Industrial wastewater drying method and industrial wastewater drying system

A technology for drying industrial wastewater, applied in chemical instruments and methods, energy wastewater treatment, water/sewage treatment, etc., can solve the problems of high energy consumption in the treatment process and heat-sensitive salts that cannot be reused, and achieve low operating costs and considerable Economic benefits, the effect of solving environmental problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

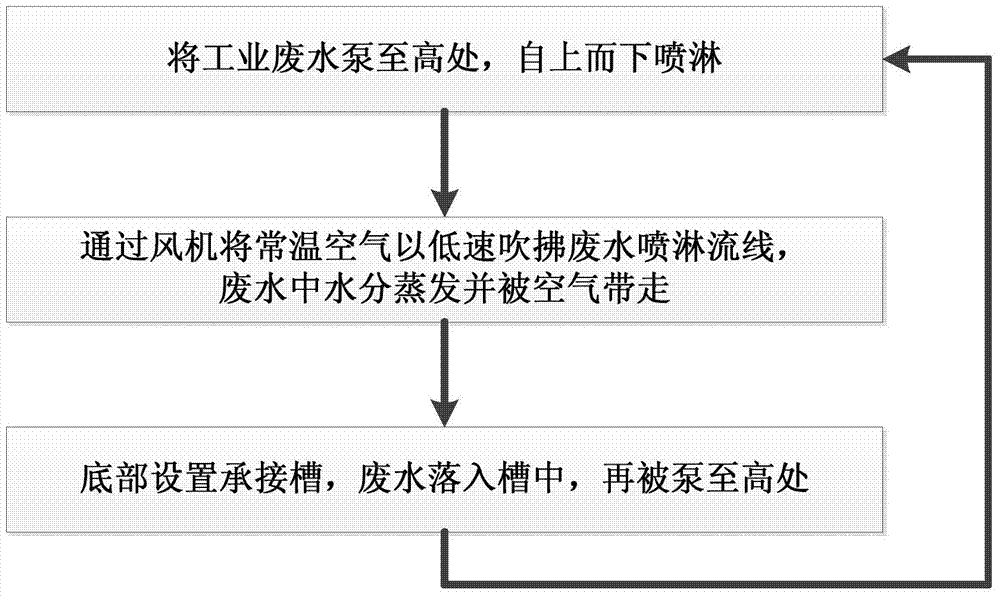

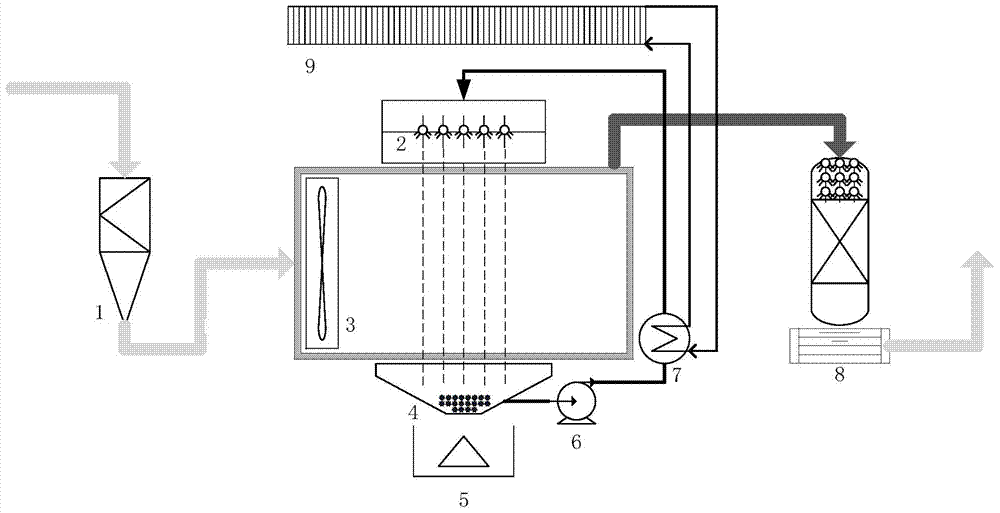

[0025] Such as figure 1 As shown, the industrial wastewater drying method disclosed in the present invention, especially the drying method of industrial salt wastewater, uses low-speed normal temperature air to dry the wastewater, that is, the industrial wastewater is first pumped to a high place, from top to bottom Use the wastewater spraying device to spray to form the wastewater spraying streamline; at the same time, the normal temperature air is blown to the wastewater spraying streamline at a low speed by the fan, so that the water in the wastewater evaporates and is taken away by the air; at the bottom of the wastewater spraying area A receiving tank is set up so that the waste water sprayed after being blown by normal temperature air falls into the receiving tank, and then pumped to a high place; this is repeated until the industrial wastewater is air-dried or concentrated. The air that has absorbed the moisture of industrial wastewater is discharged into the outside ai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com