High-oil barley granule compound feed with low pulverization ratio for pig and a preparation method thereof.

A technology for compound feed and pulverization rate, which is applied in the field of low pulverization rate barley and high oil type swine pellet compound feed for the preparation of reducing its particle pulverization rate, can solve the problem of restricting the use of barley raw materials and oil materials, and increasing the number of feed particles. Difficulty in forming, affecting the forming ability of feed pellets, etc., to reduce the risk of soft fat meat, optimize production process parameters, and reduce feed costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

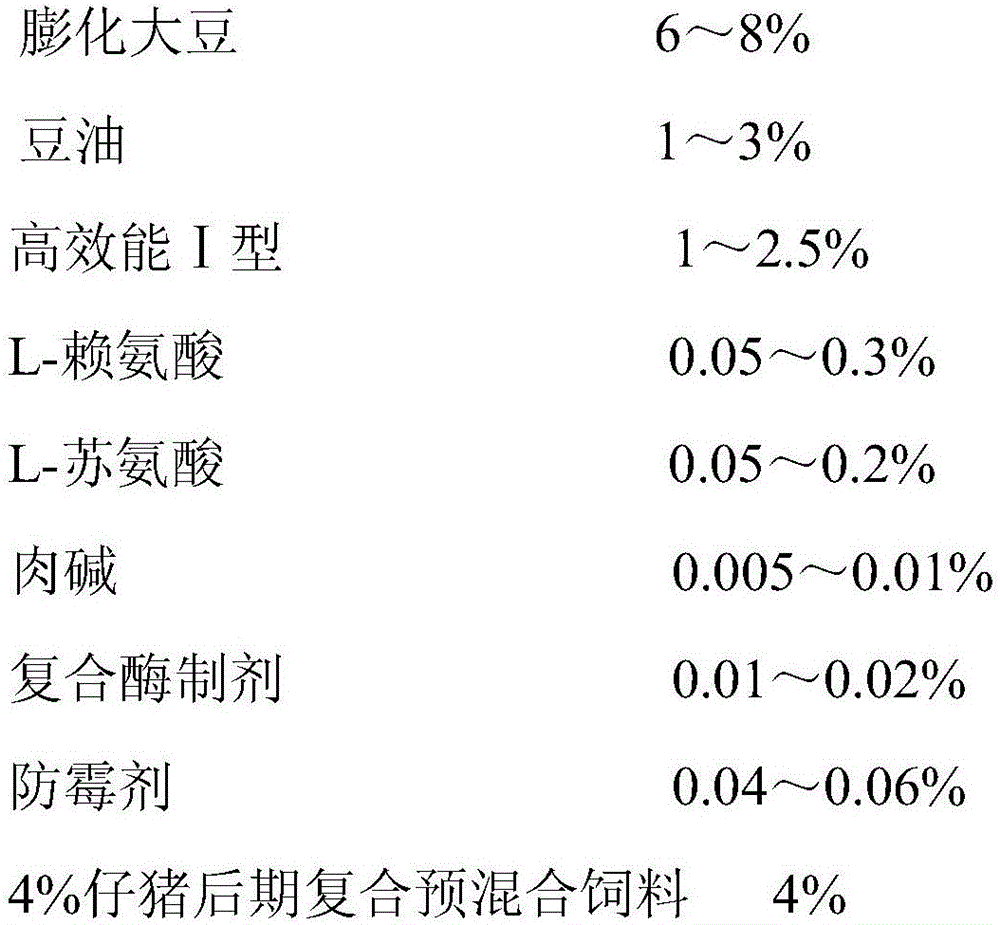

[0040] A barley high-oil pellet compound feed for pigs with a low pulverization rate, which comprises the following components in terms of mass percentage of air-dried matter:

[0041] Corn 30%, barley 35%, soybean meal 20%, puffed soybean 6%, soybean oil 2.18%, high-efficiency type I 2.5%, L-lysine 0.2%, L-threonine 0.05%, carnitine 0.005%, compound Enzyme preparation 0.015%, antifungal agent 0.05%, 4% compound premixed feed for piglets in later period 4%.

[0042] The specific preparation process of the above-mentioned pig pellet compound feed is as follows:

[0043] (1) Three cleaning of large raw materials: use three cleaning sieves to remove impurities and imperfect grains in the corn and barley raw materials in the above formula.

[0044](2) Grinding of raw materials: crush the corn and barley in the composition to 1.2-1.5 mm, and the pass rate of 20 mesh sieve is greater than 92%; the soybean meal and puffed soybeans are mixed according to the proportion required by th...

Embodiment 2

[0052] A barley high-oil pellet compound feed for pigs with a low pulverization rate, which comprises the following components in terms of mass percentage of air-dried matter:

[0053] Corn 43%, barley 33.742%, soybean meal 10%, puffed soybean 7%, soybean oil 1%, high-efficiency type I 1%, L-lysine 0.05%, L-threonine 0.15%, carnitine 0.008%, compound Enzyme preparation 0.01%, antifungal agent 0.04%, 4% compound premixed feed for piglets in later period 4%.

[0054] The specific preparation process of the above-mentioned pig pellet compound feed is as follows:

[0055] (1) Three cleaning of large raw materials: use three cleaning sieves to remove impurities and imperfect grains in the corn and barley raw materials in the above formula.

[0056] (2) Grinding of raw materials: crush the corn and barley in the composition to 1.2-1.5 mm, and the pass rate of 20 mesh sieve is greater than 92%; the soybean meal and puffed soybeans are mixed according to the proportion required by th...

Embodiment 3

[0064] A barley high-oil pellet compound feed for pigs with a low pulverization rate, which comprises the following components in terms of mass percentage of air-dried matter:

[0065] Corn 47%, barley 15%, soybean meal 20%, puffed soybean 8%, soybean oil 3%, high-efficiency type I 2.41%, L-lysine 0.3%, L-threonine 0.2%, carnitine 0.01%, compound Enzyme preparation 0.02%, antifungal agent 0.06%, 4% compound premixed feed for piglets in later period 4%.

[0066] The specific preparation process of the above-mentioned pig pellet compound feed is as follows:

[0067] (1) Three cleaning of large raw materials: use three cleaning sieves to remove impurities and imperfect grains in the corn and barley raw materials in the above formula.

[0068] (2) Grinding of raw materials: crush the corn and barley in the composition to 1.2-1.5 mm, and the pass rate of 20 mesh sieve is greater than 92%; the soybean meal and puffed soybeans are mixed according to the proportion required by the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com