Line fixing mechanism

A technology of a wire fixing device and an auxiliary mechanism, which is applied in the installation of electrical components, cables, overhead installation, etc., can solve the problems of affecting the firmness and lasting effectiveness of wire clamping, cumbersome unlocking work, and inconvenient disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

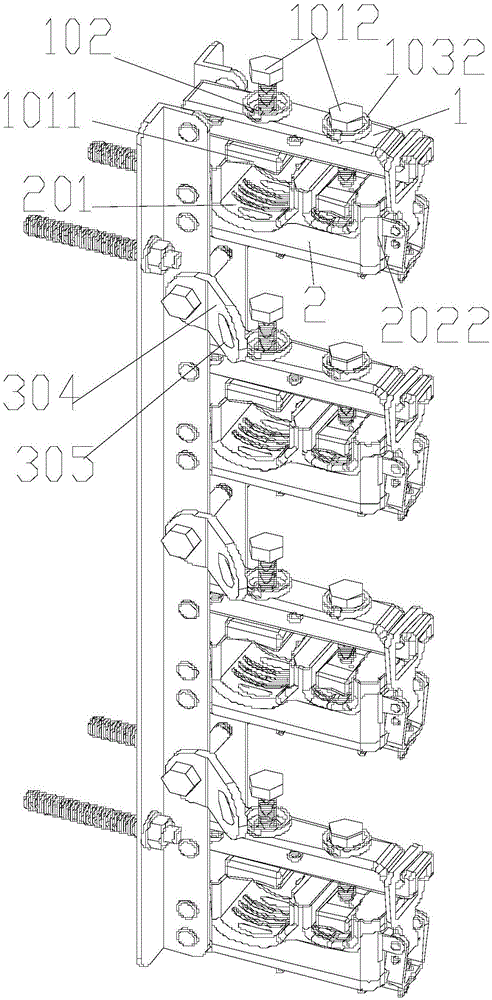

[0042] Such as Figure 1-6 As shown, a wire fixing mechanism includes a wire fixing device, the wire fixing device includes a base 3 and four wire passing devices arranged on the base 3, and a traction auxiliary mechanism arranged on the base 3 for connecting the cable pulling device .

[0043] The traction auxiliary mechanism includes three traction plates 304 which are fixedly connected with the base 3 , and each traction plate 304 is provided with a traction hole 305 .

[0044] The way that the traction plate 304 is fixedly connected to the base 3 is a detachable fixed connection through bolts.

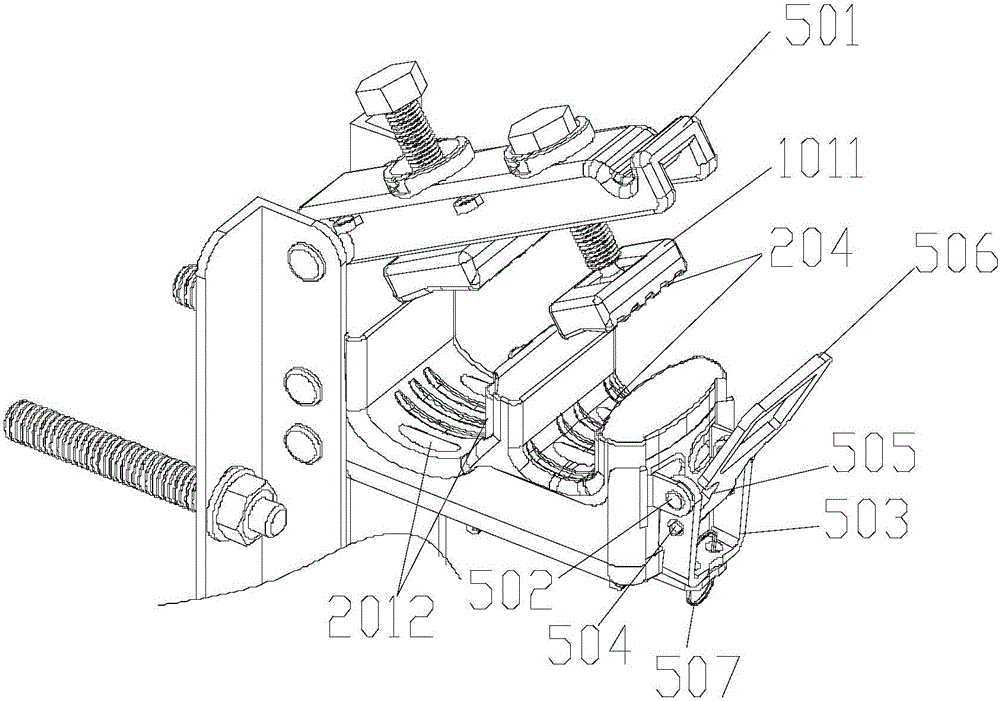

[0045] Each wire passing device includes a pair of first body 1 and second body 2, one end of the first body 1 is fixedly connected to the base 3, one end of the second body 2 is hinged to the base 3 through the first hinge shaft 301, and the second The other end of a body 1 is detachably connected to the other end of the second body 2; each first body 1 is provided with two clam...

Embodiment 2

[0069] On the basis of the technical solution of the wire fixing mechanism in embodiment 1, the following improvements have been further made:

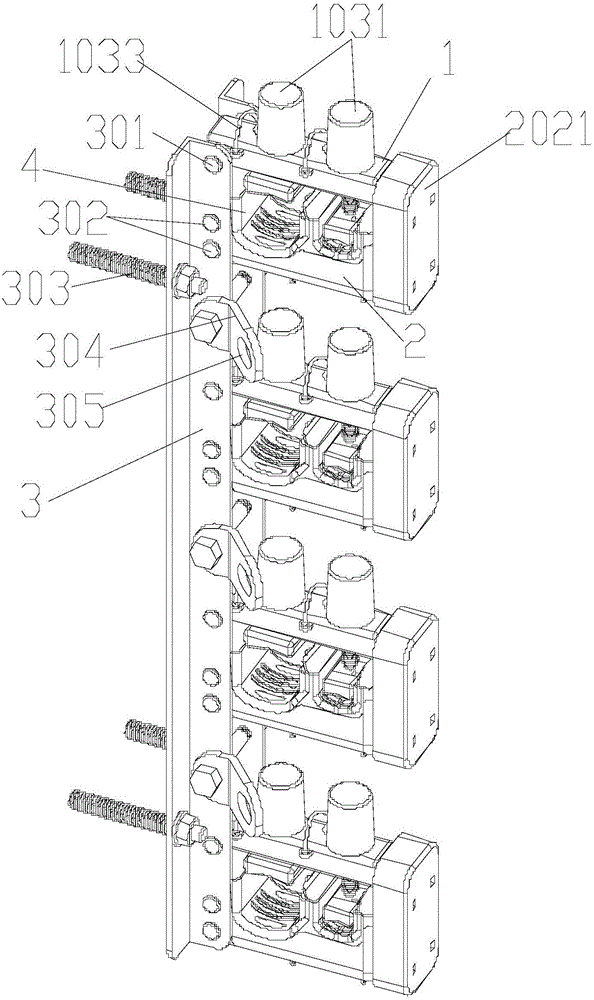

[0070] Such as Figure 1-6 As shown, a first protective cover 1031 for protecting the locking bolt 1012 is also provided on the first body 1 .

[0071] The first body 1 is also provided with a first buckle device that cooperates with the first protective cover 1031 .

[0072] The first locking device is a rotating buckle 1032 provided on the flange surrounding the locking hole 102 . During use, the first protective cover 1031 can be locked or opened with the rotating buckle 1032 by rotating it.

[0073] The first protective cover 1031 is connected to the first main body 1 through a first connecting wire 1033 , one end of the first connecting wire 1033 is fixed on the first protective cover 1031 , and the other end is fixed on the first main body 1 .

[0074] The wire fixing mechanism is also provided with a second protective cover 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com