Self-adaption damping elevator well damping assembly

An elevator shaft and self-adaptive technology, applied in elevators, transportation and packaging, etc., can solve problems such as complex driving structure, unfavorable follow-up intervention of springs and damping parts, and low accuracy of damping force control, so as to improve safety performance and achieve smooth operation sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

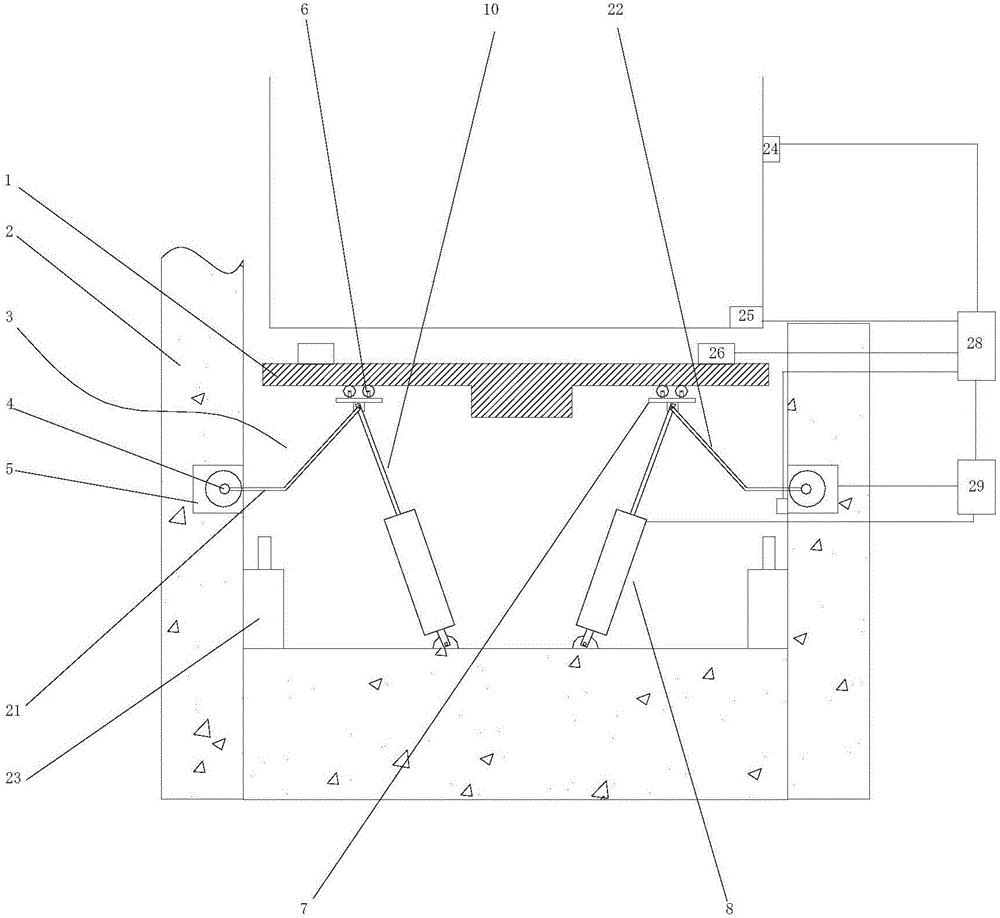

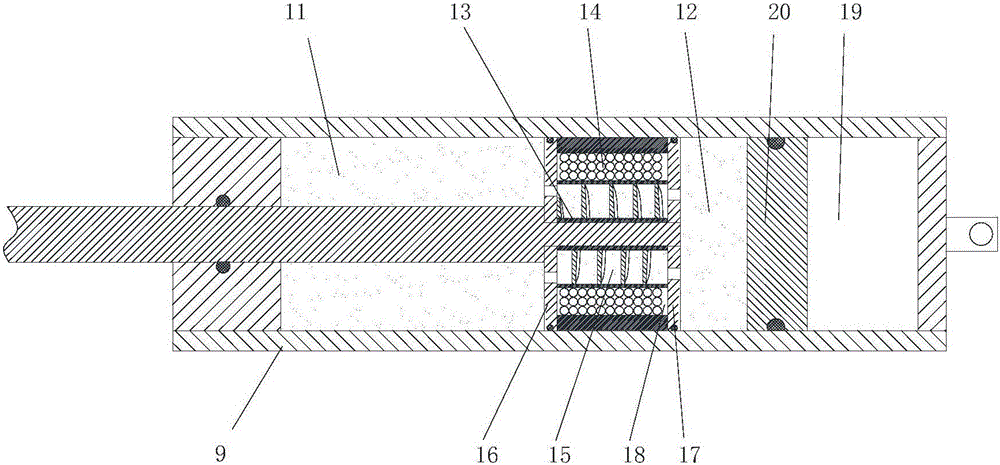

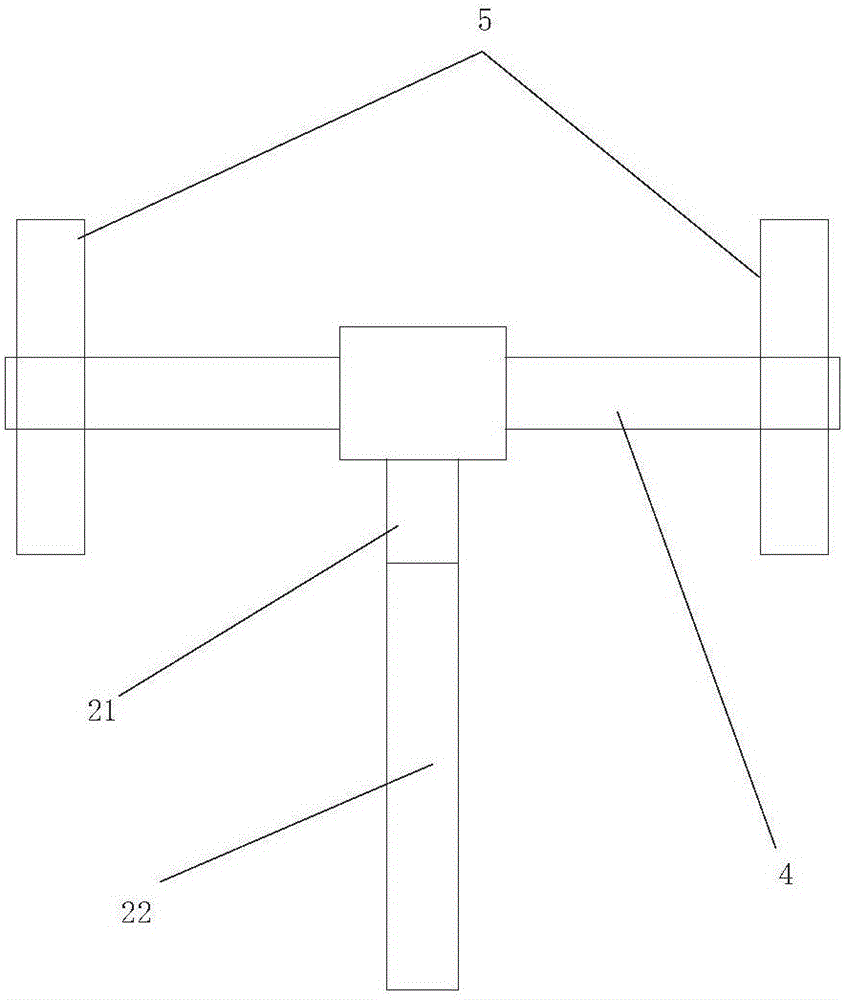

[0024] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is a structural schematic diagram of a cylindrical magneto-rheological damper in the present invention, image 3 It is a structural schematic diagram of the lifting arm and the rotating magneto-rheological damper in the present invention. As shown in the figure, the adaptive damping elevator shaft damping assembly in this embodiment includes And provide the buffer plate 1 of the buffer force, the magnetorheological damping device for providing the upward damping force for the buffer plate 1 and the control system for controlling the output of the damping force of the magnetorheological damping device; the magnetorheological damping device is fixed on On the bottom foundation 2 of the elevator shaft, the magnetorheological damping device includes at least four sets of rotating magnetorheological damper assemblies arranged along the circumference of the elevator shaft, distributed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com