A kind of method utilizing ester solvent to process polystyrene sulfonic acid resin catalyst

A polystyrene sulfonic acid and ester solvent technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, catalyst activation/preparation, etc., can solve the difficulties in the preparation of methyl chloroacetate and sodium methoxide, which are not suitable for large-scale production and other issues to achieve the best reactivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

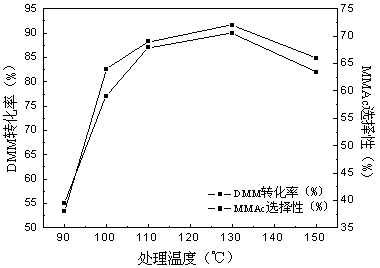

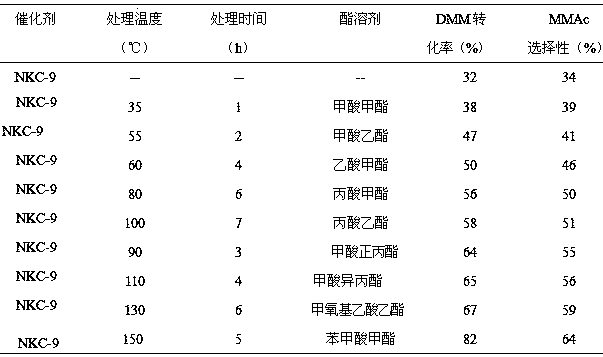

[0035] Put 10 grams of NKC-9 sulfonic acid resin catalyst into 100 mL containing ester solvent (methyl formate, ethyl formate, methyl acetate, methyl propionate, ethyl propionate, n-propyl formate, isopropyl formate Esters, ethyl methoxyacetate, methyl benzoate, etc.) in the reactor, in the temperature range of 35-150 ℃ to treat the sulfonic acid resin catalyst for 1-7 h. After the treated catalyst was filtered, it was dried in an oven at 120 °C for 6 h. The evaluation conditions of the catalyst were as follows: Weigh 30 mL of DMM, 30 mL of 1,4-dioxane solvent, and 1 g of the modified sulfonic acid resin catalyst into the reaction kettle respectively, and use N 2 Replace the air in the kettle three times under the condition of 1.0 MPa, so that the remaining air content in the kettle is less than 0.1 %, pass in 3.0 MPa CO, let it stand for 30 minutes, and use it for leak detection of the reactor to ensure that the device is airtight and then emptied Gas in the kettle. The sti...

Embodiment 2

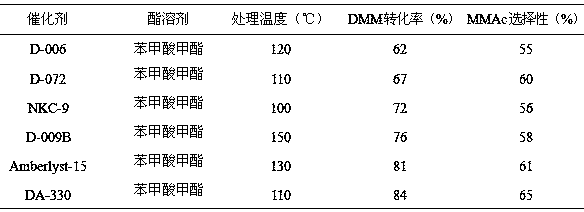

[0040] Put 10 grams of different types of polystyrene sulfonic acid resin catalysts (D-009B, DA-330, D-006, D-072, Amberlyst-15, NKC-9) into a 100mL reaction kettle containing methyl benzoate solvent , at 100-150°C, 5.0 MPa, and CO atmosphere for 6 h. After the treated catalyst was filtered, it was dried in an oven at 120 °C for 6 h. The evaluation conditions of the catalyst were as follows: Weigh 30 mL of DMM, 30 mL of 1,4-dioxane solvent, and 1 g of the modified sulfonic acid resin catalyst, and add them to the reaction kettle respectively, and use N 2 Replace the air in the kettle three times under the condition of 1.0 MPa, so that the remaining air content in the kettle is less than 0.1%, pass in 3.0 MPa CO, let it stand for 30 minutes, and use it for leak detection of the reactor to ensure that the device is not leaking and then emptied Gas in the kettle. The stirring speed of the reactor was 500 rpm, 3.0 MPa CO was introduced, the reaction temperature was controlled at...

Embodiment 3

[0045] Put 10 grams of DA-330 catalyst into a 100 mL reaction kettle containing methyl benzoate solvent, and treat it at 110 °C, 5.0 MPa, and CO atmosphere for 0.5-20 h. After the treated catalyst was filtered, it was dried in an oven at 120 °C for 6 h. The evaluation conditions of the catalyst were as follows: Weigh 30 mL of DMM, 30 mL of 1,4-dioxane solvent, and 1 g of the modified sulfonic acid resin catalyst, and add them to the reaction kettle respectively, and use N 2 Replace the air in the kettle three times under the condition of 1.0 MPa, so that the remaining air content in the kettle is less than 0.1 %, pass in 3.0 MPa CO, let it stand for 30 minutes, and use it for leak detection of the reactor to ensure that the device is airtight and then emptied Gas in the kettle. The stirring speed of the reactor was 500 rpm, 3.0 MPa CO was introduced, the reaction temperature was controlled at 110 °C, and the reaction was carried out for 6 hours. Cool down to room temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com