Hydraulic motor inertia loading test device

A technology of loading test device and hydraulic motor, which is applied in the direction of measuring device, using repeated force/pulsation force to test material strength and strength characteristics, etc., to achieve the effect of light weight in quality and size, convenient layout and processing, convenient design and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

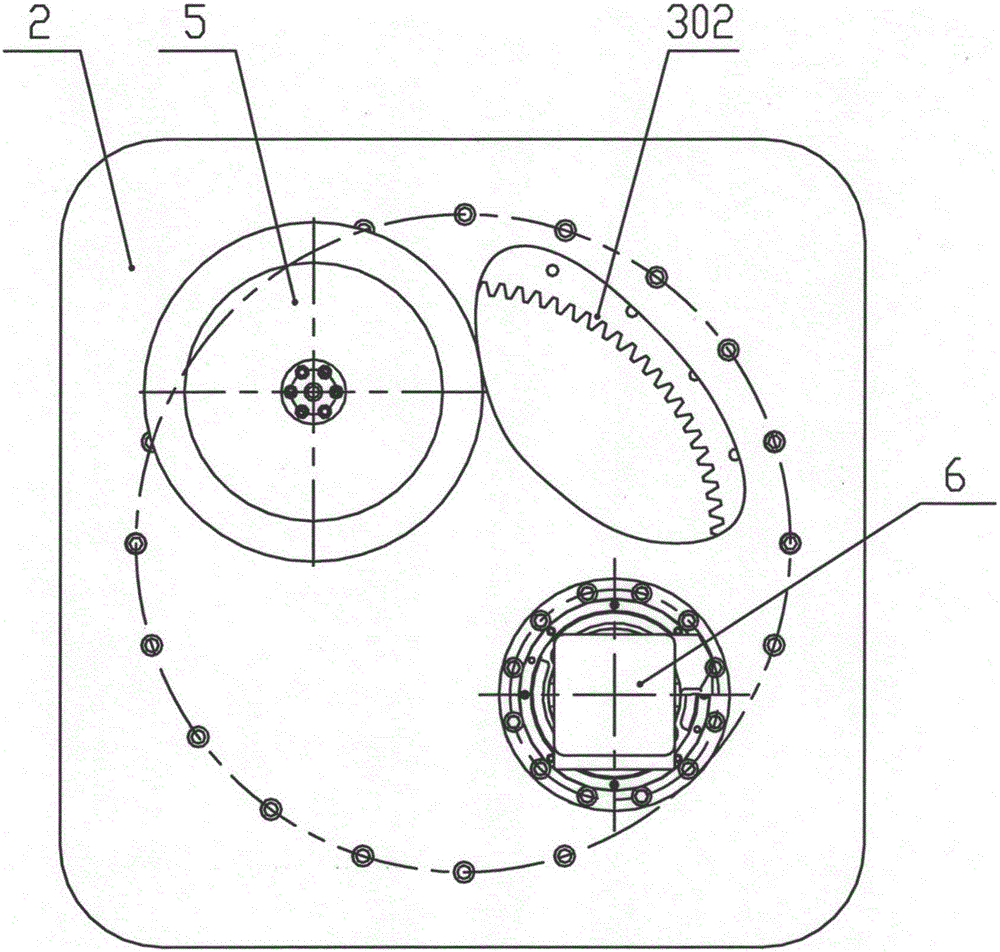

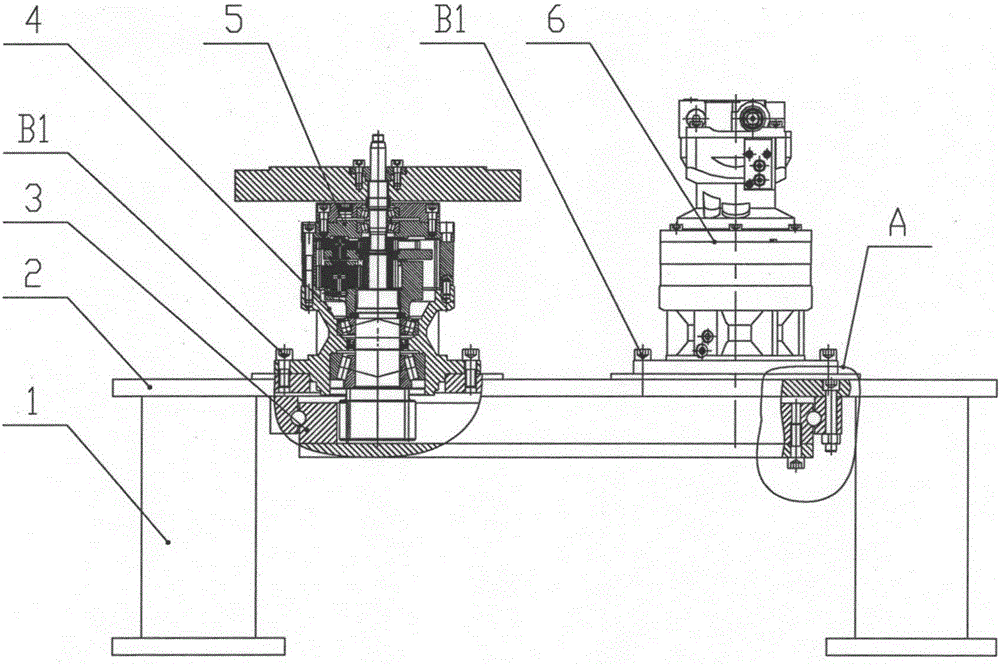

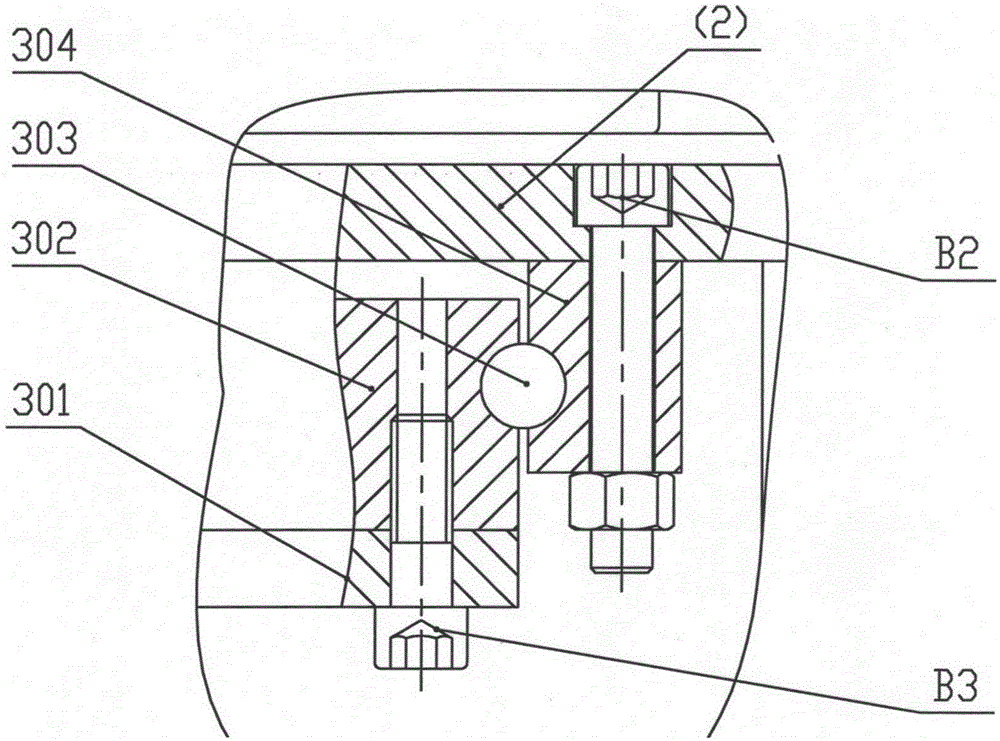

[0021] The present invention is a hydraulic motor inertia loading test device, such as figure 1 with figure 2 As shown, the platform 2 is a square, and a pillar 1 is welded at its four corners. There are three sets of bolt holes on the platform 2, which are respectively used to install the slewing support 3 and the tested hydraulic motor reducer assembly 6. and load module 5. The four pillars 1 are respectively arranged on the four corners of the platform 2, and the four pillars 1 are of the same height, and are placed on the ground to support the platform 2; the slewing support 3 is connected under the platform 2 through the second bolt B2, and the slewing support 3 includes the connection Disc 304, ring gear 302, steel ball 303 and chassis 301 four parts, such as image 3 shown. Wherein, the connection plate 304 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com