Method and system for food waste treatment and residual oil supervision and recovery

A kitchen waste and recycling system technology, applied in separation methods, chemical instruments and methods, grease/oily substance/float removal devices, etc., can solve problems such as unreasonable structure, inflow of kitchen waste, threats to healthy life, etc. To achieve the effect of recycling and control, convenient use and maintenance, and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] Below in conjunction with accompanying drawing, the present invention will be further described by examples.

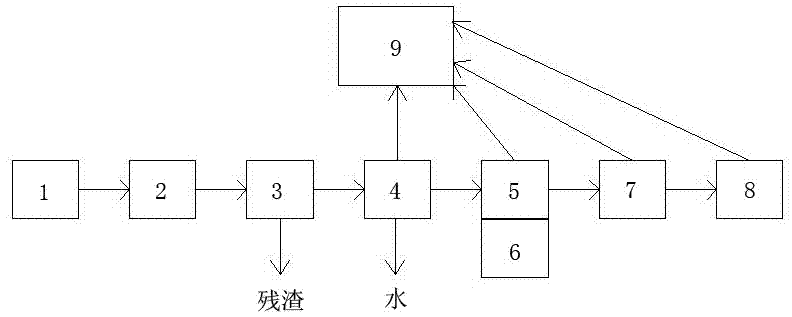

[0076] Refer to attached figure 1 , a food waste treatment and residual oil supervision recovery system, including: dining table storage trolley 1, electric push rod type self-unloading assembly 2, screw-in solid-liquid separation and dehydration device 3, airtight oil-water separator 4, chip identification transfer Barrel 5, tank car for residual oil transport 6, storage separation tank 7, product sales 8 and data center of the management department 9; table storage trolley 1 is matched with electric push rod type self-unloading assembly 2, and electric push rod type self-unloading assembly 2 is connected Screw in the solid-liquid separation and dehydration device 3, the screw-in solid-liquid separation and dehydration device 3 is connected to the airtight oil-water separator 4, the airtight oil-water separator 4 matches the chip identification identification ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com