Filter element

A technology for sealing packaging and inspection devices, which is applied to measuring devices, instruments, scientific instruments, etc., and can solve problems such as reduced quality of stored items and product damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

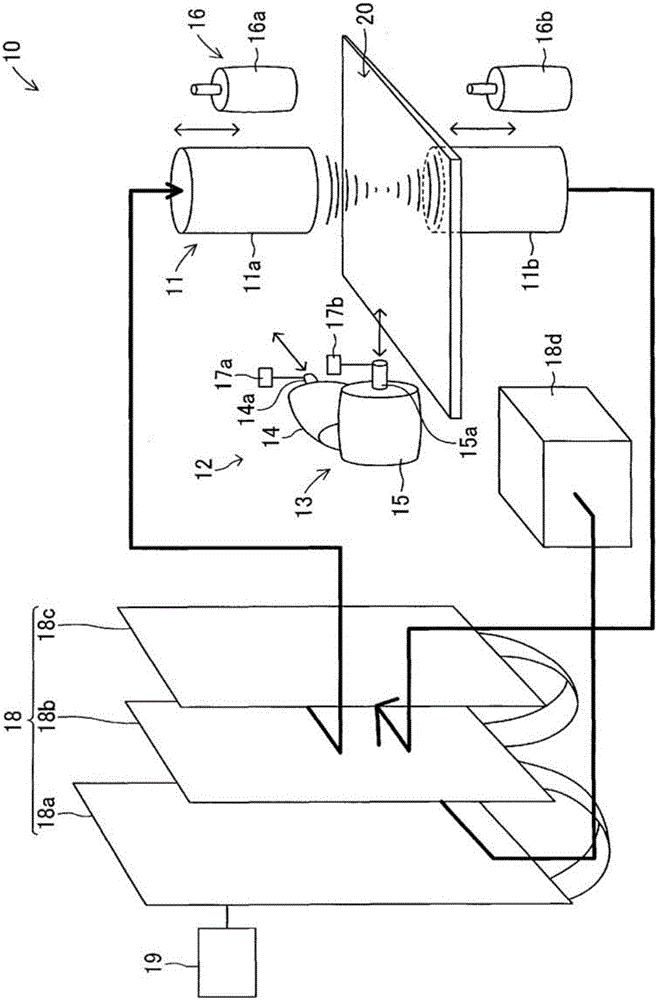

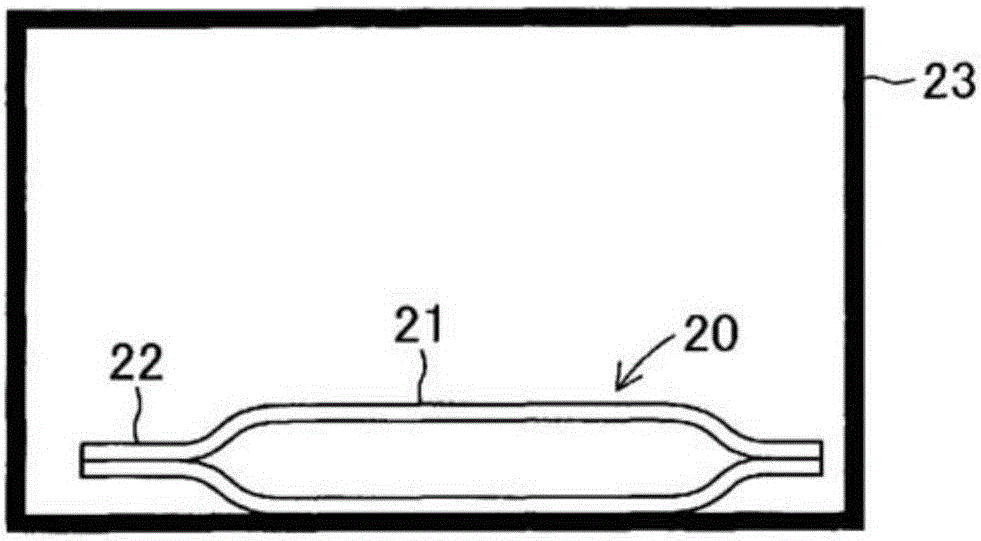

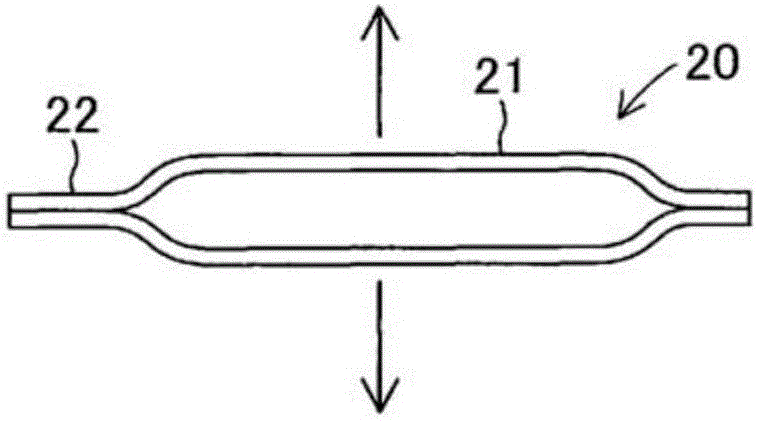

[0026] Hereinafter, one embodiment of the present invention will be described with reference to the drawings. figure 1 It shows the inspection device 10 according to this embodiment to inspect the vacuum-packed product 20 for leakage, that is, to check whether the vacuum-packed product 20 is mixed with gas such as air or foreign matter. In the following descriptions, the directions of up and down, front and back, and left and right are based on figure 1 the direction of figure 1 The lower left is the front, and the upper right is the rear. The inspection device 10 has a setting device (not shown) for setting the vacuum-packed product 20 , an ultrasonic sensor 11 , a moving device 12 for moving the ultrasonic sensor 11 , encoders 17 a , 17 b , a control device 18 , and a display device 19 .

[0027] The setting device holds the peripheral portion or the four corners of the vacuum-packaged product 20 and supports the vacuum-packed product 20 in a state where the portion other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com