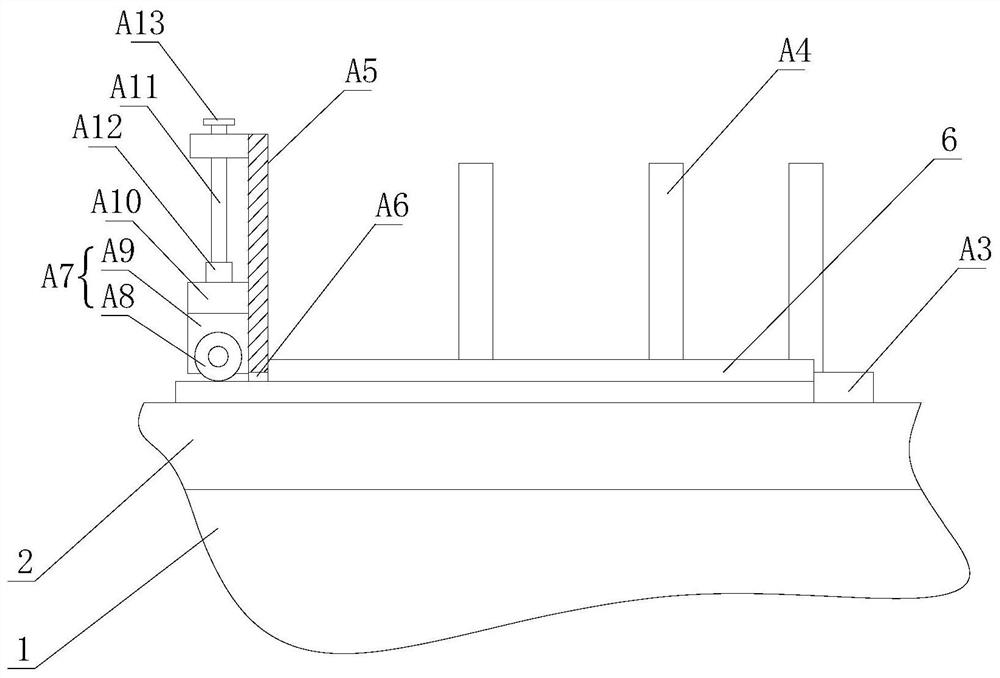

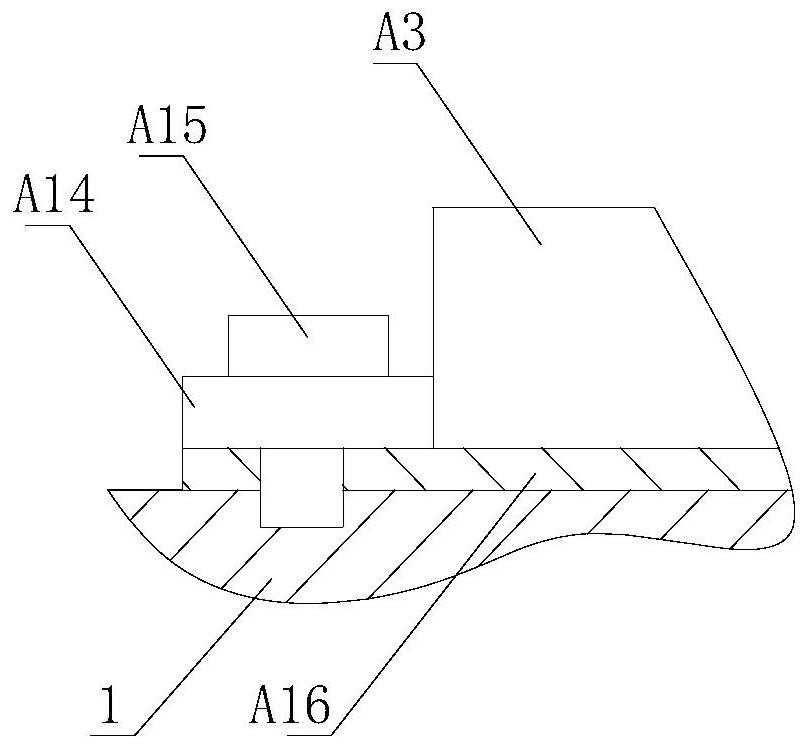

[0043] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 Shown, a kind of production system for wooden picture frame comprises frame 1, and described frame 1 is provided with conveyer belt 2, and described frame 1 is provided with cutting device 3, and described cutting device 3 is used for cutting raw material into Make the picture frame bar 6 of picture frame, the cutting device in the present embodiment is prior art, present embodiment does not describe in detail, is also provided with feeding device A, detection device B, puller along the frame described in conveyer belt 2 conveying modes. Groove device D, assembly platform 4 and pulling hole device C, described cutting device 3 is arranged on the frame 1 side of conveyor belt feeding end, and described feeding device A is arranged on the frame 1 of conveyor belt feeding end, and described detection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com