Combined type demisting device

A demisting device and a combined technology, applied in the field of desulfurization towers, can solve the problems of demisting efficiency, desulfurization efficiency decline, affecting the normal operation of desulfurization process, waste of manpower and material resources, etc., to save labor costs, reduce input costs, increase The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

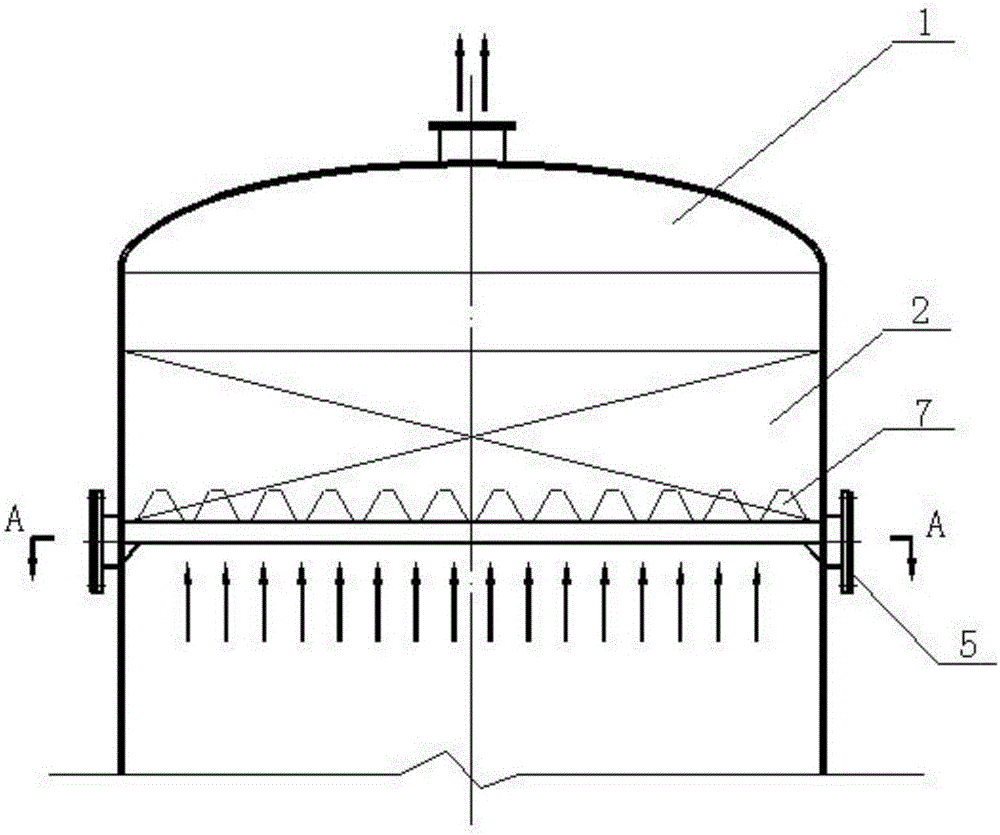

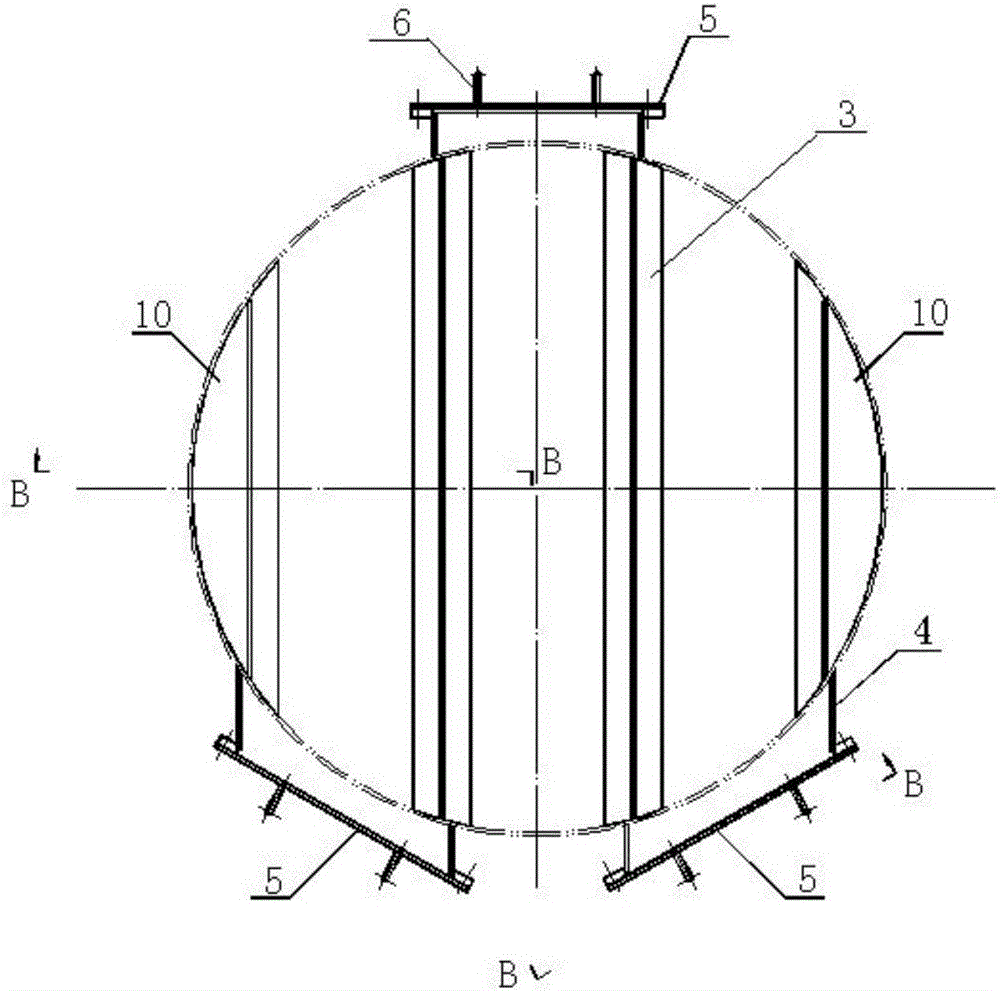

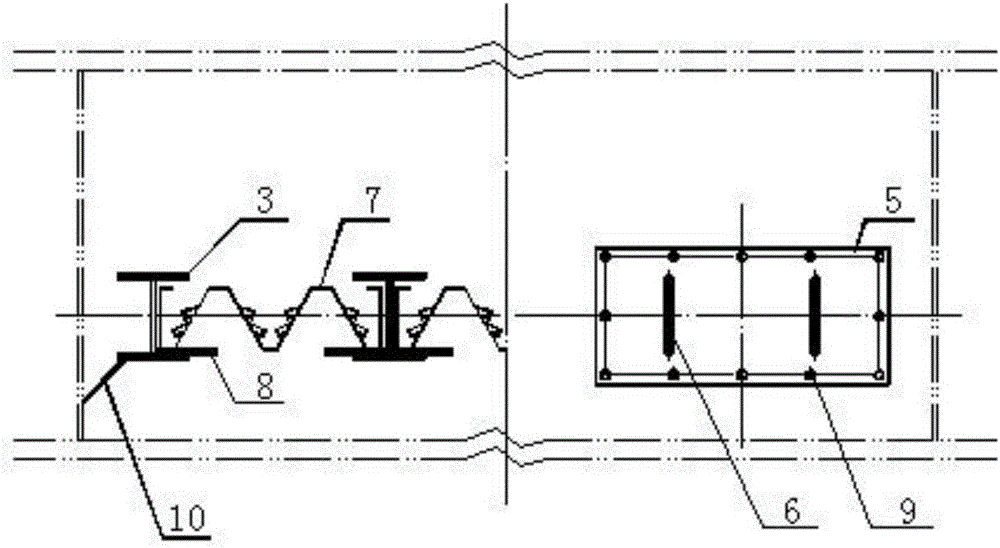

[0023] Such as figure 1 As shown, a combined demister device according to the present invention includes a mist trapping packing 2 and a packing support beam 3 arranged in the desulfurization tower 1 and at the top of the desulfurization tower, and a plurality of packing support beams 3 arranged in parallel are located at the top of the desulfurization tower. The bottom of the filler 2 supports the mist trap filler 2; it also includes a plurality of drawer structures 7 arranged between the filler support beams 3, the main body of the drawer structure 7 is a thin-walled plate with trapezoidal waves, and the hypotenuse of the trapezoidal waves A plurality of through holes are evenly distributed from the inside to the outside and obliquely downward; the drawer structure 7 can slide along the track structure on the packing support beam 3 and be drawn ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com