A kind of automatic winder intubation device and intubation method

An automatic winding machine and intubation technology, which is applied in the direction of conveyor objects, transportation and packaging, and delivery of filamentous materials, etc. It can solve the problems of difficulty in increasing the intubation speed, large bobbin motion inertia, and reduced intubation efficiency. , to achieve the effects of reduced failure rate, small motion inertia and high intubation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in further detail below in conjunction with accompanying drawing:

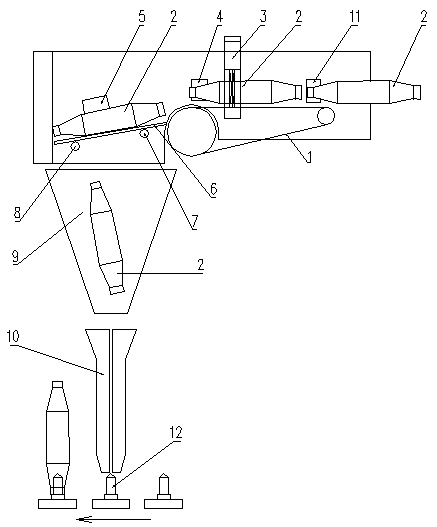

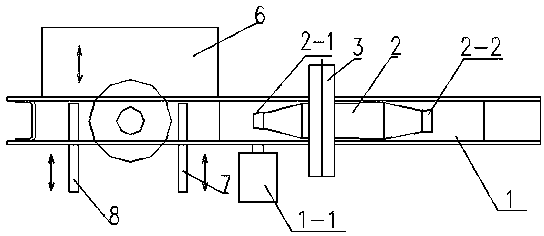

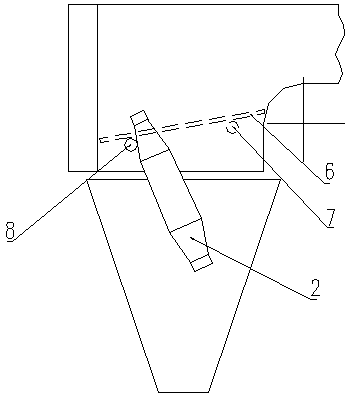

[0025] see Figure 1-Figure 4 , an embodiment of an automatic winding machine intubation device of the present invention, comprising a bobbin conveying device, a bobbin judging device, a bobbin releasing device arranged near the output end of the bobbin conveying device, a tray 12, and a The guiding positioning device and the control system above the tray 12. The bobbin release device includes a first support body 6, a second support body 7, a third support body 8 and a telescoping drive mechanism arranged above the guide positioning device, and the control system is based on the bobbin size end judging device Judgment results control the telescopic drive mechanism to drive the telescopic actions of the first support body 6, the second support body 7, and the third support body 8, and transport the bobbin delivery device to the first support body 6 in the bobbin relea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com