A multifunctional gas-liquid comprehensive heat exchange device

A heat exchange device and multi-functional technology, applied in refrigeration and liquefaction, lighting and heating equipment, evaporator/condenser, etc., can solve the problem of increasing thermal resistance between heat exchange tubes and water, low heat exchange efficiency, and refrigeration Insufficient heat exchange between solvents, water, and air, etc., to achieve the effects of improving heat exchange efficiency, realizing multi-functionality, achieving functional diversity and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

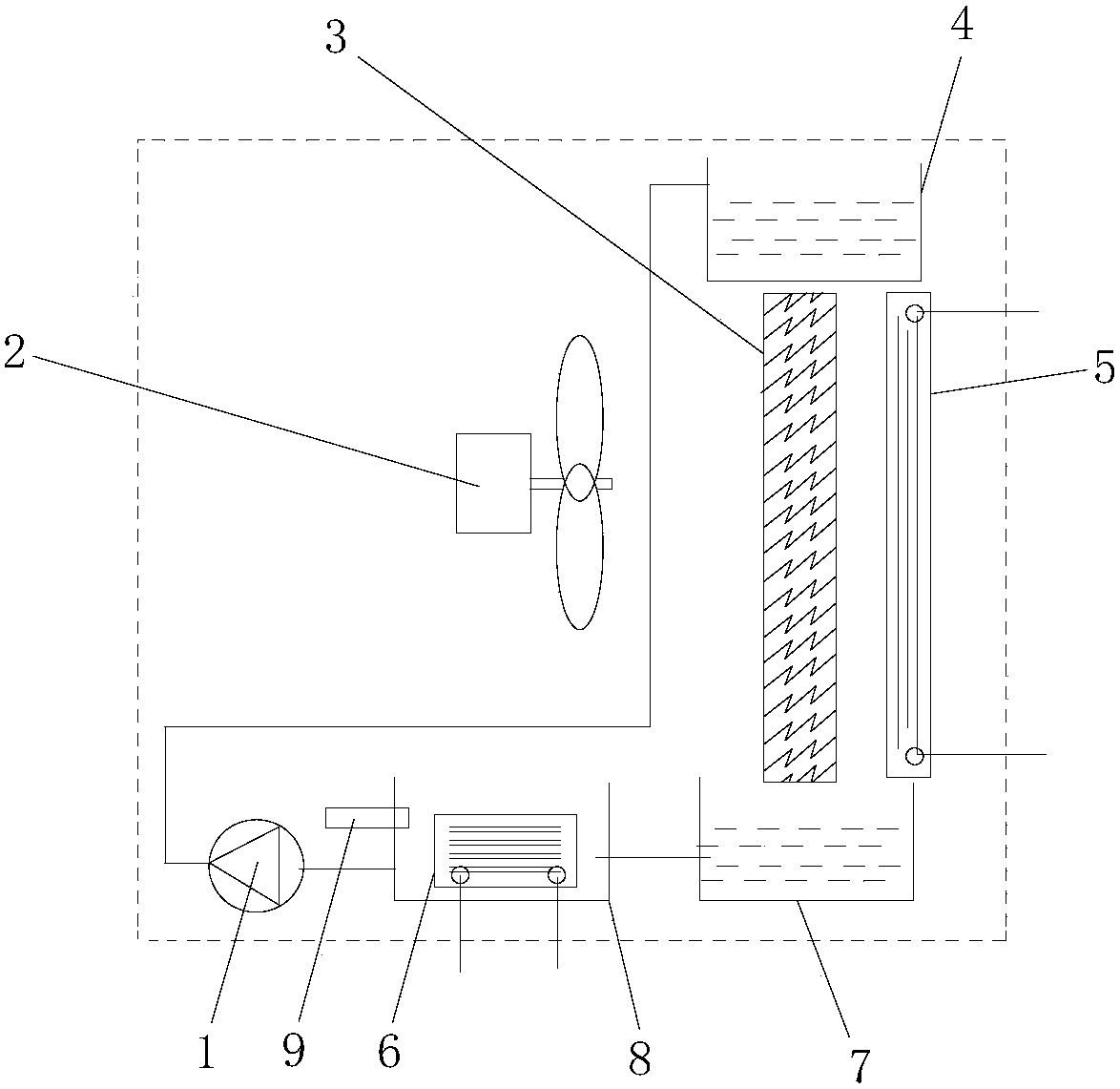

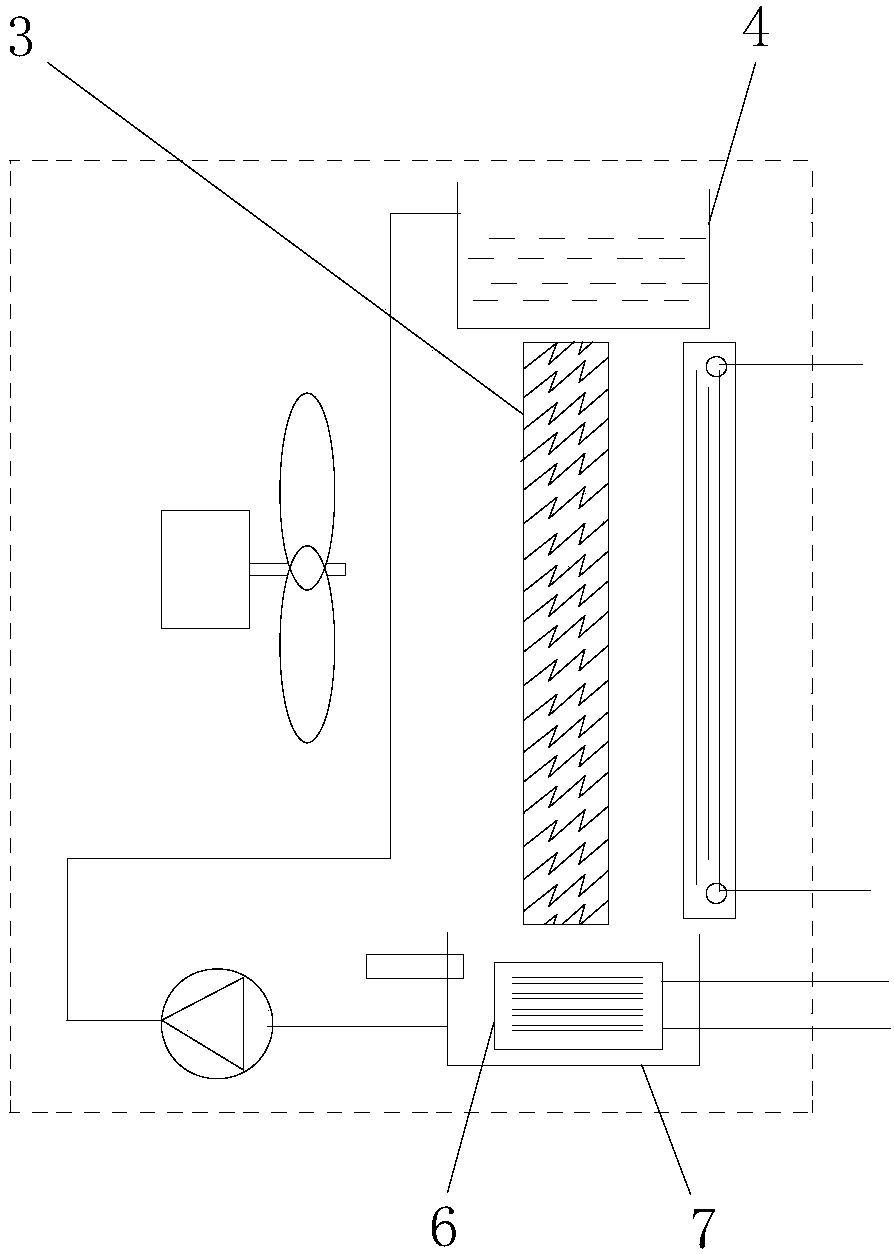

[0050] A multifunctional gas-liquid comprehensive heat exchange device, comprising a liquid pan, a liquid pump 1, a fan 2, a filler 3, a liquid shower device and a heat exchanger, the inlet and outlet of the heat exchanger are respectively connected to the heat exchange circuit, and the The heat exchanger includes heat exchanger Ⅰ5 and heat exchanger Ⅱ6 connected in series with heat exchanger Ⅰ. Heat exchanger Ⅰ is placed on the filler side, and heat exchanger Ⅱ is placed in the liquid pan or shower device; the air blown from the fan After the filling is blown to the heat exchanger Ⅰ, the liquid pump is connected to the liquid pan. When cooling, the cooling liquid is drawn out from the liquid pan and poured onto the packing through the liquid shower device and then flows back to the liquid pan.

[0051] Preferably, the liquid tray includes a liquid receiving tray 7, the liquid shower device is placed above the packing, the liquid shower device is connected to the liquid receivi...

Embodiment 2

[0067] When the present invention is applied to a heat pump air conditioner unit, the connection mode of the heat pump cycle system connected to the outside can be referred to as follows: the exhaust port of the compressor is connected to the air inlet of the four-way reversing valve, and the condensation in the four-way reversing valve The side outlet is connected to the inlet of heat exchanger Ⅰ in the multifunctional gas-liquid comprehensive heat exchange device, the outlet of heat exchanger Ⅰ is connected to the inlet of heat exchanger Ⅱ after passing through the heating throttling component, and the outlet of heat exchanger Ⅱ After passing through the refrigeration throttling component, it is connected to the inlet of the evaporator, the outlet of the evaporator is connected to the air return port of the four-way reversing valve, and the air outlet of the four-way reversing valve is connected to the compressor, thus forming a heat pump type Air conditioning circulation sys...

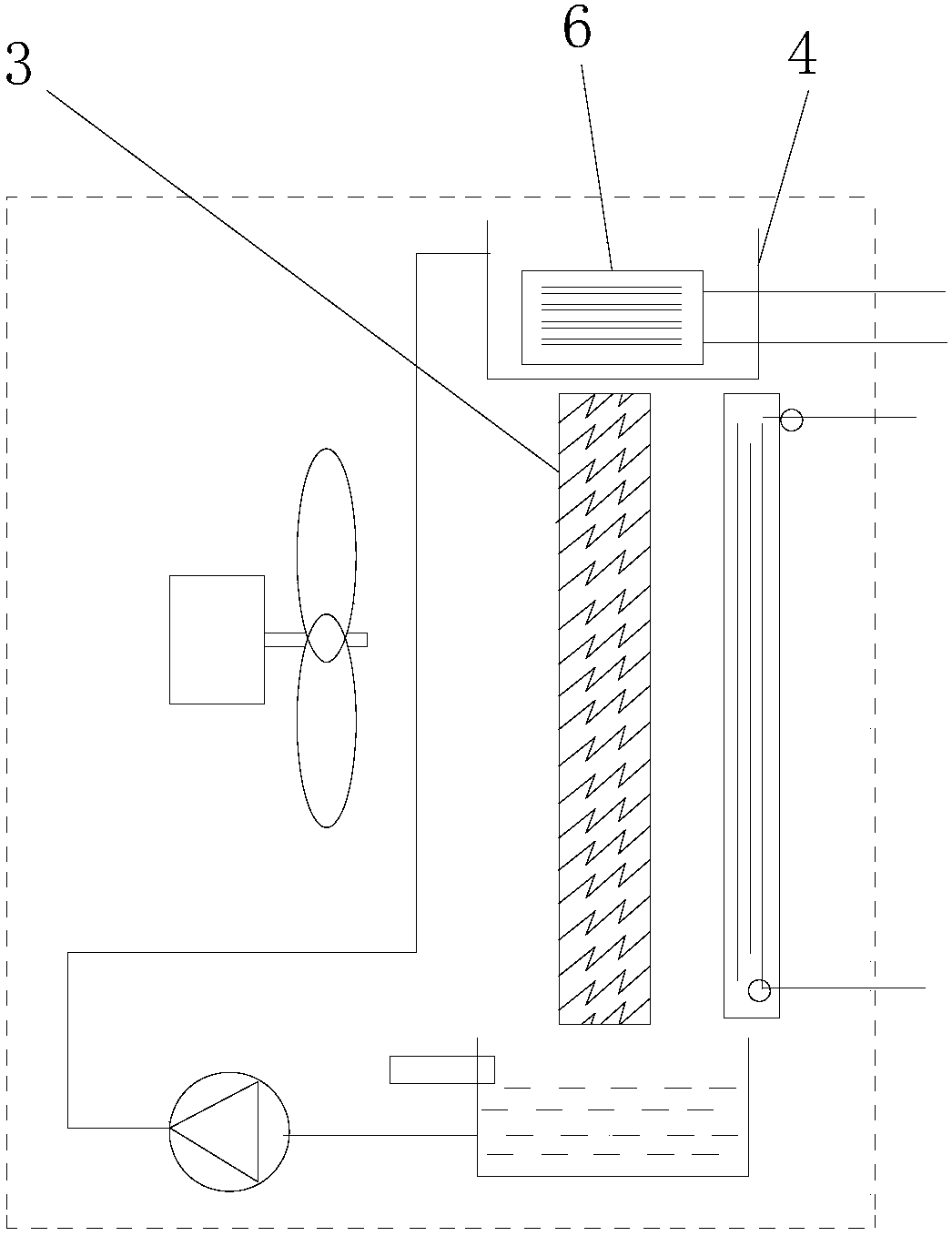

Embodiment 3

[0076] When the present invention operates in a heat pump air conditioner unit and operates the heating function, the liquid pump stops working, the water in the liquid receiving tray is drained, and the evaporator is converted into a heating function. The water in the liquid pan is drained, and the heat exchanger II will no longer be soaked by water. The compressor discharges high-temperature and high-pressure gaseous refrigerant. The gaseous refrigerant first passes through the four-way reversing valve and then enters the evaporator (the evaporator acts as a condenser at this time), and then enters the heat exchange through the bypass channel of the refrigeration throttling component. (When heating, the heat exchanger II is used as a part of the liquid receiver or the pipeline). The medium-temperature and high-pressure liquid refrigerant coming out of the heat exchanger II becomes a low-temperature, The low-pressure liquid refrigerant enters the heat exchanger Ⅰ (when heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com