Level detection method and system for ocean module building

A level detection and marine technology, applied in hydrostatic leveling, measuring devices, surveying and navigation, etc., can solve problems affecting construction accuracy, uneven settlement of support points, stratum damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

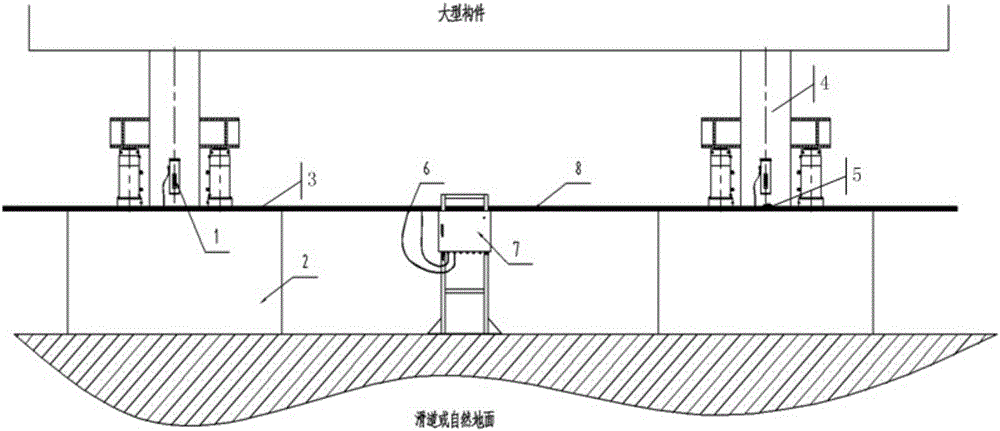

[0014] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

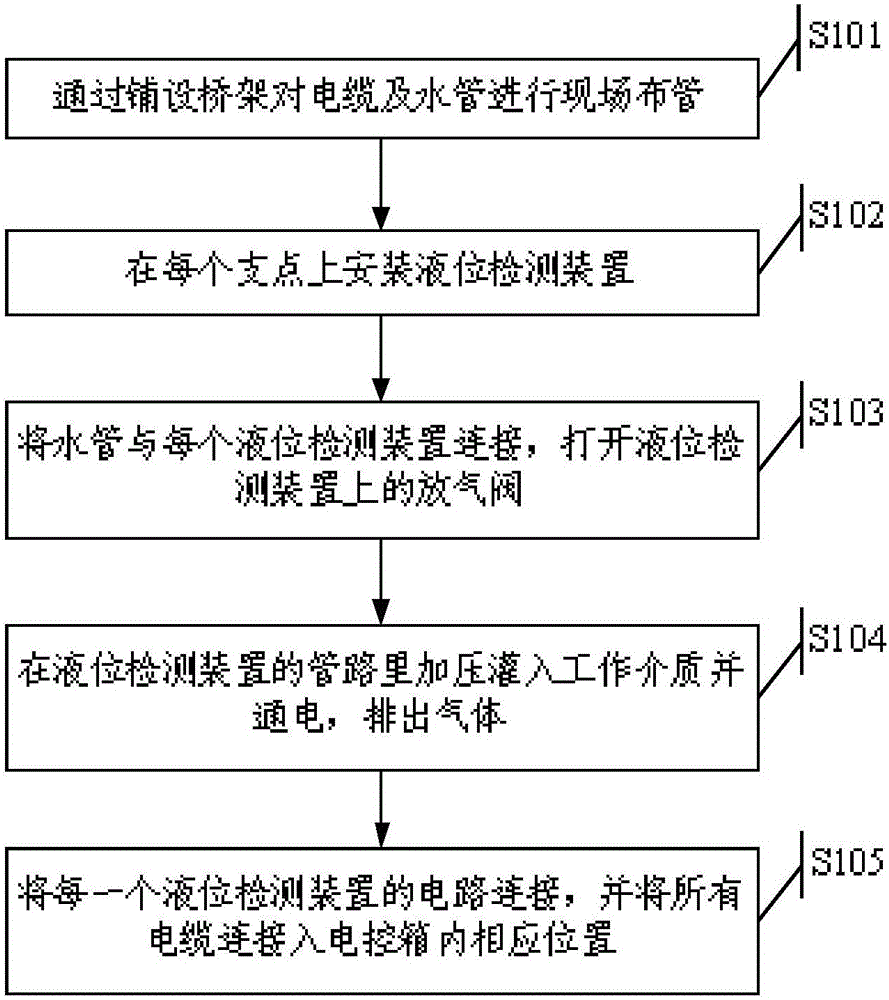

[0015] figure 1 A schematic flow chart of a level detection method for marine module construction provided by an embodiment of the present invention, the method includes:

[0016] S101: Conduct on-site piping for cables and water pipes by laying bridges;

[0017] What needs to be added is that the on-site piping of cables and water pipes is carried out by laying bridges, that is, the pre-piping process, which is the preparation work before the module is built. It has a protective effect and prevents debris such as welding slag from falling during the construction process from damaging the equipment.

[0018] In practical application, the way of laying cables and water pipes on site can be selected according to the actual geology of the site. If the construction foundation is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com